Motor controller busbar capacitor charge-discharge circuit

A charge-discharge circuit and motor controller technology, which is applied to battery circuit devices, current collectors, circuit devices, etc., can solve the problems of slow passive discharge and discharge speed, inconsistent control coordination, and burnt pre-charge relays, etc., to achieve faster discharge speed, The effect of safe and effective charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

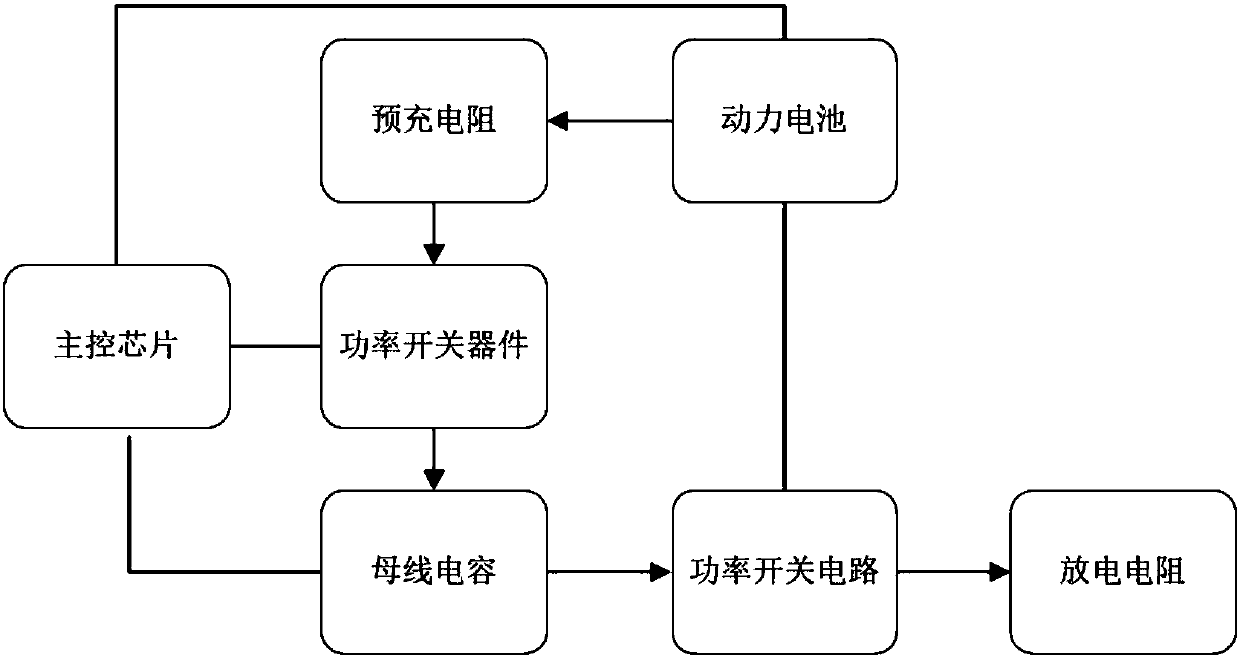

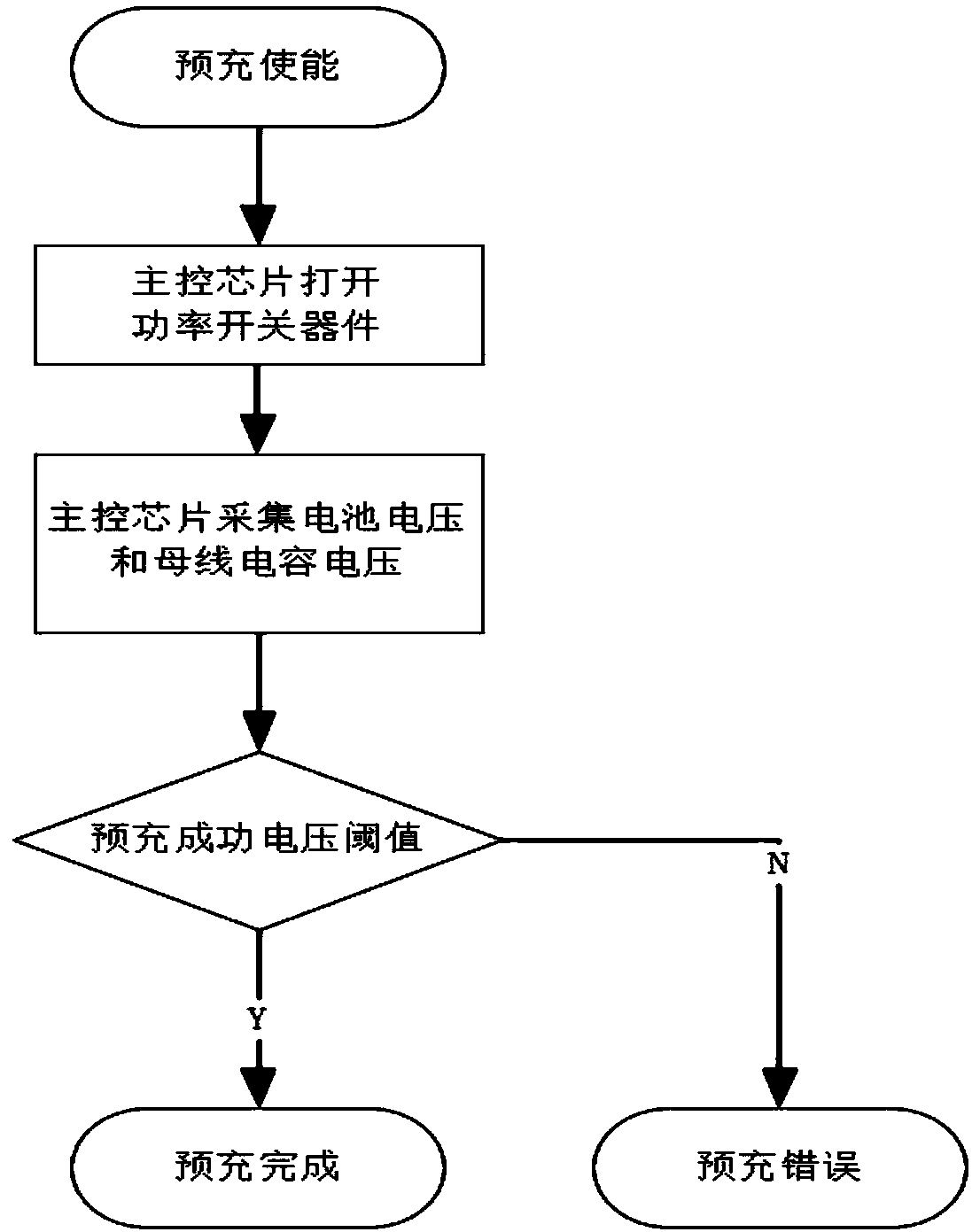

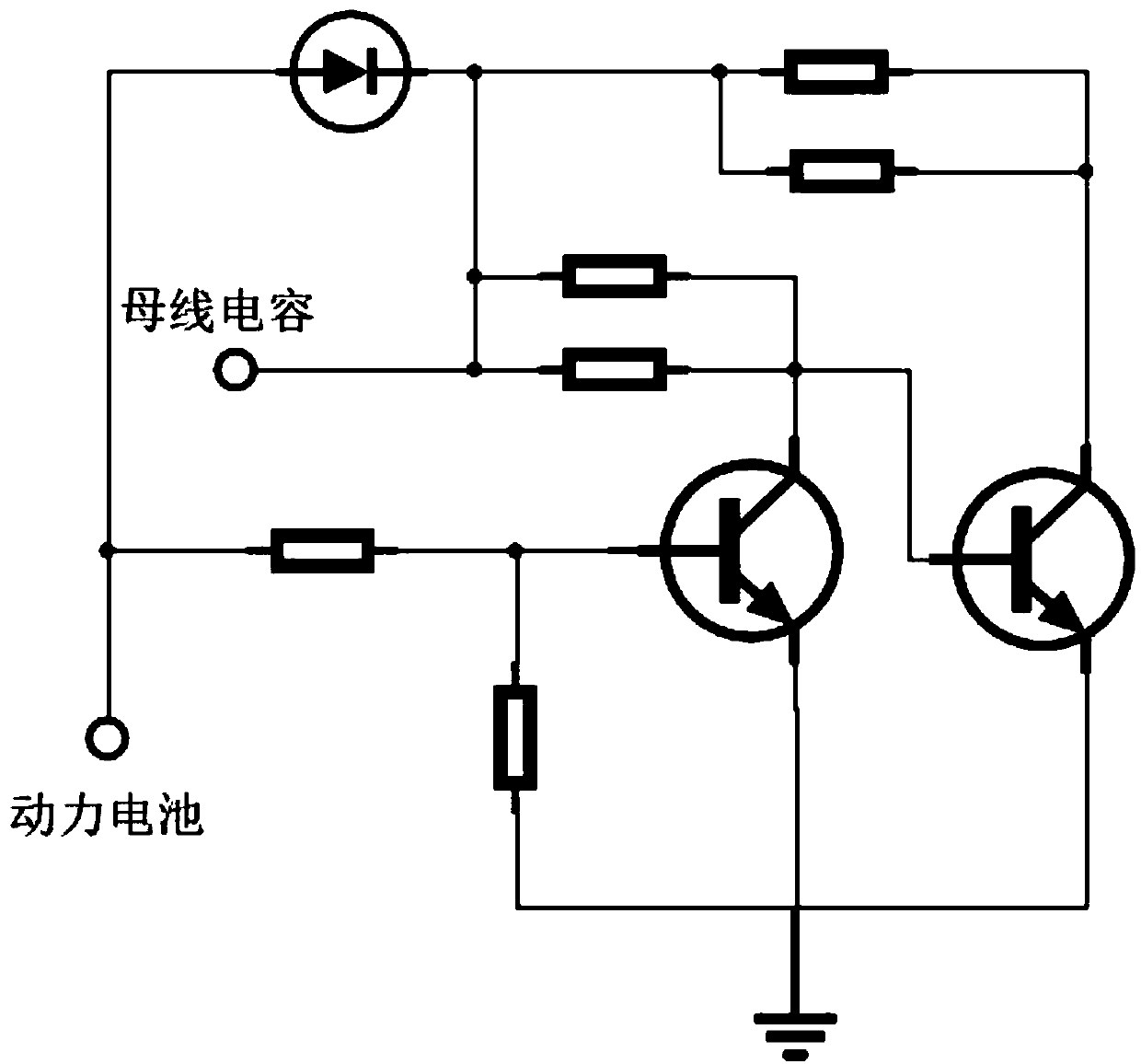

[0022] Such as figure 1 As shown, a motor controller bus capacitor charging and discharging circuit includes a power battery, a pre-charging resistor, a power switching device, a main control chip, a bus capacitor, a power switching circuit, and a discharging resistor;

[0023] The power battery is electrically connected to the pre-charging resistor, the pre-charging resistor is electrically connected to the power switch device, the power switch device is electrically connected to the bus capacitor, and the bus capacitor is connected to the power switch circuit Electrically connected, the power switch circuit is electrically connected to the discharge resistor;

[0024] The main control chip is in control connection with the power battery, the power switch device and the bus capacitor, and the power battery is electrically connected with the power switch circuit.

[0025] Wherein, the pre-charging resistance is composed of two or three resistances connected in parallel.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com