Belt drying device with screening function

A belt drying and drying device technology, applied in dewatering/drying/concentrating sludge treatment, compressors with multiple evaporators, lighting and heating equipment, etc., can solve the value of sludge hardening or coking, recycling and utilization Lowering, long drying times, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

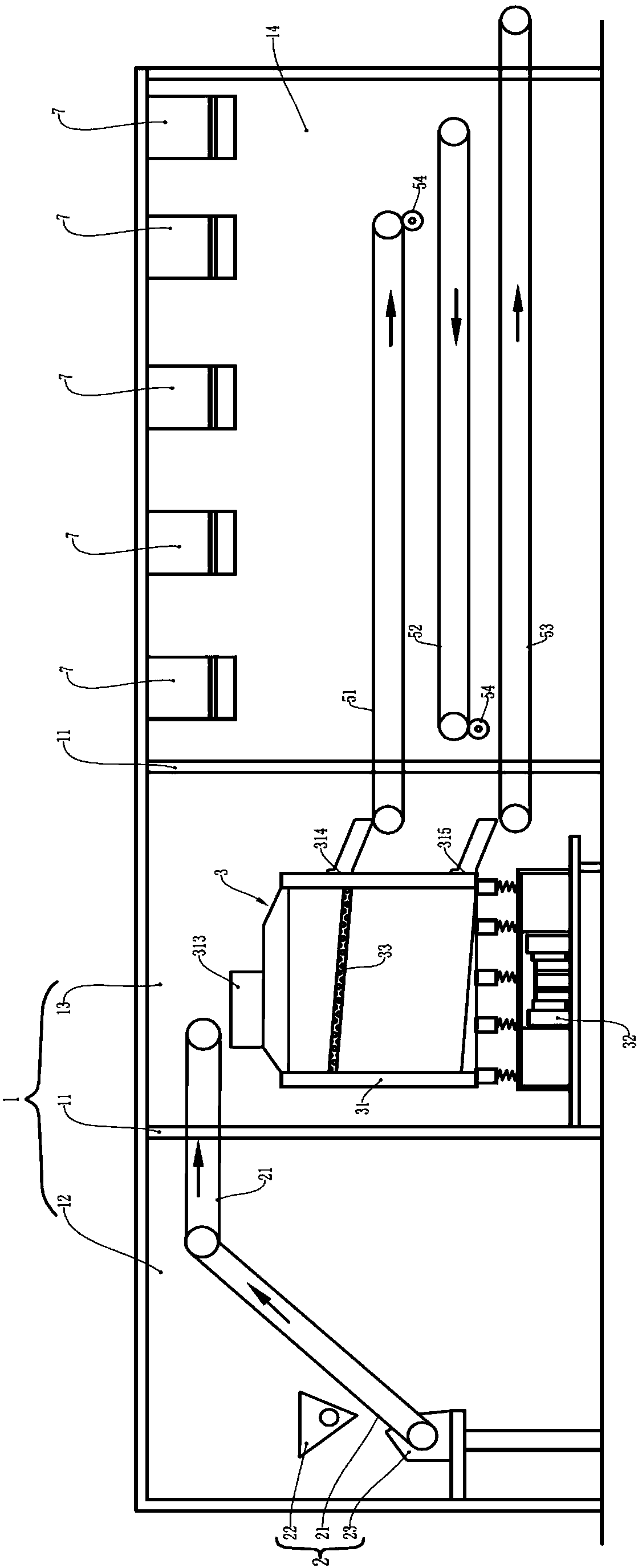

[0036] The belt drying device with screening function of the present embodiment, such as figure 1 As shown, it includes a box body 1 divided into three chambers by two vertical partitions 11, and the three chambers are a feed chamber 12, a screening chamber 13 and a drying chamber 14 from left to right;

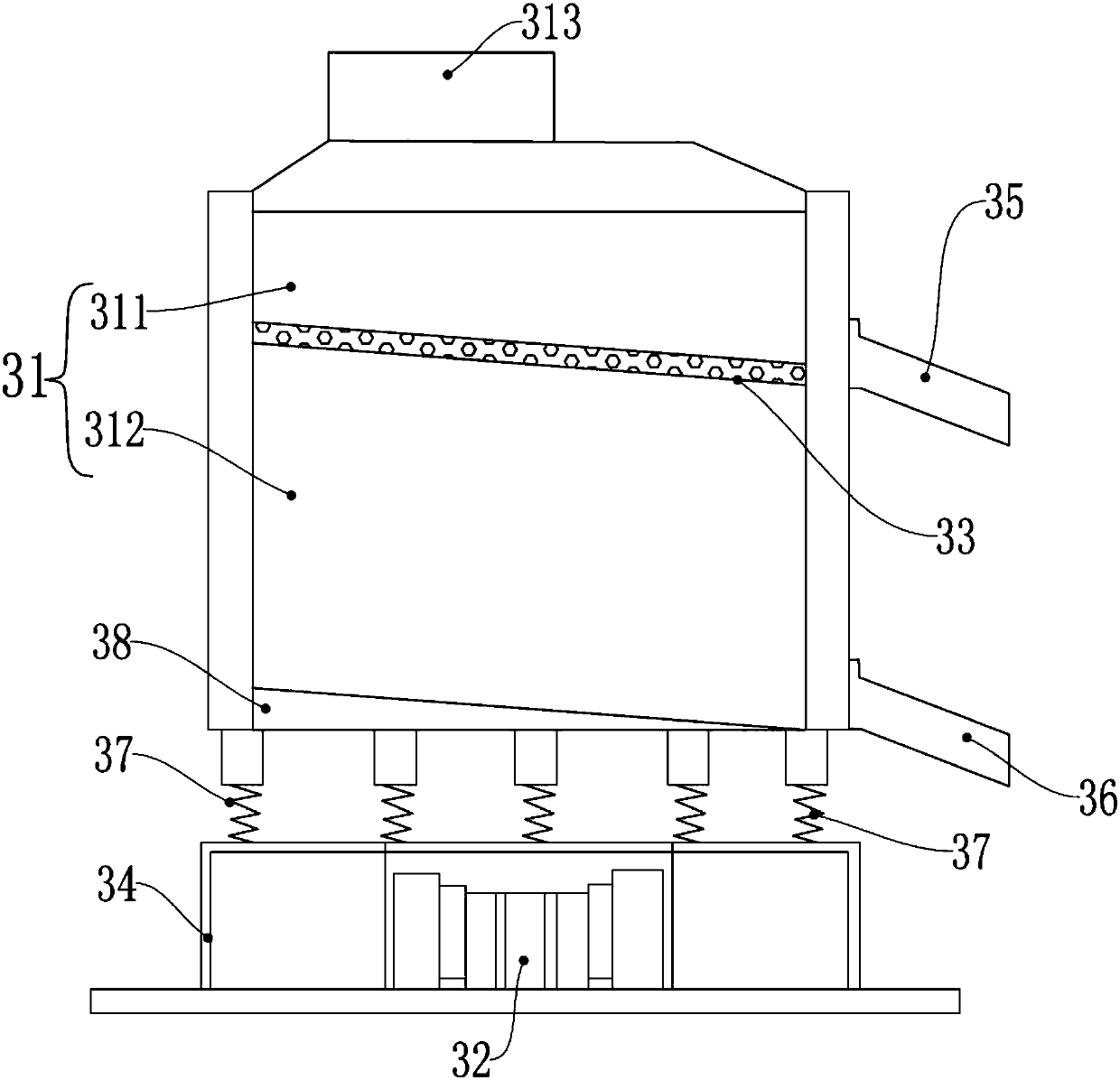

[0037] The feeding chamber 12 is equipped with a feeding mechanism 2, and the screening chamber 13 is equipped with a screening mechanism 3, and the feeding mechanism 2 includes a feeding belt 21, a feeding hopper 22 and a feeding drive motor 23. Material belt 21 is placed horizontally in described feed chamber 12, and the end of described feed belt 21 extends to described screening chamber 13, and described feed hopper 22 is arranged on the beginning of described feed belt 21; The material belt 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com