Cable insulation compositions comprising a phosphorus-containing antioxidant

An anti-oxidant and composition technology, applied in the direction of insulators, insulated conductors, insulated cables, etc., can solve the problems of filter fouling, reduced running length, and reduced yield of EHV grades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

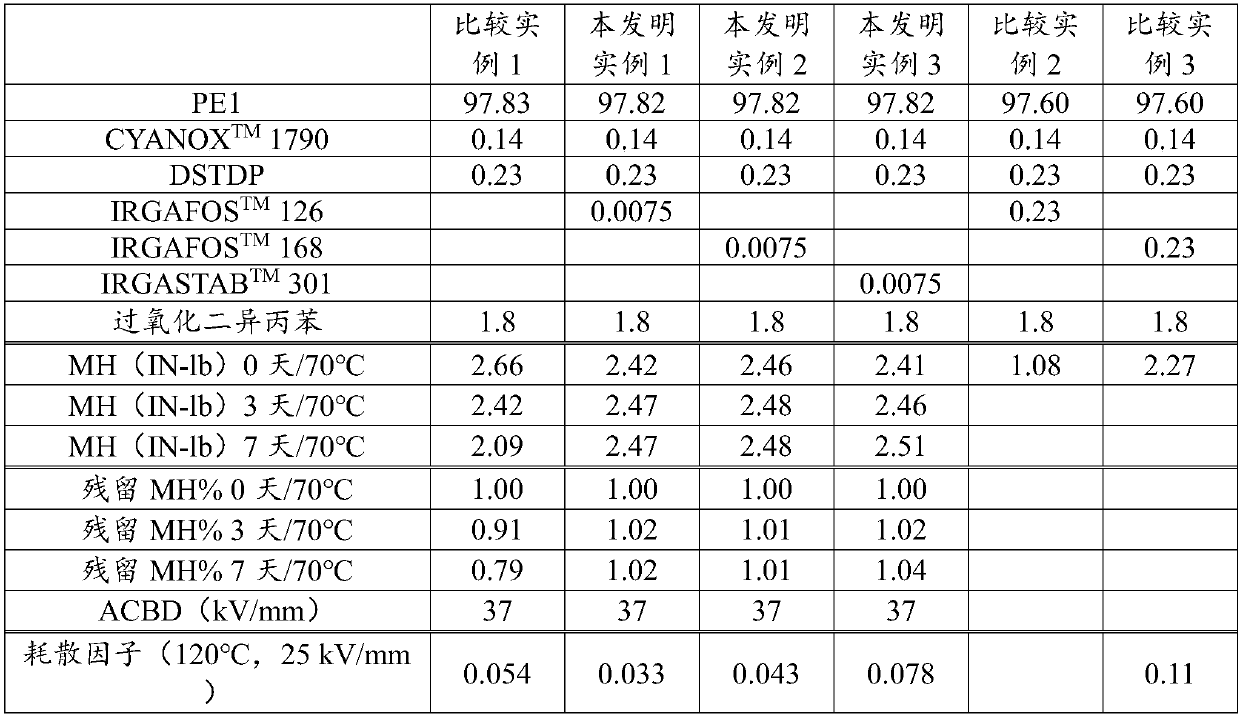

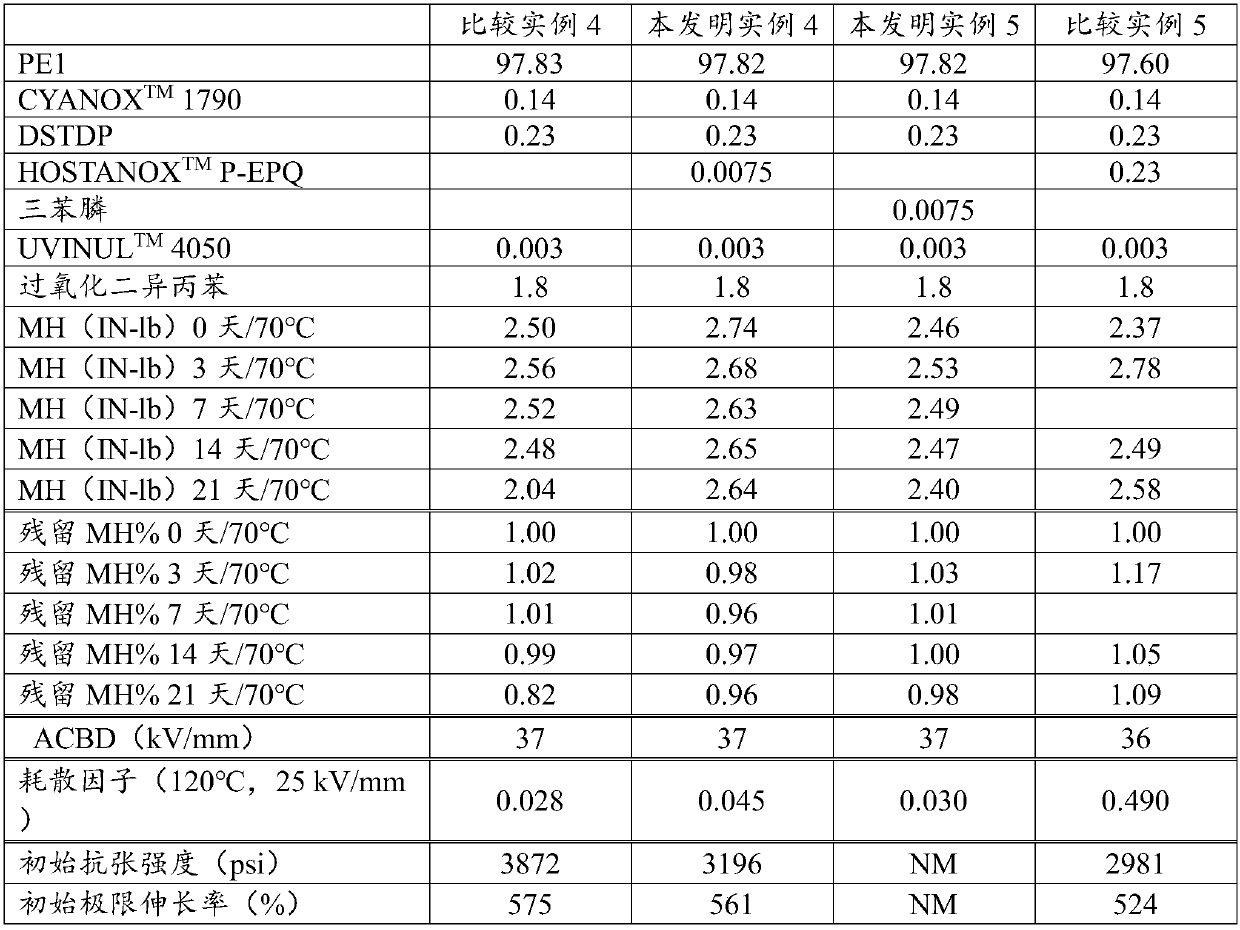

[0071] testing method

[0072] According to ASTM D1238, Condition 190°C / 2.16 kilogram (kg) weight (formerly known as "Condition E" and also known as I 2 ) for polyethylene melt index (MI) measurements and are reported in grams dissolved per 10 minutes. Melt index is inversely proportional to the molecular weight of the polymer. Thus, the higher the molecular weight, the lower the melt index, although the relationship is not linear.

[0073] Density was measured by the procedure of ASTM D792, Method B. Report results in grams (g) per cubic centimeter or g / cc.

[0074] MH (Maximum Torque) was measured on a Moving Die Rheometer (MDR) according to ASTM D-5289.

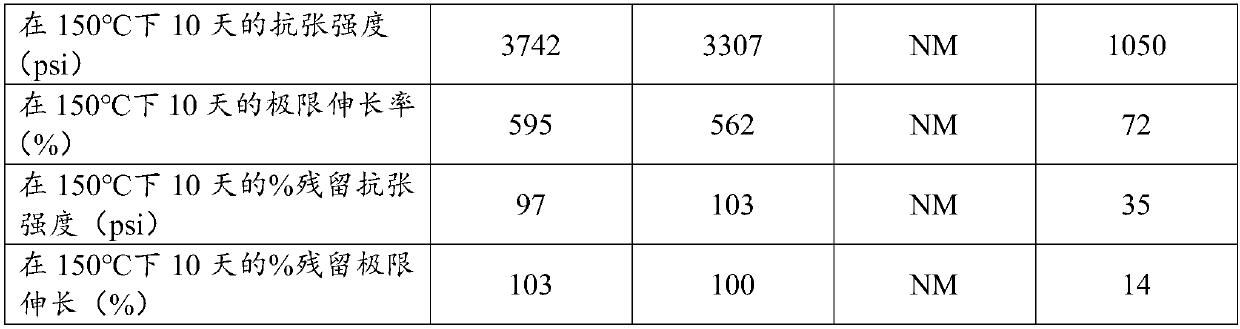

[0075] To evaluate the long-term heat aging performance, the cross-linked samples were aged at 150°C in air for 10 days and 21 days, and the INSTRON TM Tensile strength and ultimate elongation were analyzed on a 4201 machine.

[0076] Initial tensile strength (psi) was measured by ASTM D638.

[0077] Initial ultima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com