A Roller Ring Die Granulator

A ring-die granulator and roller-type technology, applied in the direction of die extrusion granulation, etc., can solve the problems of bulkiness, unsatisfactory granulation effect, low compactness of biomass particles, etc., to simplify the equipment structure and compactness. Controllable and weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

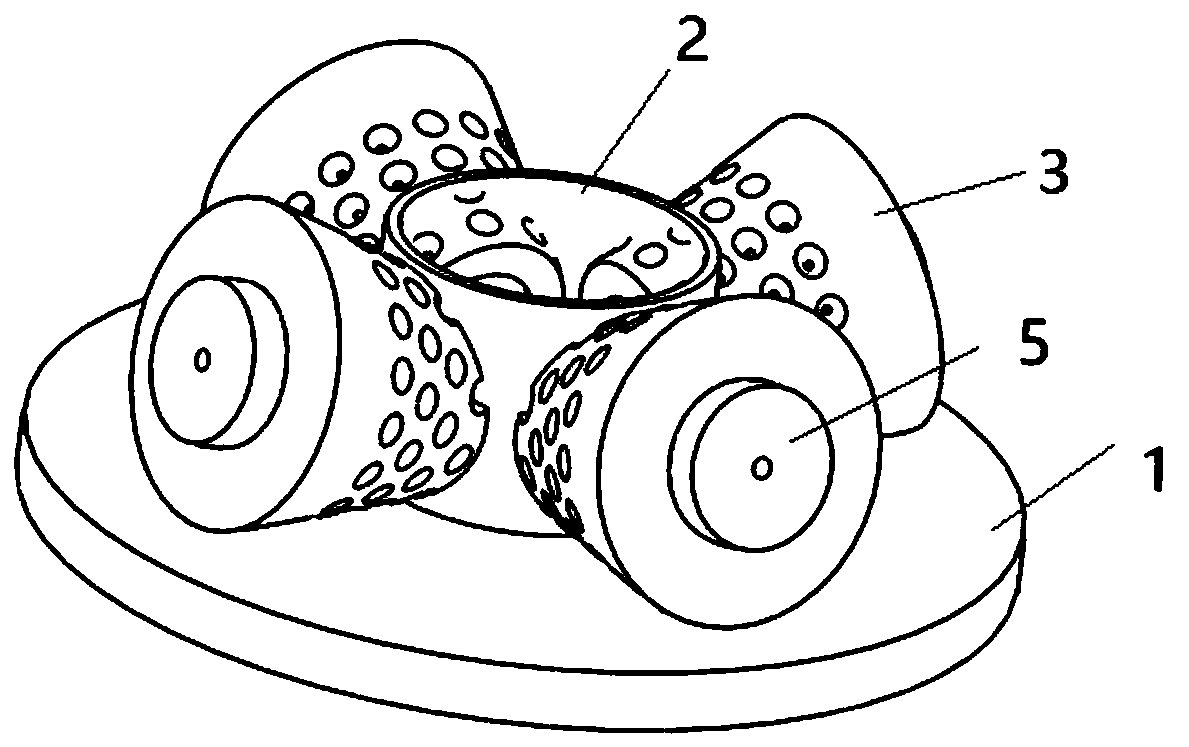

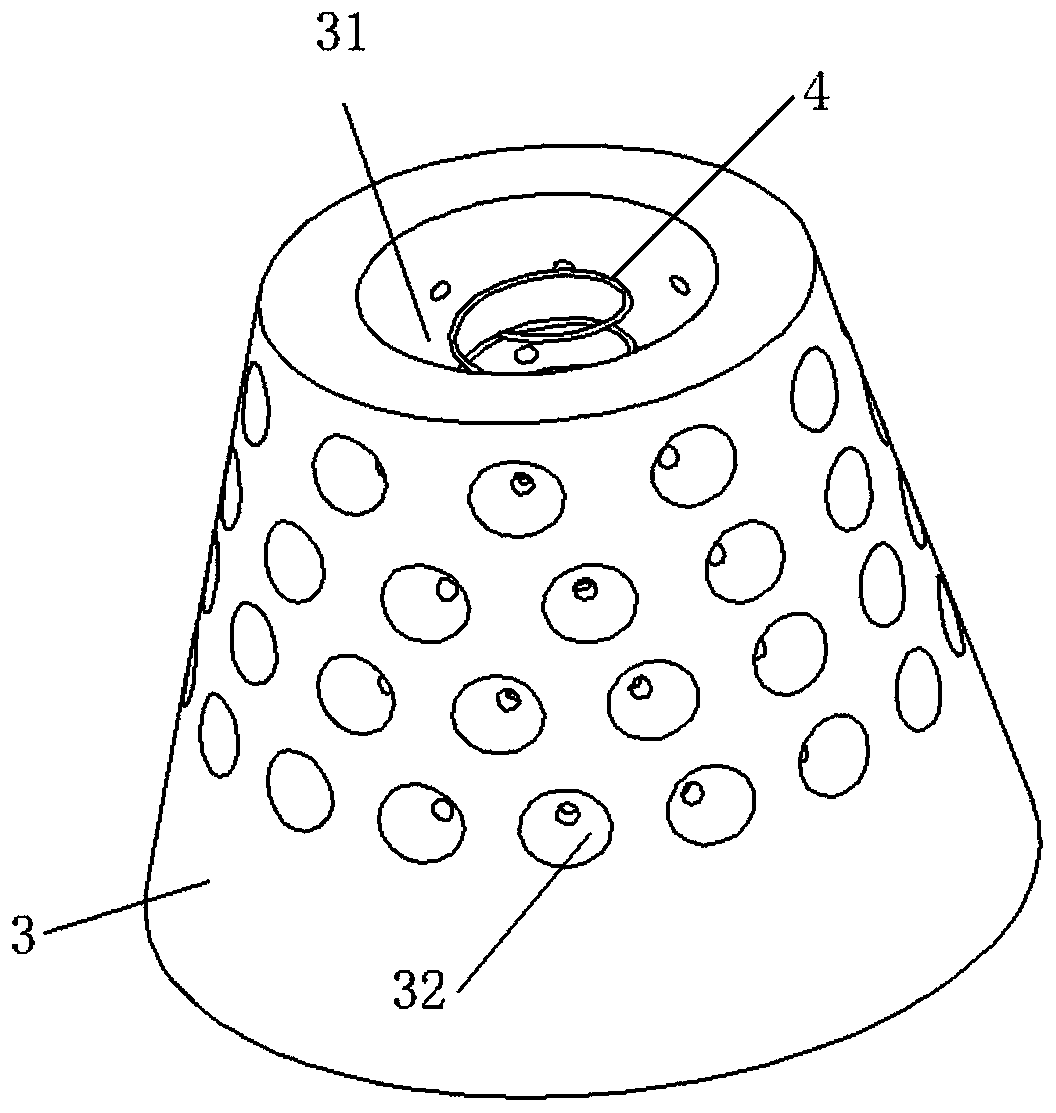

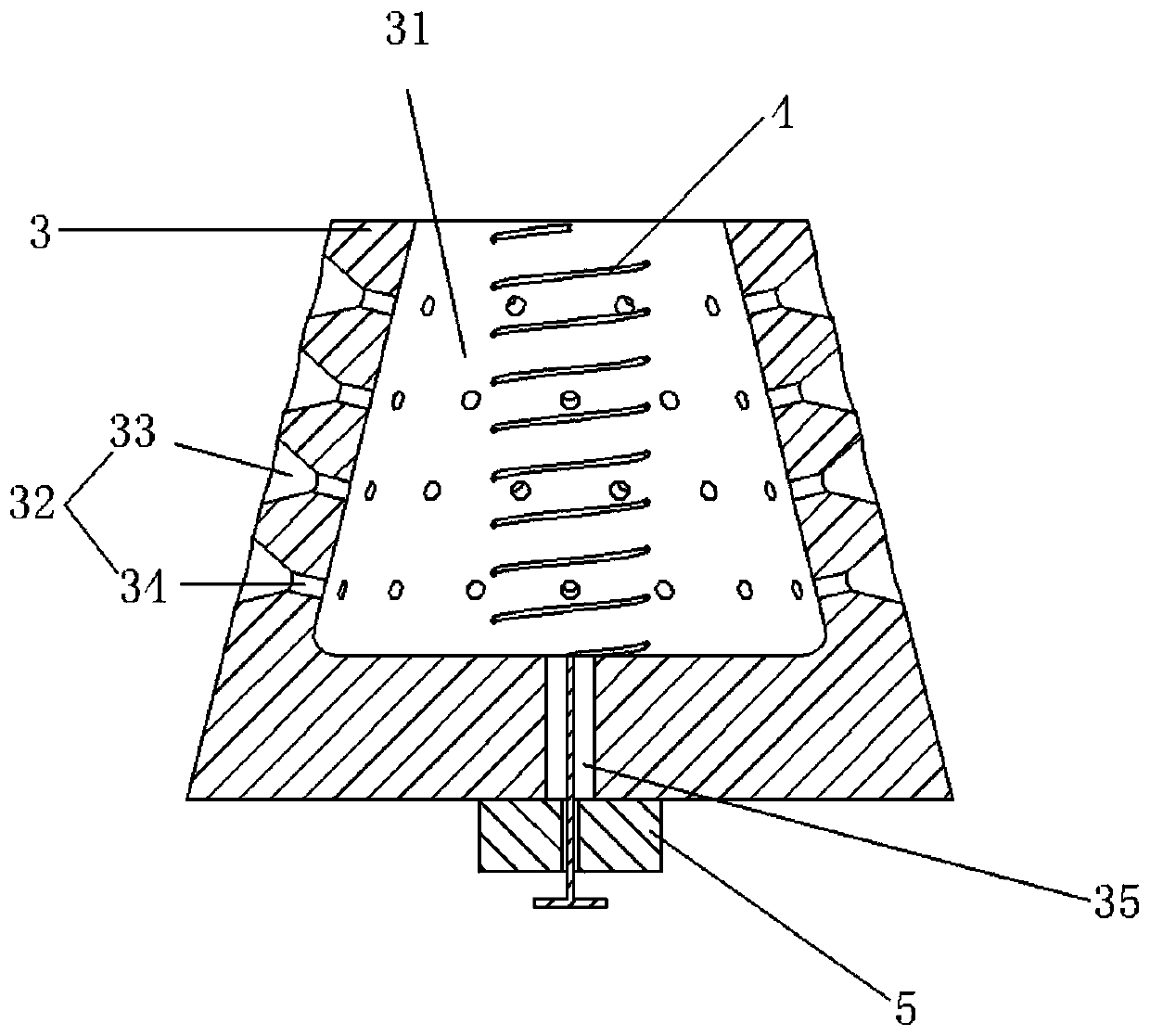

[0018] A roller-type ring die granulator, including a molding cavity, is characterized in that: the molding cavity of the granulator is placed horizontally, a rotatable bottom plate 1 is arranged at the bottom of the molding cavity, and a roller ring mold 3 and Particle collection bin 2, the roller ring mold 3 is in the shape of a circular platform, extending from the side wall of the molding cavity to the center of the molding cavity, the side wall of the roller ring mold 3 is in contact with the bottom plate 1, and the interior of the roller ring mold 3 is hollow Cavity 31, the upper end surface of the roller rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com