Sheet material carrying tool

A sheet and fixture technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as easy bumps, instability of silicon wafers carried by flower baskets, affecting cleaning or processing effects, etc., to avoid bump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

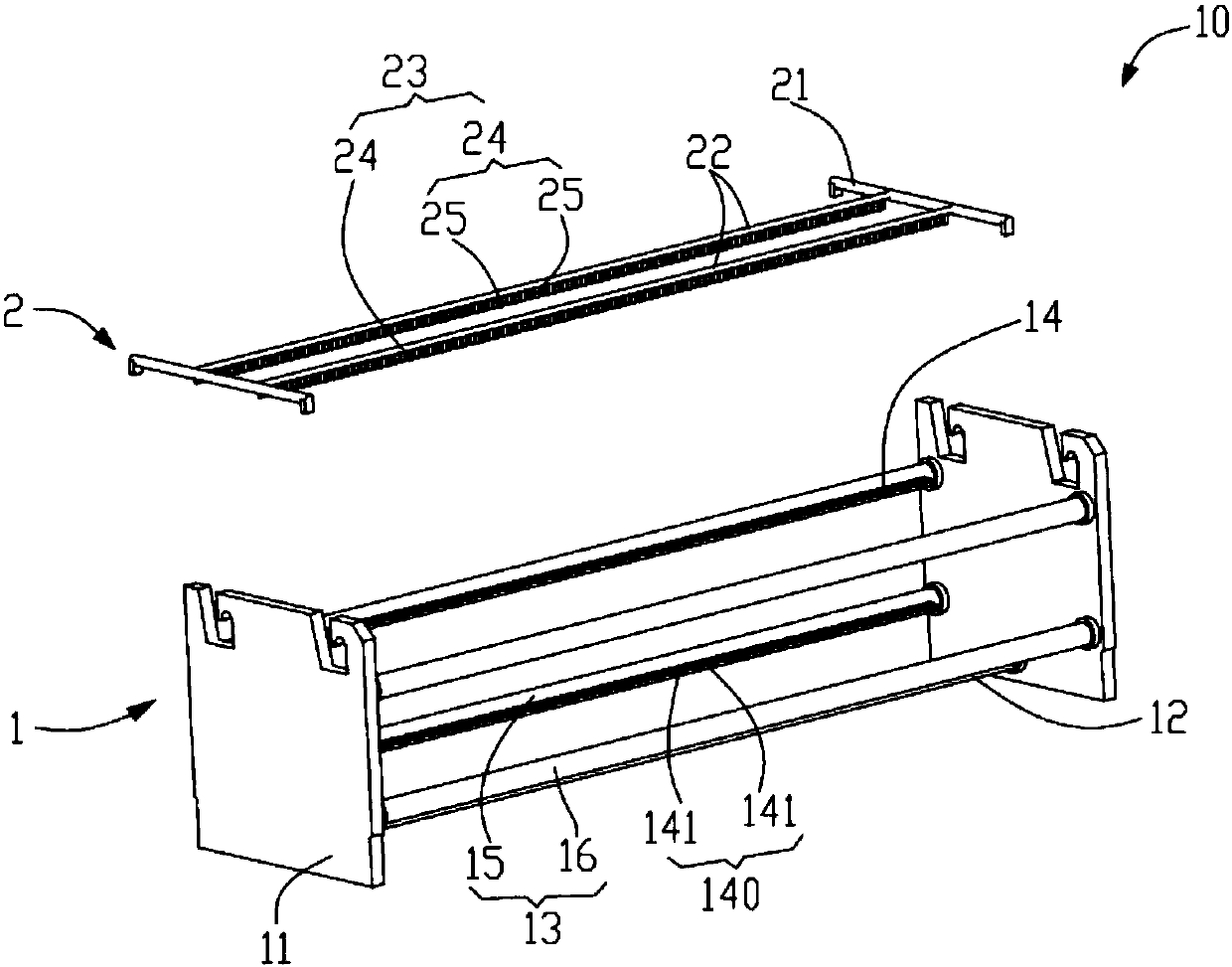

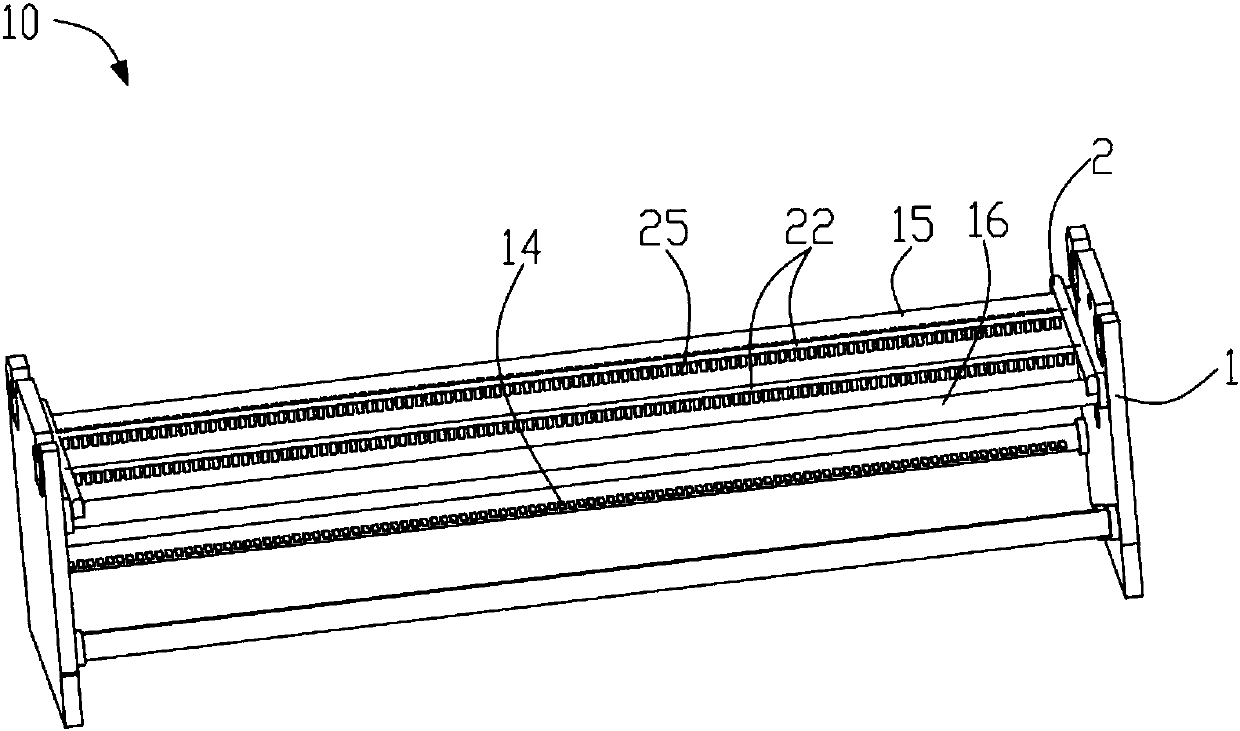

[0020] The structure of the sheet material carrying jig 10 provided by the present invention is as follows: figure 1 with figure 2 As shown, it is used to carry multiple sheets at the same time. The sheet carrying jig 10 includes a carrying frame 1 and a cover 2 that cooperate with each other.

[0021] The carrier frame 1 includes two carrier plates 11 , at least one carrier rod 12 , at least one pair of support rods 13 and a stop assembly 14 . The two carrier boards 11 are arranged opposite to each other. At least one load bar 12 and at least one support bar pair 13 are installed between the two carrier plates 11 . The carrying bar 12 carries the sheet from the bottom. At least one pair of support rods 13 supports the sheet from both sides of the sheet. In this embodiment, there is one carrying rod 12 and two supporting rod pairs 13 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap