Production system of iso-octyl palmitate

A technology of isooctyl palmitate and production system, which is applied in the preparation of carboxylate, separation/purification of carboxylate, and preparation of organic compounds, etc. It can solve the problems of large equipment investment, complicated operation, and the purity of isooctyl palmitate. No high-level problems, to achieve the effect of reducing enterprise costs, reducing environmental pollution, and controllable response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

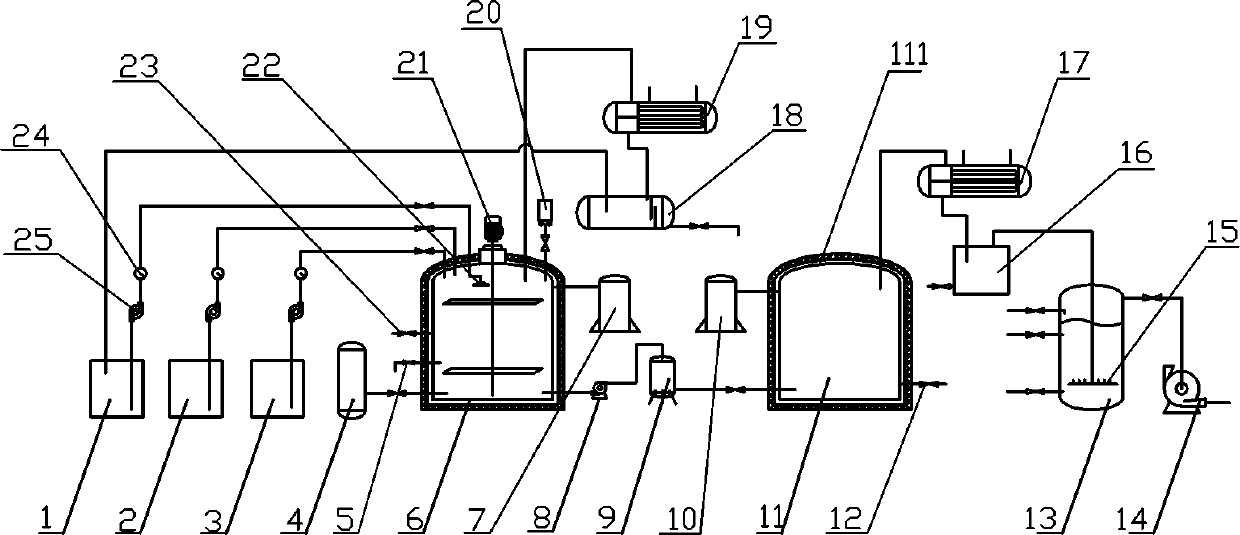

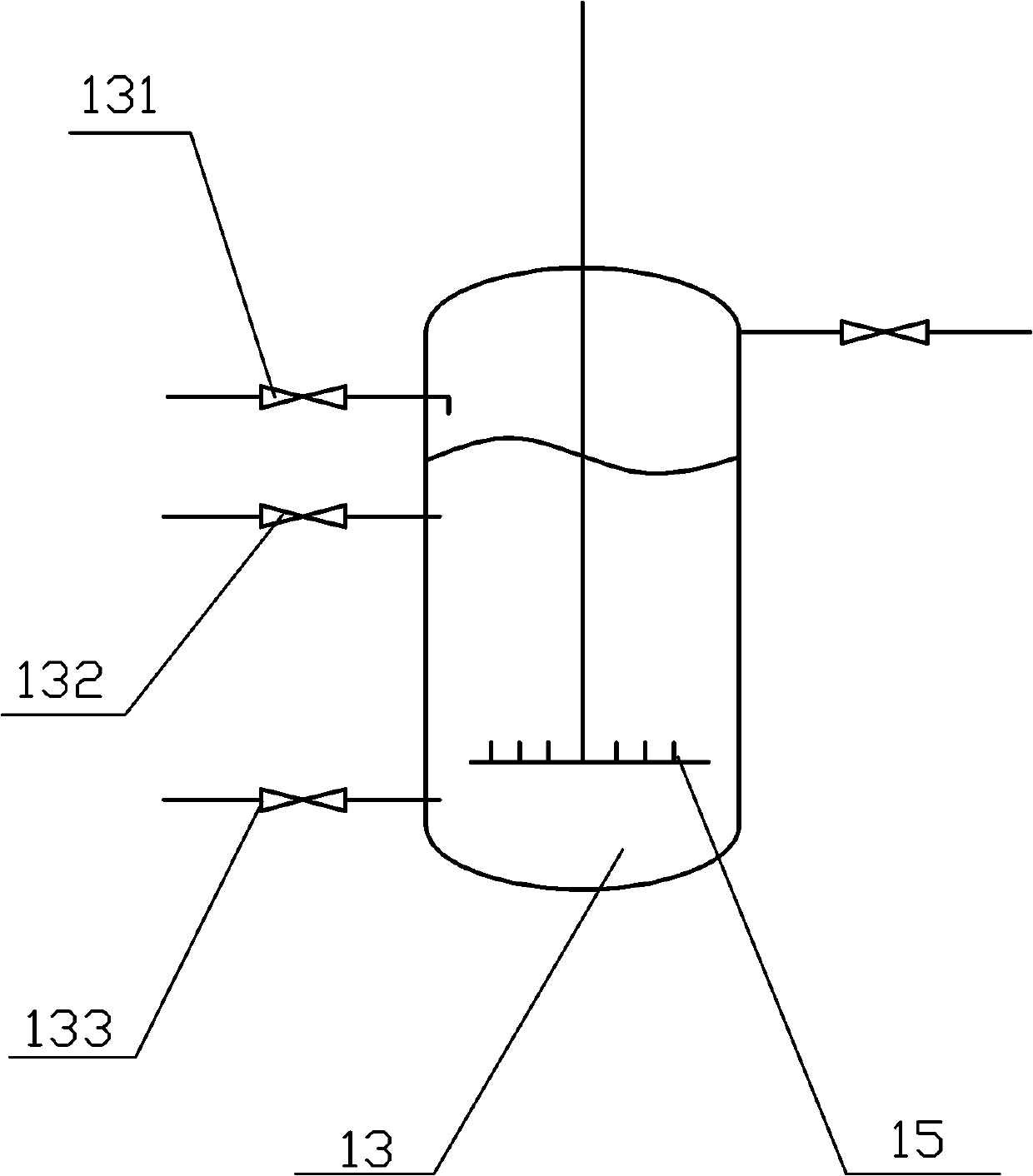

[0020] A production system of isooctyl palmitate, comprising an esterification reaction part and a purification part,

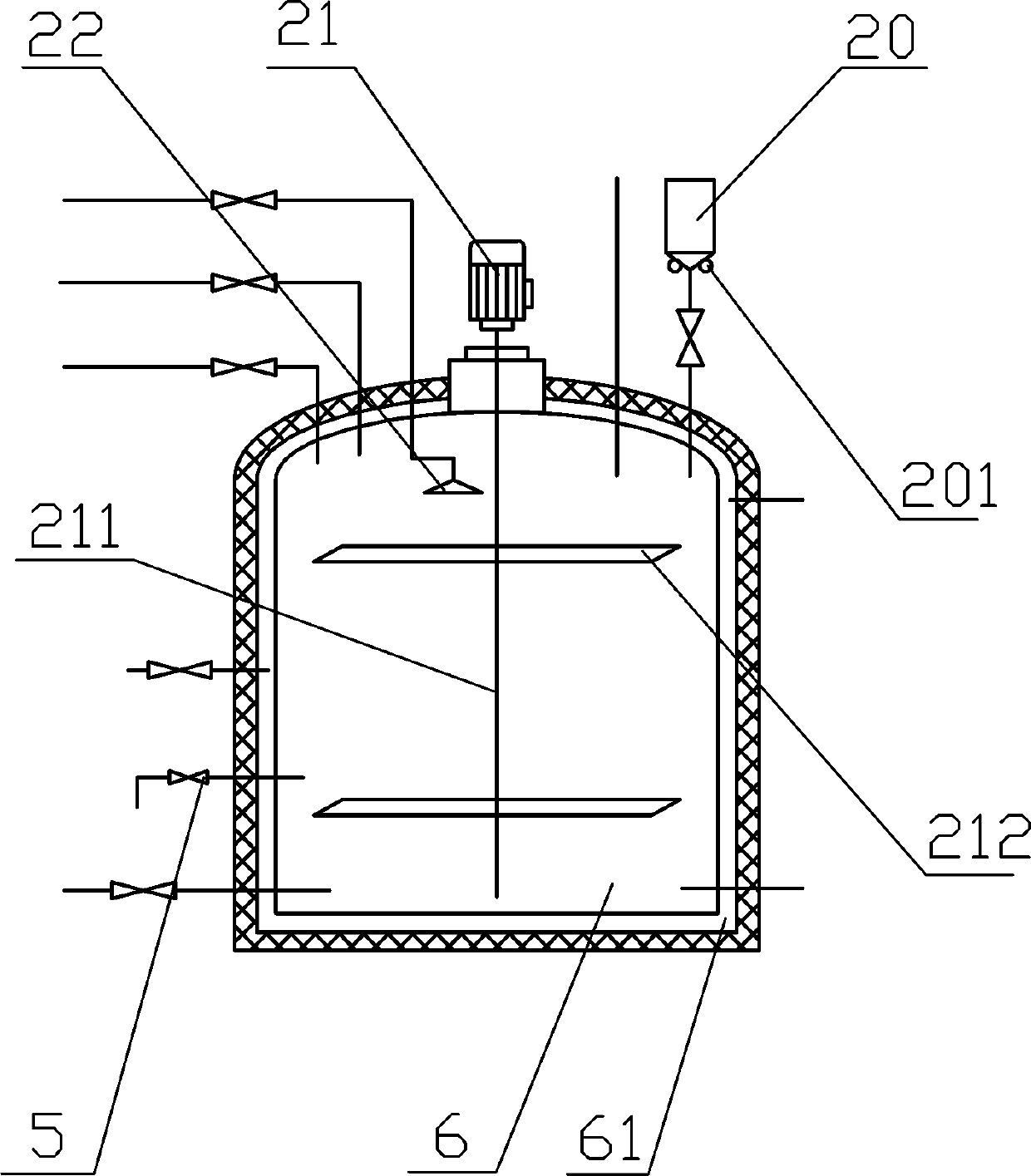

[0021] Esterification reaction part: including reaction tank 6, palmitic acid storage tank 2, isooctyl alcohol storage tank 1, cyclohexane storage tank 3, nitrogen cylinder 4, first condenser 19, oil-water separator 18, catalyst storage tank 20, Stirring device and the first steam generator 7; Palmitic acid storage tank 2, isooctyl alcohol storage tank 1 and hexanaphthene storage tank 3 are respectively connected to the reaction tank 6 top by a liquid inlet pipe, on the liquid inlet pipe is installed Metering pump 25, flow meter 24 and valve, nitrogen cylinder 4 are connected to the bottom of reaction tank 6 through pipelines, the inlet of first condenser 19 is connected to the top of reaction tank 6 through exhaust pipe, and the outlet of first condenser 19 is through outlet pipe Connected to the inlet of the oil-water separator 18, the oil outlet of the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com