Super junction device and manufacturing method thereof

A technology of superjunction device and manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor device, electrical components, etc., can solve the problem of inability to improve the reverse recovery soft factor of the device body diode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1 of the present invention super junction device:

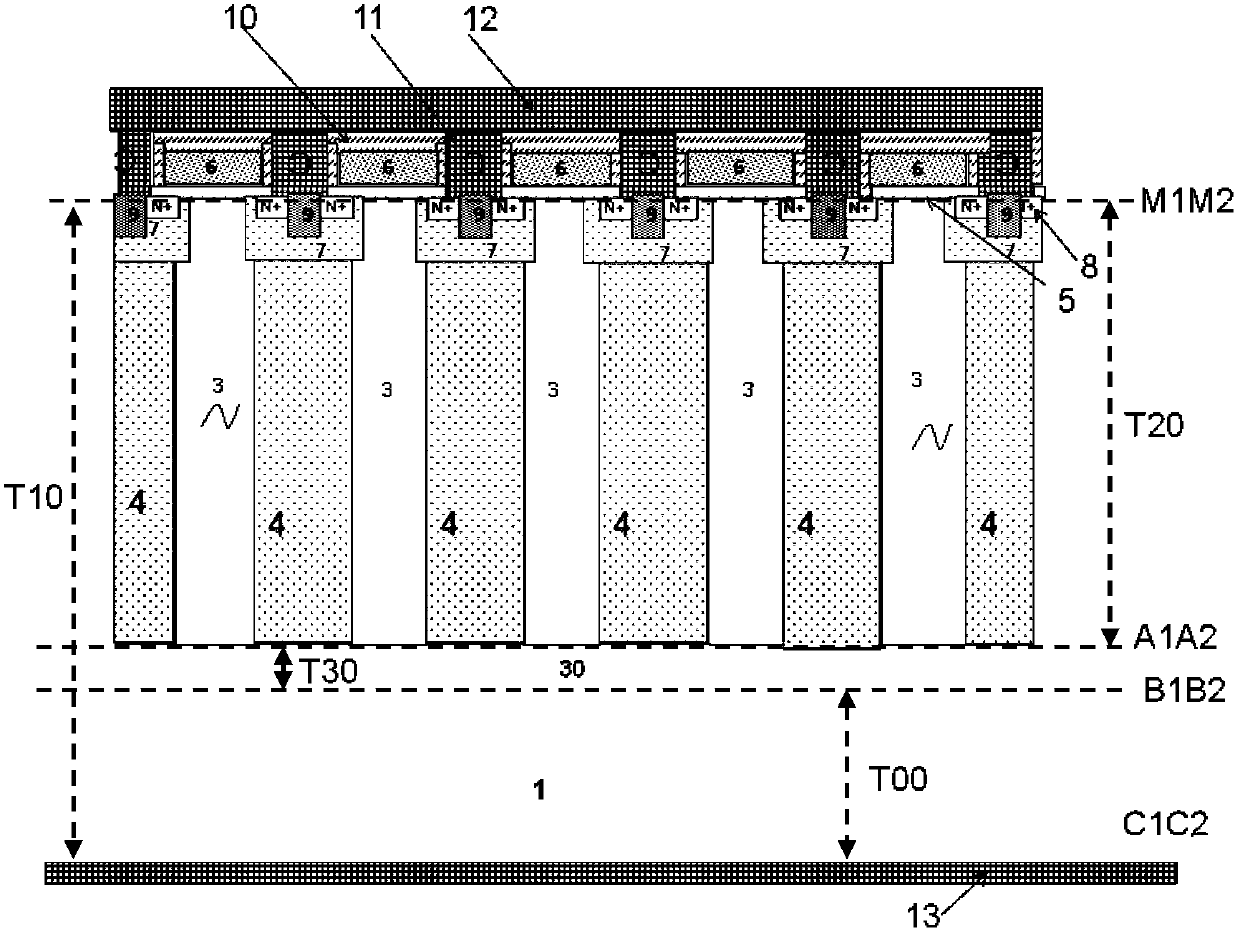

[0084] Such as image 3 Shown is a schematic diagram of a super junction device in Embodiment 1 of the present invention; in Embodiment 1 of the present invention:

[0085] The charge flow region includes a super junction structure composed of a plurality of alternately arranged N-type pillars 3 and P-type pillars; each of the N-type pillars 3 and its adjacent P-type pillars form a super-junction unit.

[0086] The super junction structure is formed on an N-type epitaxial layer, and an N-type buffer layer 30 composed of an N-type epitaxial layer is formed at the bottom of the super-junction structure, and the bottom of the N-type buffer layer 30 is heavily doped N-type semiconductor substrate 1.

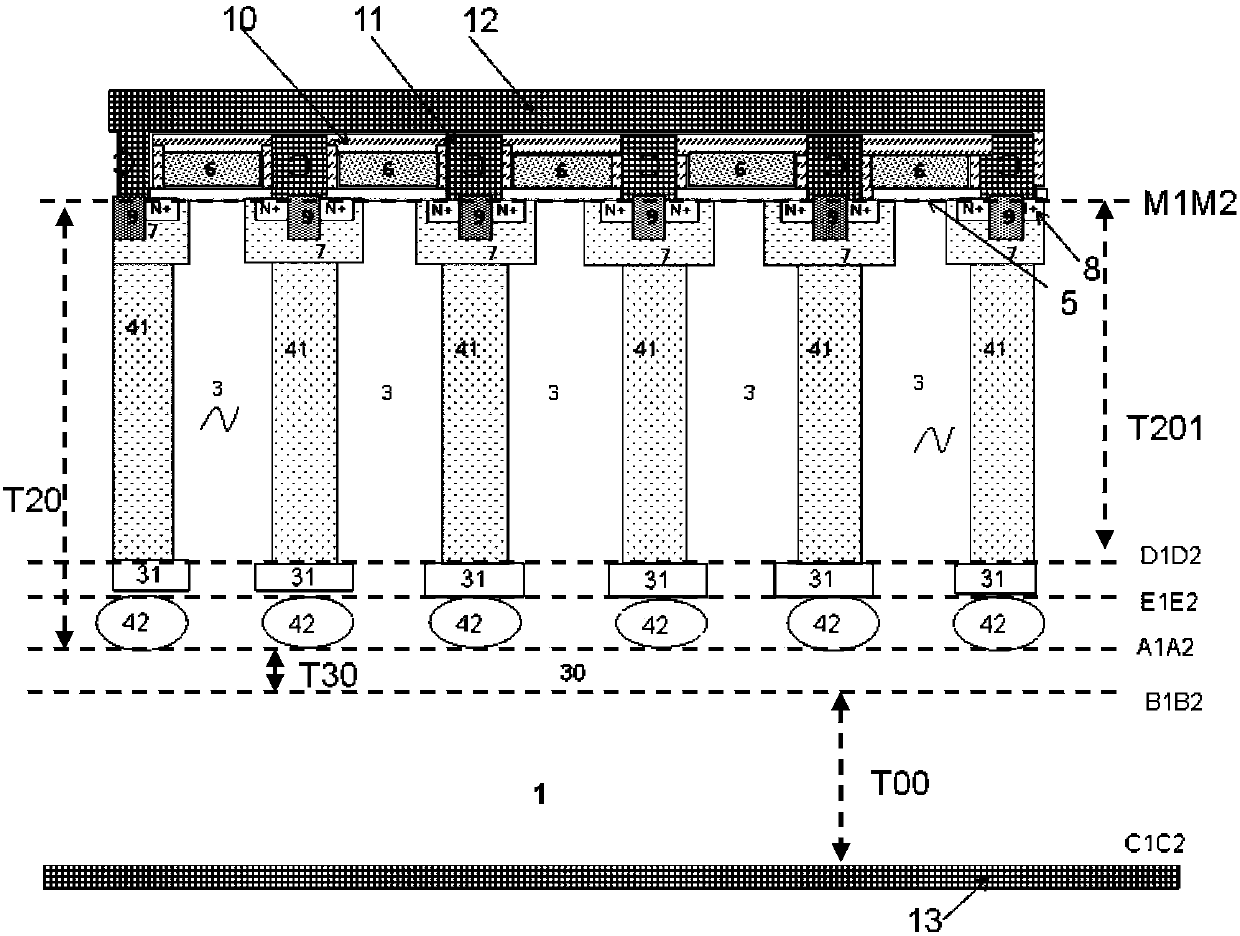

[0087] There is an N-type electric field blocking layer 31 in the P-type column of at least one super junction unit, image 3 It is shown in that all the P-type pillars include an N-type electric field blocking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com