Heat sealing process of plastic packaging bag

A packaging bag and plastic technology, applied in the field of plastic bag processing, can solve the problems of weakened elastic properties of pressure springs, difficulty in exhausting air bubbles, and reduced processing efficiency of plastic bags, so as to achieve the effect of improving processing efficiency and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

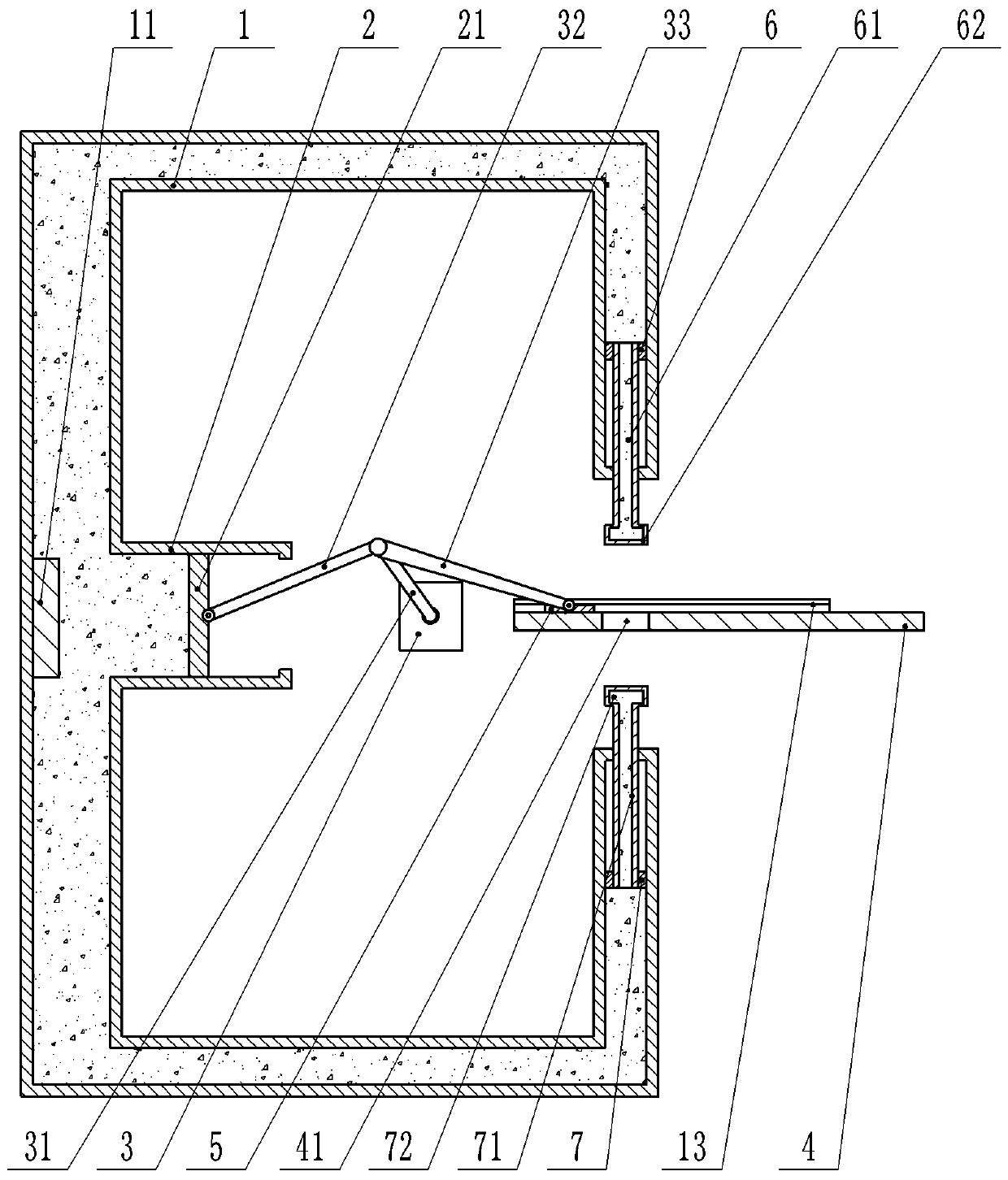

[0030] A heat-sealing process for plastic packaging bags. The heat-sealing of plastic packaging bags is performed by a heat-sealing machine. Such as figure 1As shown, the heat sealing machine includes a workbench 4, a first driven rod 32, a second driven rod 33, a hydraulic column 1, a controller, a driving rod 31 and a motor 3, and one end of the driving rod 31 is connected to the output shaft of the motor 3 end, start the motor 3, and the active lever 31 rotates thereupon. The controller is electrically connected to the motor 3, and the controller is used to control the intermittent motion of the motor 3. The controller is purchased from the market. The controller used in this embodiment is the MAM-280A standard produced by Shenzhen Plot Electronics Co., Ltd. type controller. Before using the heat sealing machine, the controller is set according to the actual production situation. The controller controls the motor 3 to rotate once and then stops for a period of time, and t...

Embodiment 2

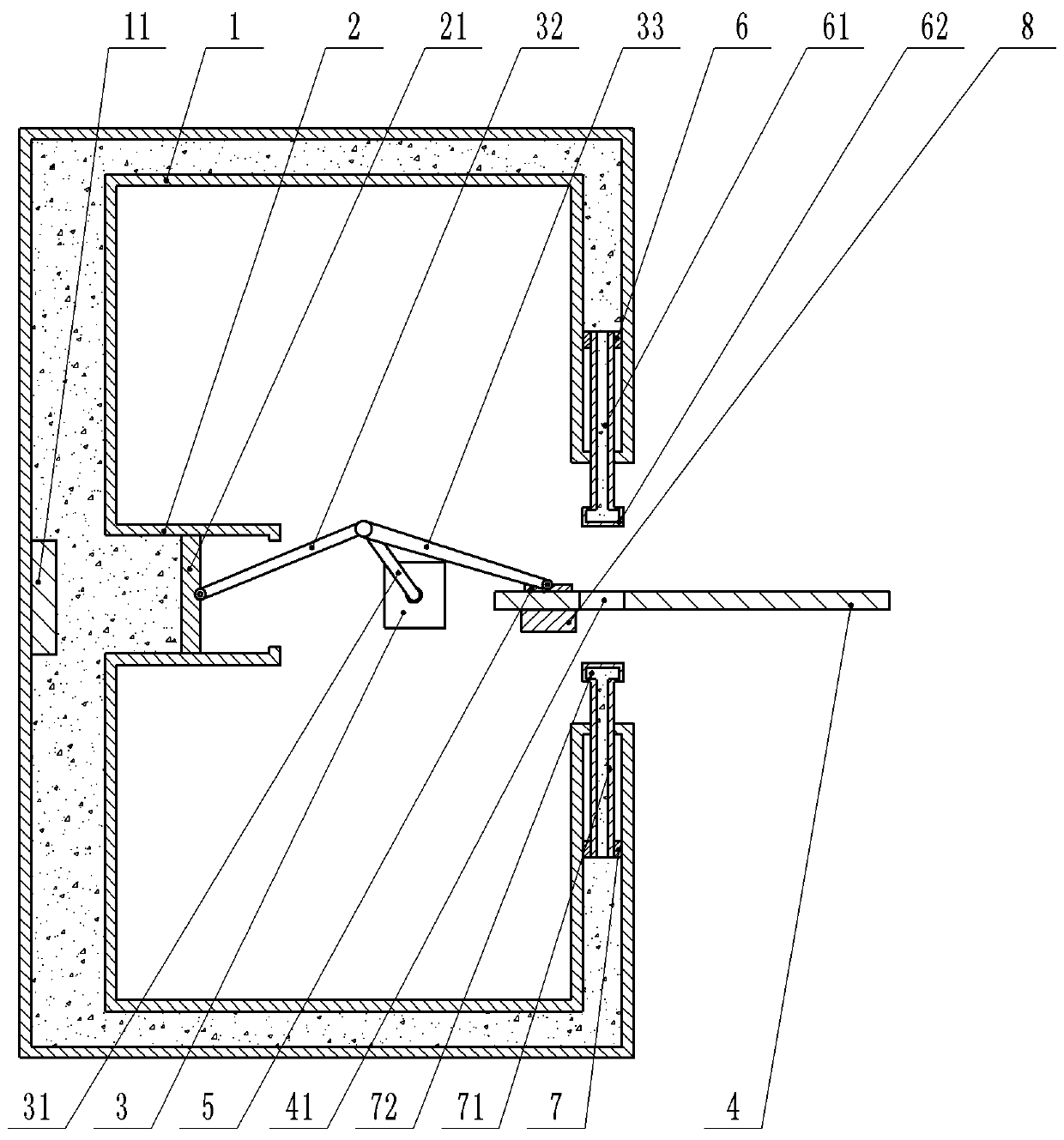

[0039] The difference between embodiment 2 and embodiment 1 is: as figure 2 As shown, guide rails are not provided on the workbench 4; the push block is designed as an iron push block, and a magnet 8 is slidably connected to the lower surface of the workbench 4, and the magnet 8 can attract each other with the push block. Under the action of the magnet 8 , the push block can be attached to the surface of the workbench 4 to prevent the push block from detaching from the workbench 4 under the action of the second follower rod 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com