Material outlet adjusting apparatus of crusher

A technology of adjustment device and discharge port, applied in the field of mining equipment, can solve the problems of high manufacturing, operation and maintenance costs, insufficient adjustment and flexibility, and high labor intensity, and achieves the effects of compact structure, flexible and rapid adjustment, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

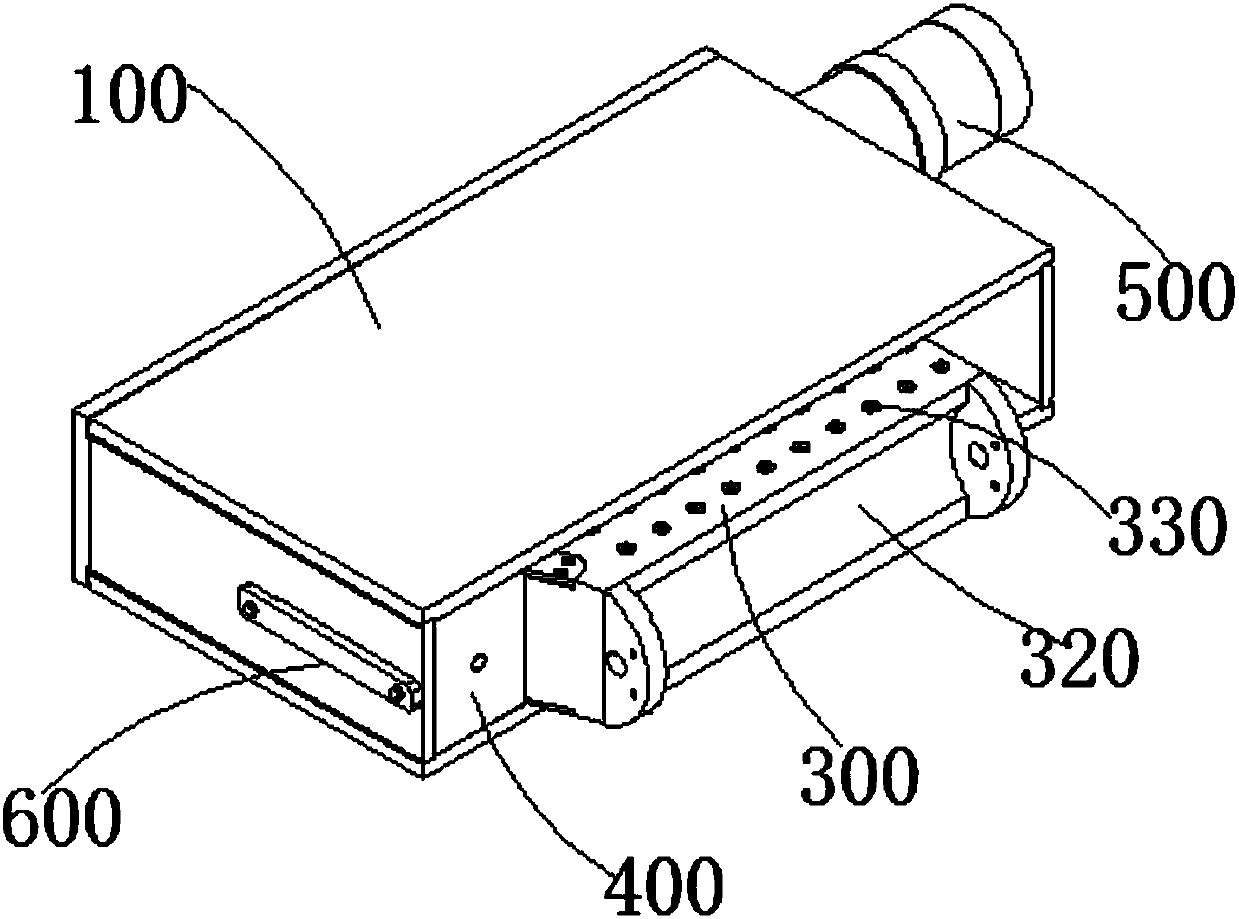

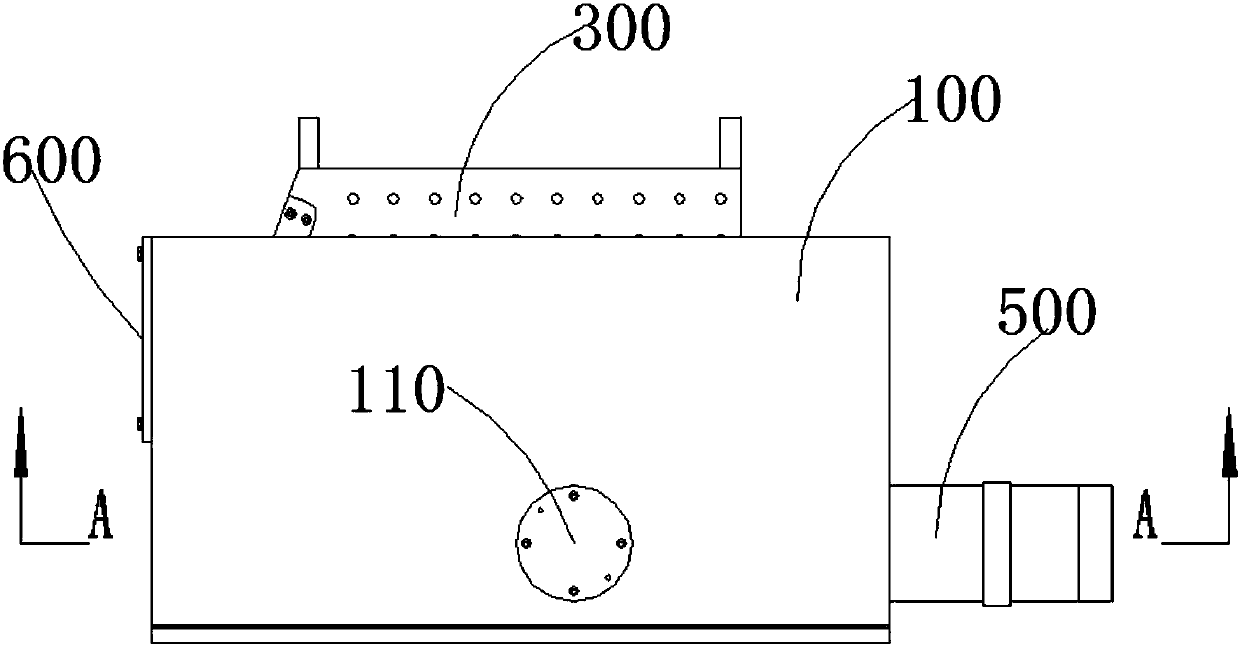

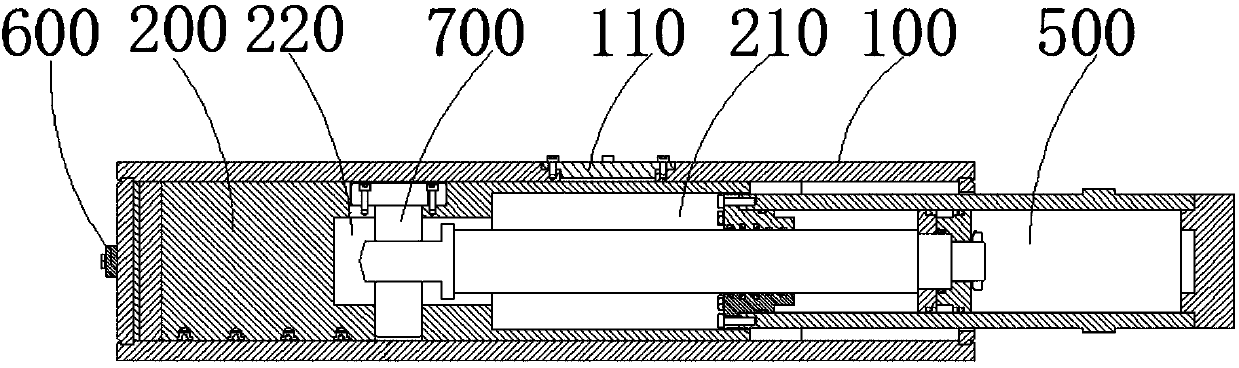

[0045] see Figure 1-5 , the present embodiment provides a crusher 800 outlet adjustment device, which includes a box 100 , a driving wedge 200 , a driven wedge 300 , a fixed wedge 400 and an oil cylinder 500 .

[0046] Wherein, the box body 100 is in the shape of a cuboid, which includes six side walls, wherein two adjacent side walls are respectively provided with avoidance holes for installing the oil cylinder 500 and telescopic holes for the expansion and contraction of the driven wedge 300 .

[0047] Both the active wedge 200 and the driven wedge 300 are slidably connected in the box body 100. The active wedge 200 is provided with an active sliding surface, and the side of the active slider away from the active sliding surface is connected to the inner wall of the box body 100. fit.

[0048]The fixed wedge 400 is fixedly connected to the inner surface of the side wall of the box body 100 away from the escape hole. The fixed wedge 400 is provided with a fixed guide surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com