Plant polishing and waxing device

A plate and platform technology, which is applied in the field of plate polishing and waxing devices, can solve the problems of difficulty in guaranteeing processing quality, affecting product processing efficiency, and large equipment footprint, and achieves convenient operation, simple structure, and small equipment footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

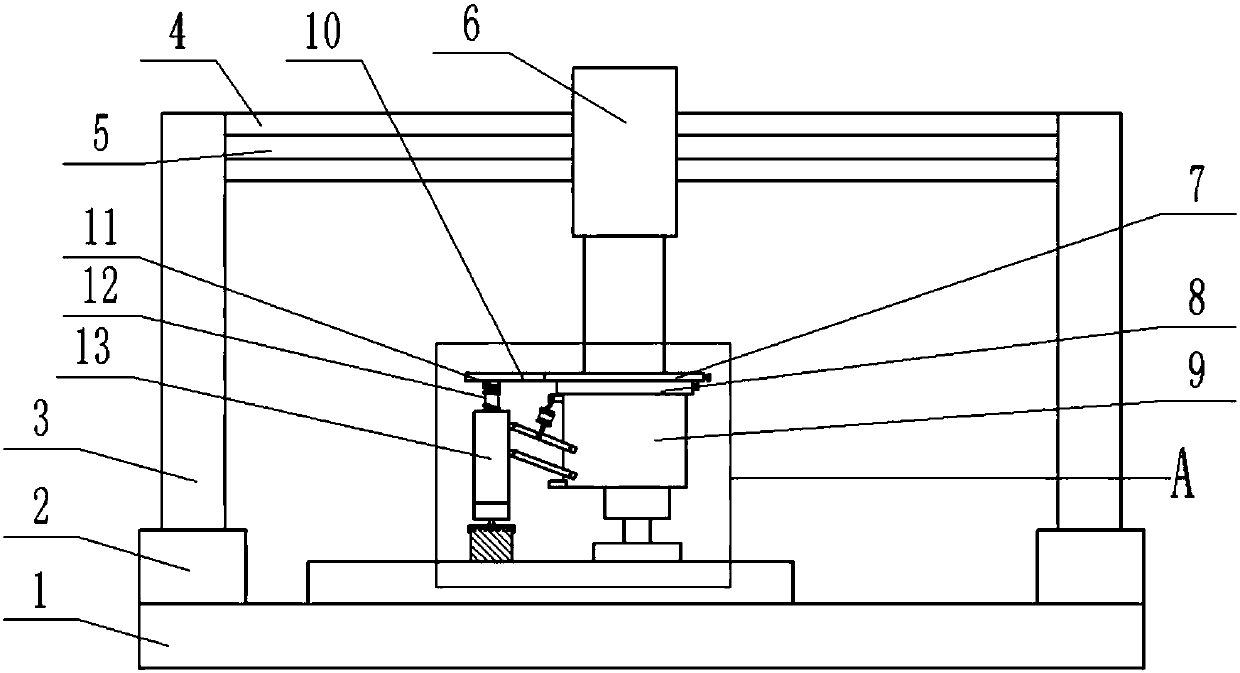

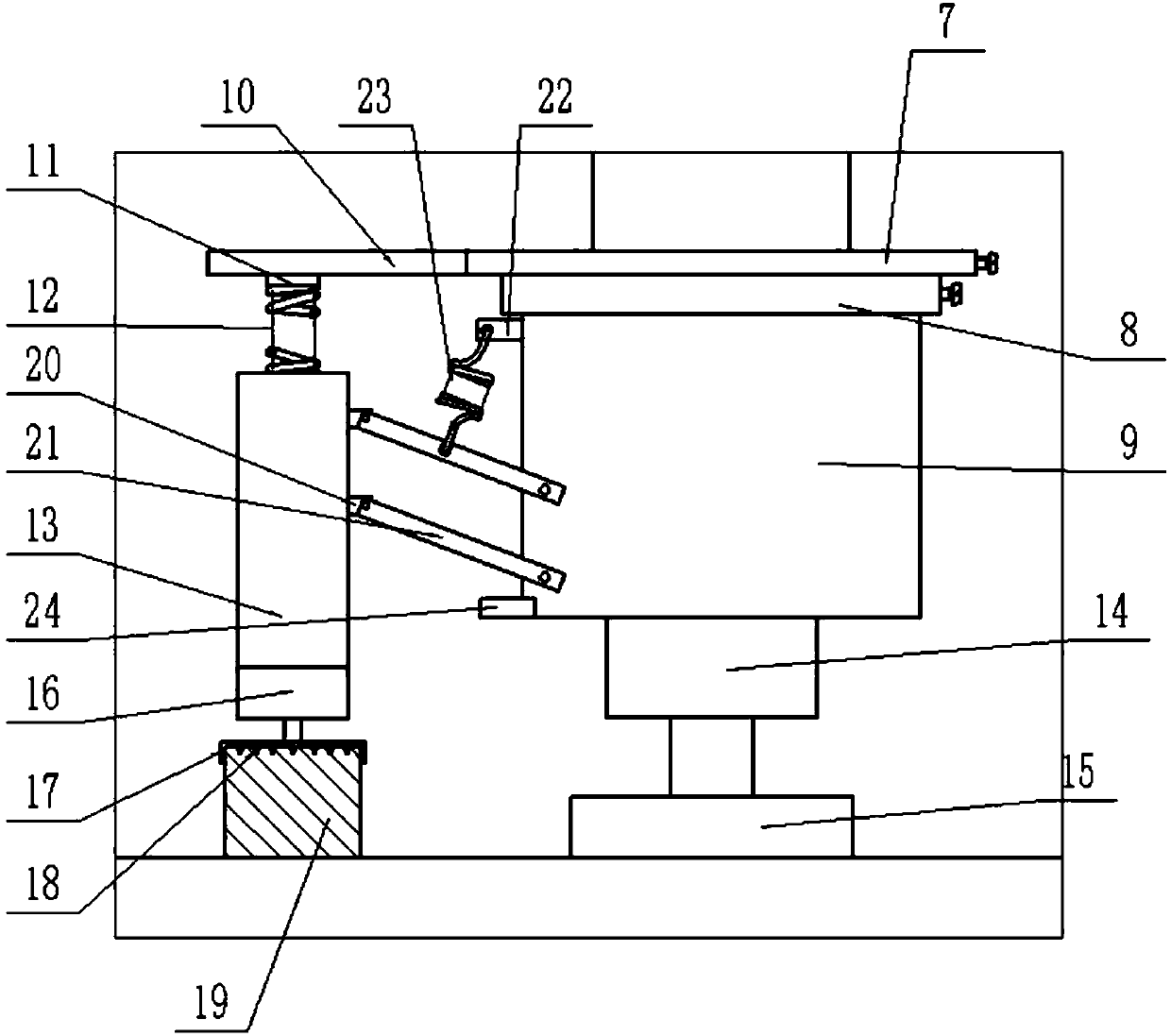

[0016] Such as figure 1 , 2 As shown, a plate polishing and waxing device includes a platform 1, the left and right sides of the platform 1 are provided with longitudinal slide rails 2, and the vertical slide rails 2 are provided with support rods 3 that slide and cooperate with them. The upper ends of the support rods 3 are formed by horizontal The connecting rod 4 is connected, and the front of the connecting rod 4 is provided with a chute 5, and the cylinder body of the electric telescopic cylinder 6 facing the platform 1 is slidably matched with the chute 5, and the lower end of the telescopic rod of the electric telescopic cylinder 6 is provided with a sleeve 8, A rotating block 9 is arranged inside the casing 8, a first motor 14 with a rotating shaft facing the platform 1 is fixed on the lower end surface of the rotating block 9, a polishing wheel 15 is arranged on the rotating shaft of the first motor 14, and a lifting rod is arranged on the left side of the rotating bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com