Bicycle punching device

A technology of punching device and bicycle, applied in positioning device, driving device, boring/drilling and other directions, can solve the problems of inconsistent depth of product pockets, high processing cost, and large number of drill bits, etc., to achieve good fixing effect and prevent car Circle scratches, the effect of reducing working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

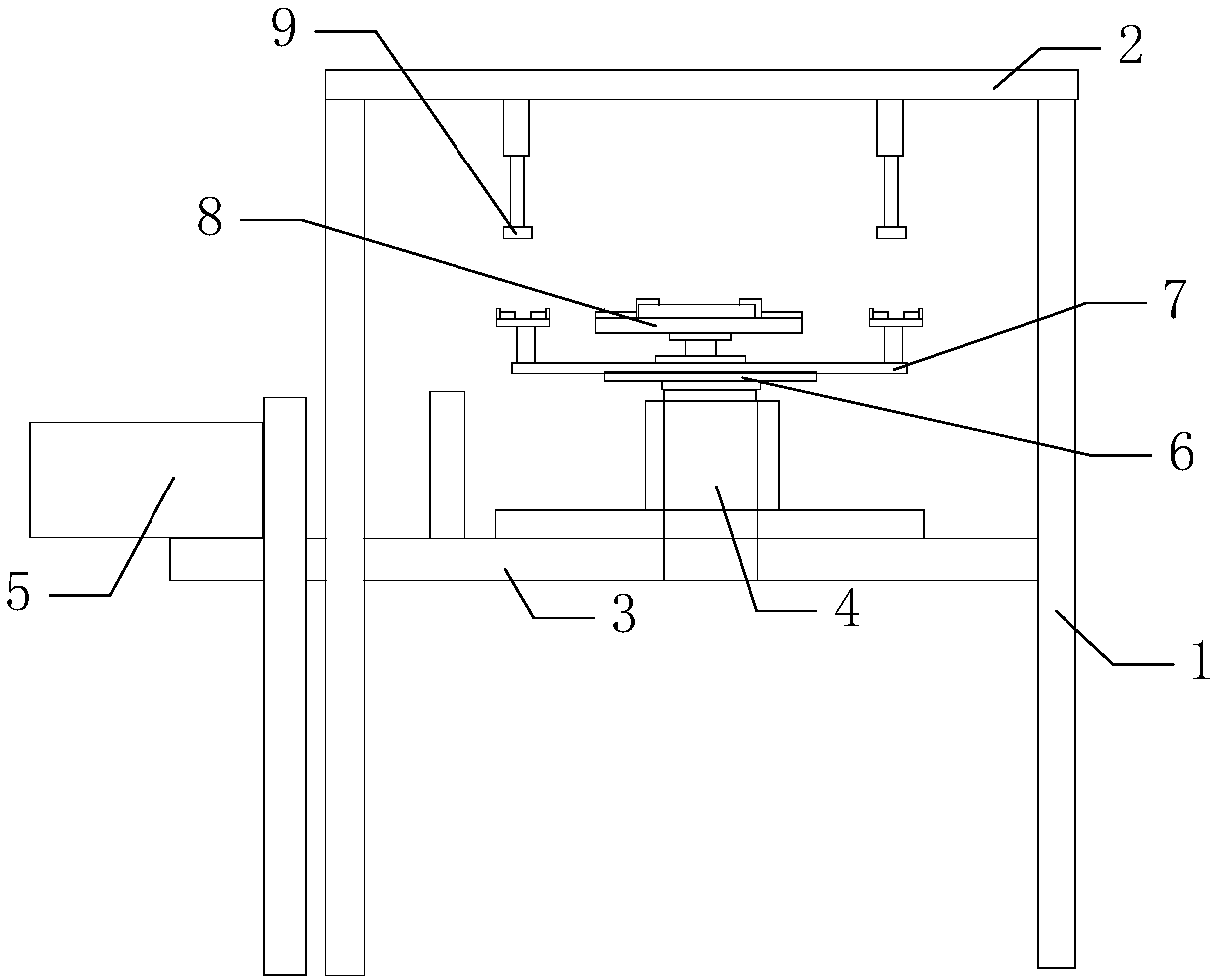

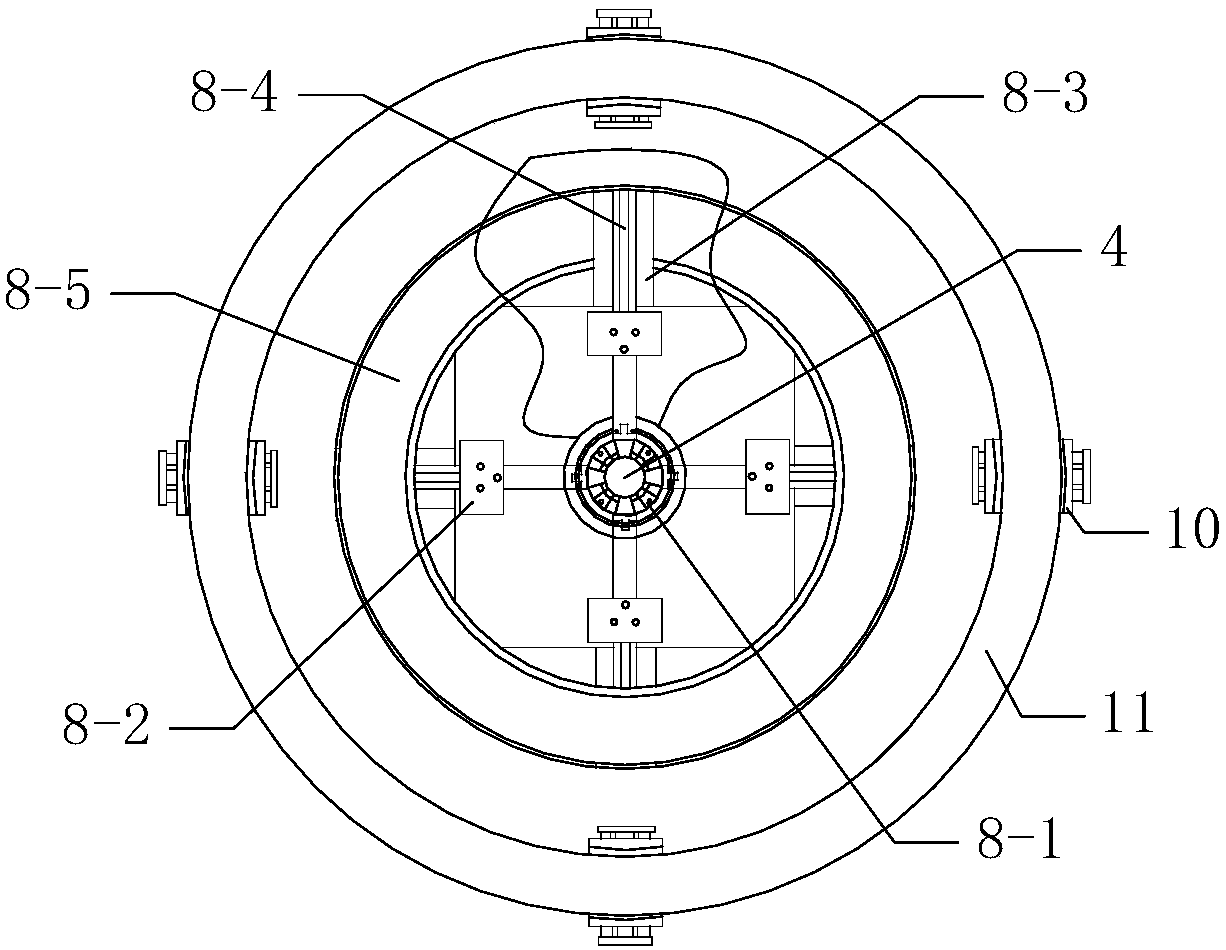

[0025] like figure 1 As shown, a bicycle punching device includes a driving device and a fixing device, the driving device includes a driving shaft 4 and a driving seat 8, and the driving seat 8 includes a rotating shaft 8-1, a moving block 8-2, a knife Disc 8-5 and drill bit 8-4, described drive shaft 4 is provided with rotating shaft 8-1, and described rotating shaft 8-1 is provided with cutterhead 8-5, and described cutterhead 8-5 A moving block 8-2 is provided, and a drill 8-4 is arranged on the moving block 8-2;

[0026] The fixing device includes a bracket 1, a fixing clip 10, a fixing disc 7 and a pressing block 9, the drive shaft 4 is installed on the bracket 1, the drive shaft 4 is also provided with a fixing disc 7, and the drive shaft 4 is provided with a fixing disc 7. A fixing clip 10 is provided on the edge of the fixing disk 7 , and a pressing block 9 is arranged above the fixing clip 10 .

[0027] The moving block 8-2 is evenly distributed on the cutter head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com