Battery module

A battery module and battery core technology, applied in battery pack components, circuits, electrical components, etc., can solve problems such as poor thermal conductivity and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

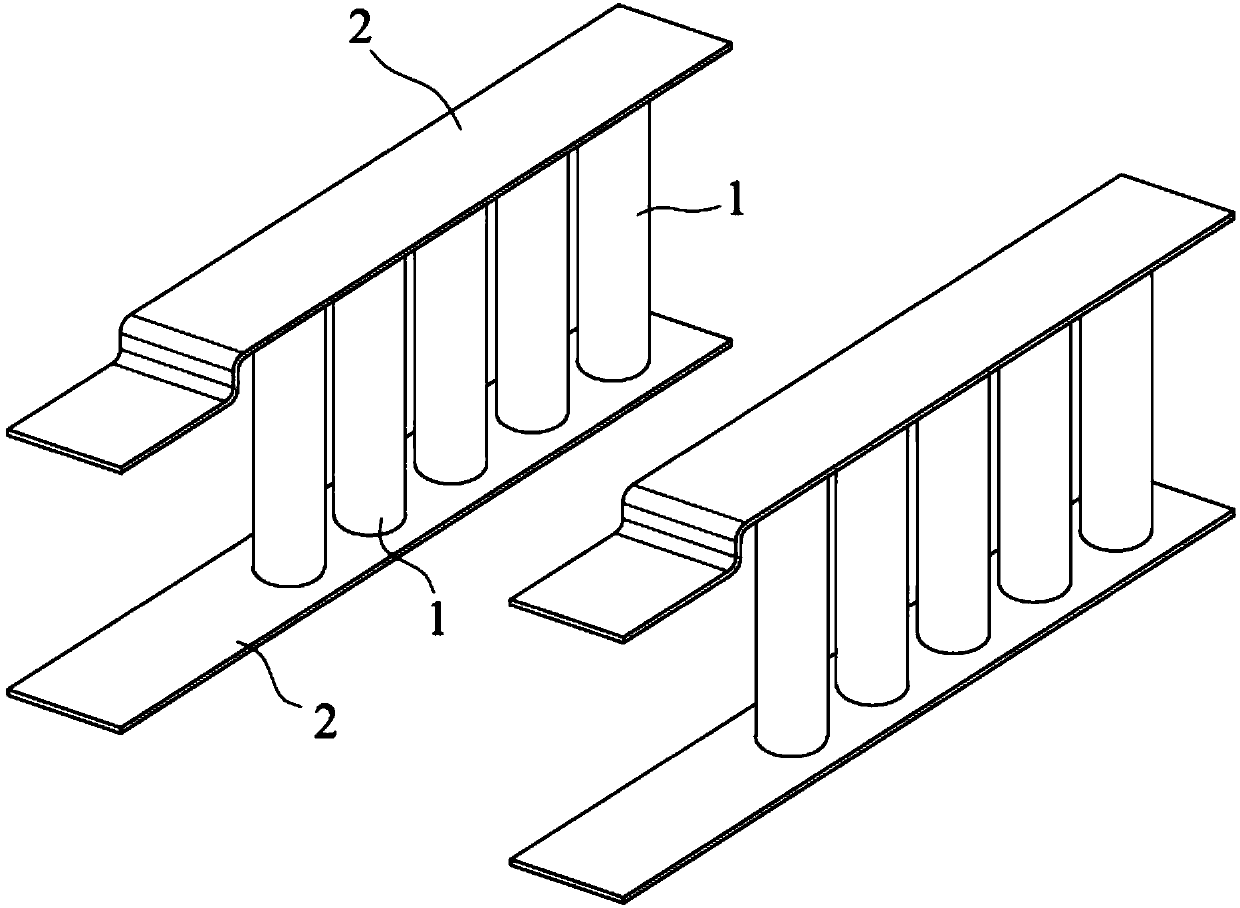

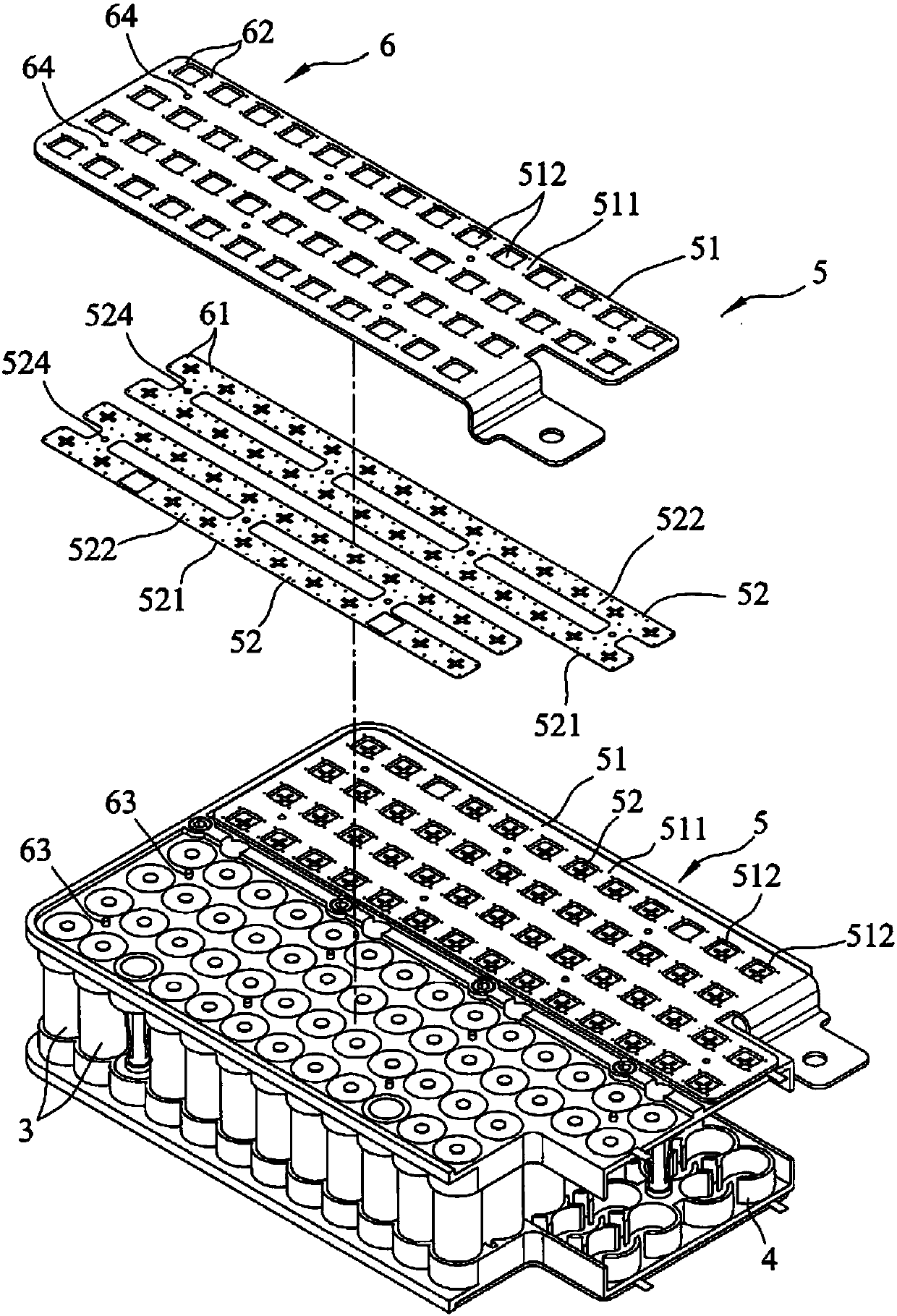

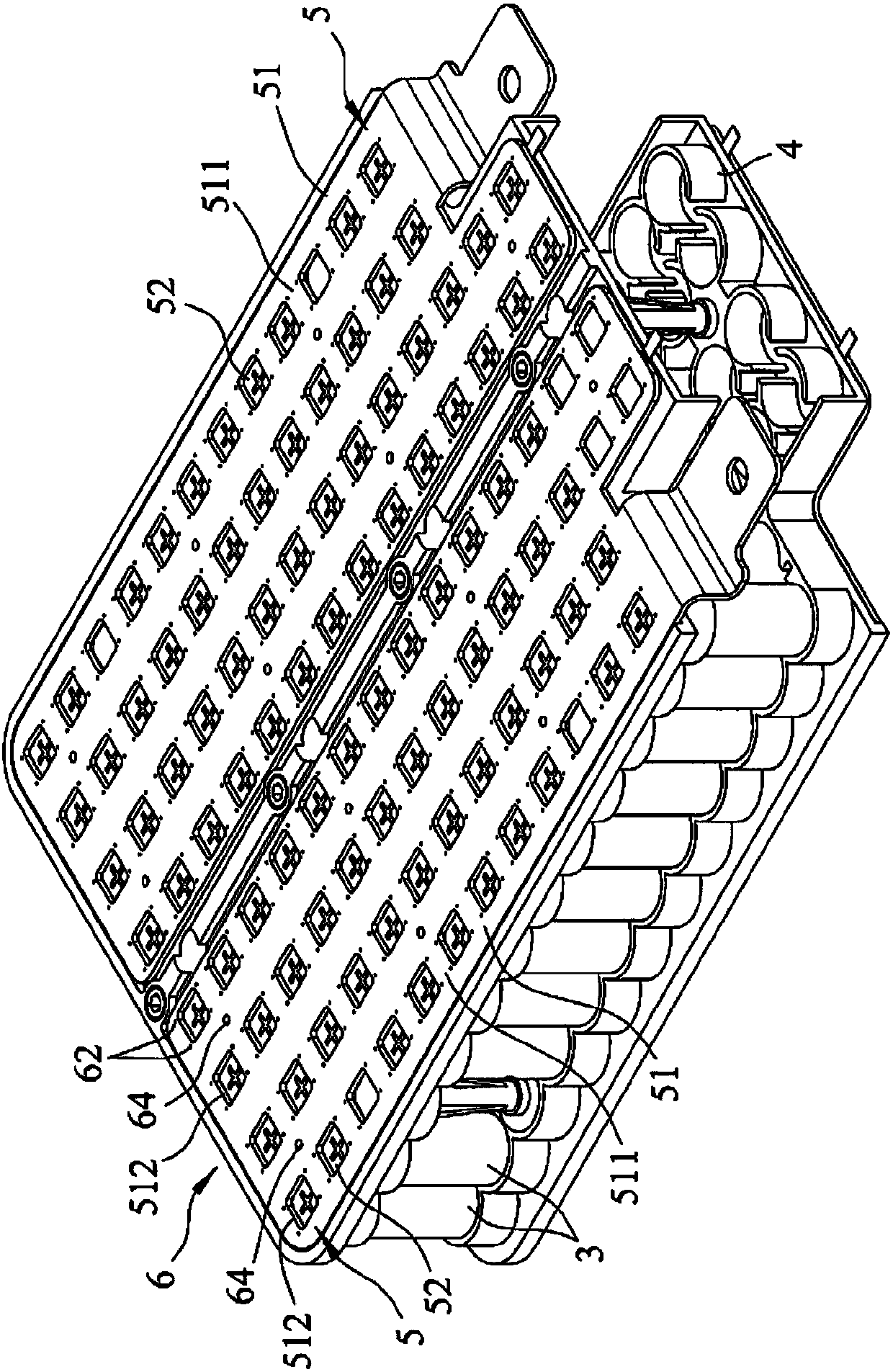

[0034] refer to figure 2 , 3 , a first embodiment of the battery module of the present invention, comprising a plurality of battery cores 3, a frame 4 for accommodating the plurality of battery cores 3, and four respectively fixed to the plurality of battery cores 3 and forming electrical Connected conductive pads 5 (only two are visible due to angular relationship).

[0035] Each conductive electrode sheet 5 includes a conductive body 51 having a conductive portion 511 and a plurality of through holes 512 , and two welding bodies 52 , and each welding body 52 has a first welding surface 521 and a second welding surface 522 . The thickness of the plurality of welding bodies 52 is smaller than that of the plurality of conductive bodies 51 , and the material of the plurality of conductive bodies 51 is red copper, and the material of the plurality of welding bodies 52 is nickel. The plurality of through holes 512 respectively correspond to the positions of the plurality of bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com