Integral structure of automotive plastic back door

A back door, plastic technology, applied in the superstructure, superstructure sub-assemblies, doors and other directions, can solve the problems of increasing the difficulty of assembly and management, process dispersion, long production process, etc., to improve assembly efficiency and assembly quality, The effect of reducing assembly production cost and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

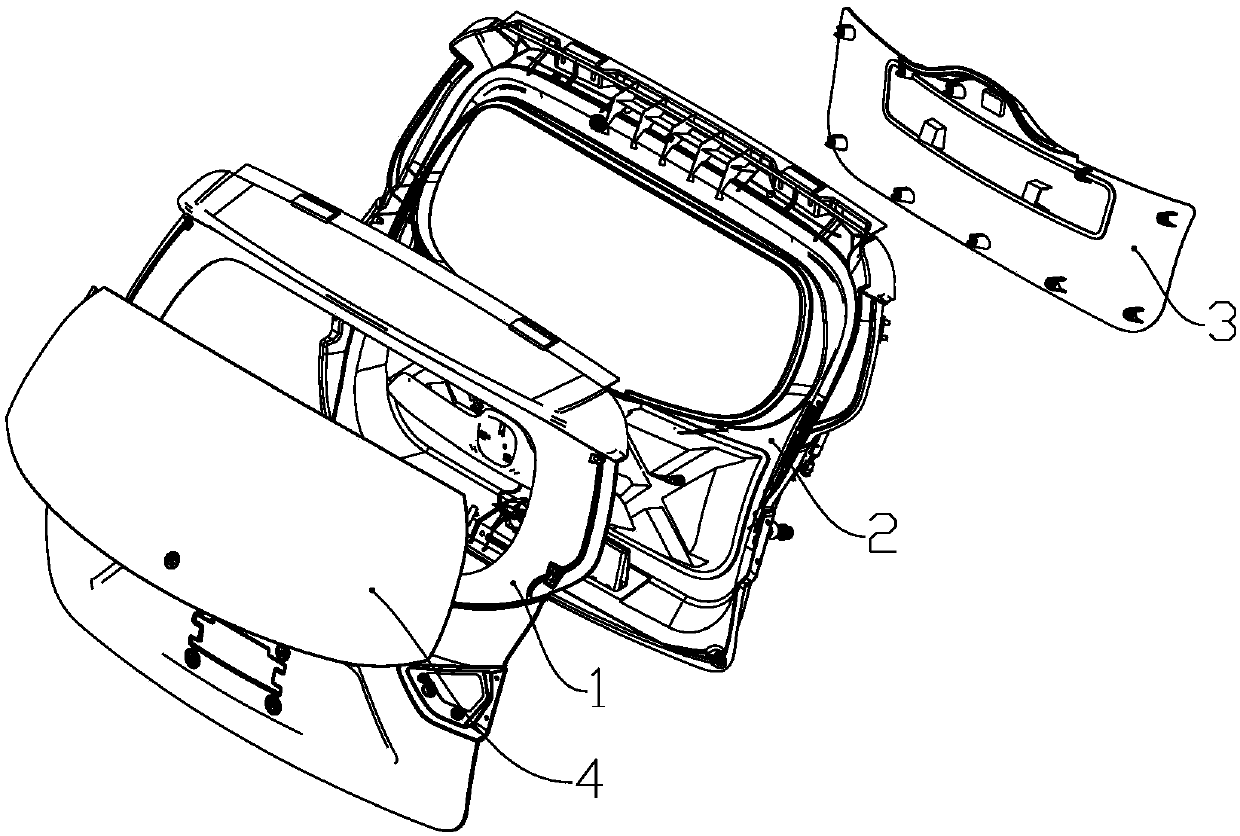

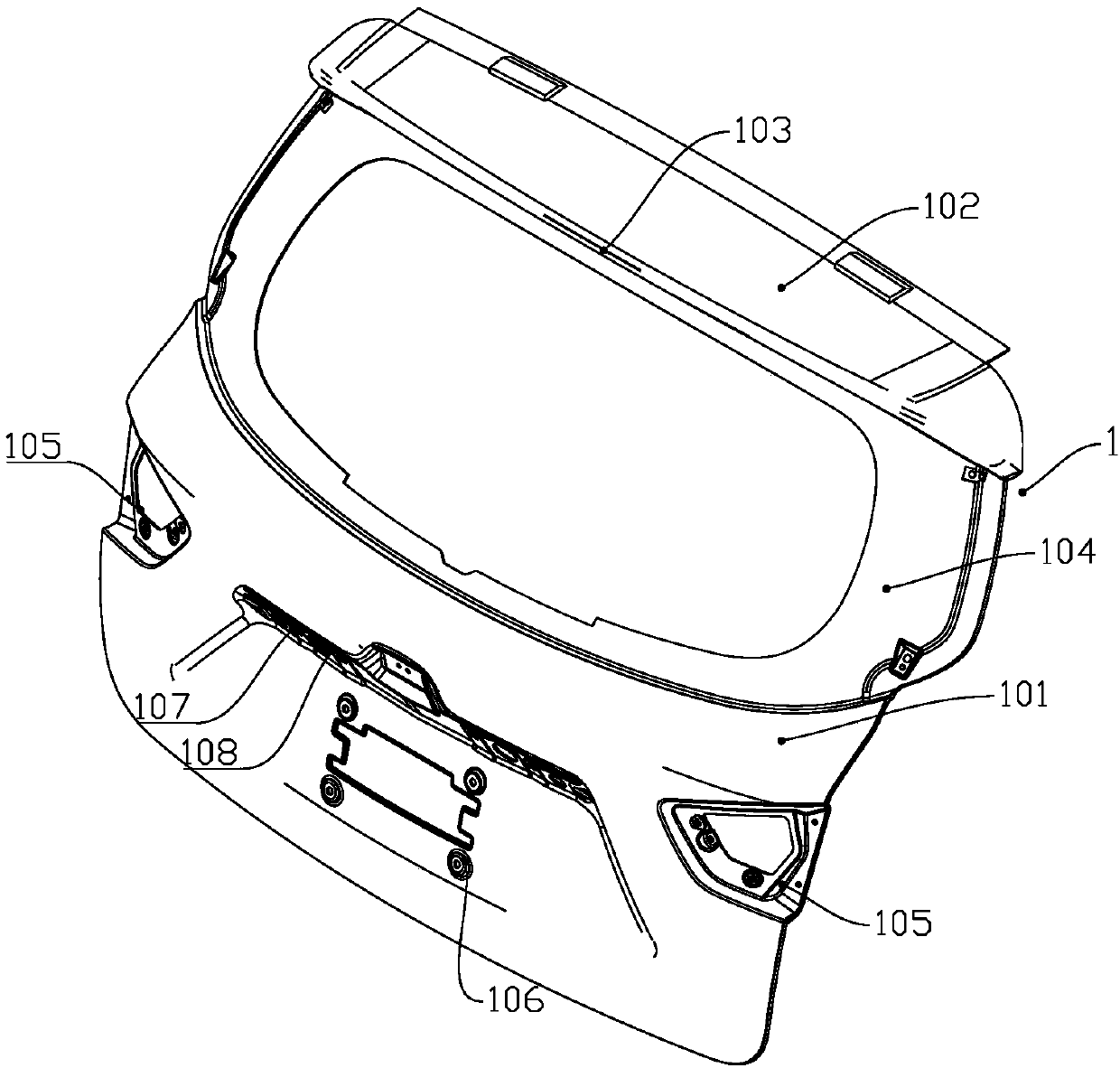

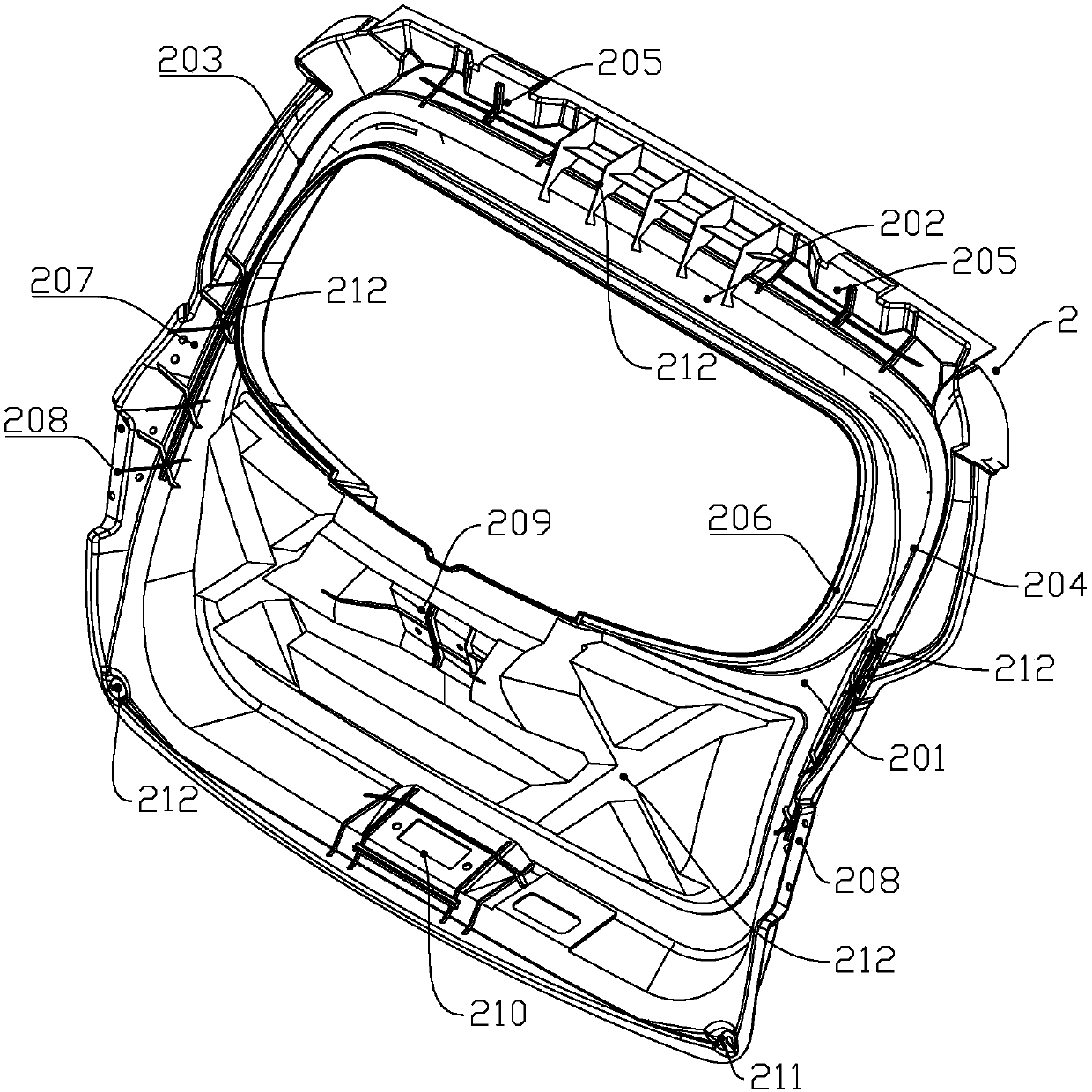

[0023] The present invention is to provide a modularized and highly integrated automobile plastic back door integrated structure, in which the automobile plastic back panel is divided into three modules: the outer panel, the inner panel and the back door decorative panel, and the outer panel The panel and inner panel are integrated with various functional parts and assembly installation structure through injection molding process. While realizing the modularization and integration of the back door itself, it is possible to assemble each assembly part outside the final assembly line, and then the module The optimized car back door assembly is directly assembled on the body, which shortens the production line and reduces the overall manufacturing cost while realizing the weight reduction of the car.

[0024] like figure 1 , in this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com