A method for processing aluminum-vanadium sandwich alloy slag

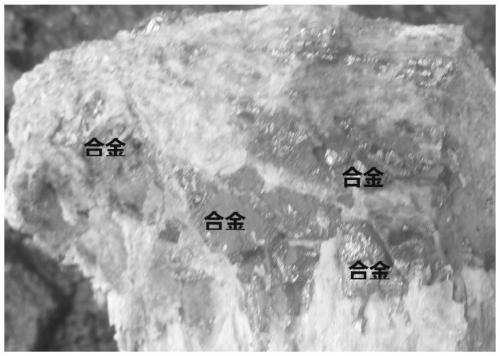

An alloy slag, aluminum vanadium technology, applied in the direction of improving process efficiency, can solve the problems of decreased alloy yield, large content, increased cost, etc., and achieve the effects of reducing shrinkage cavities, slowing down temperature drop, and excellent refractory performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

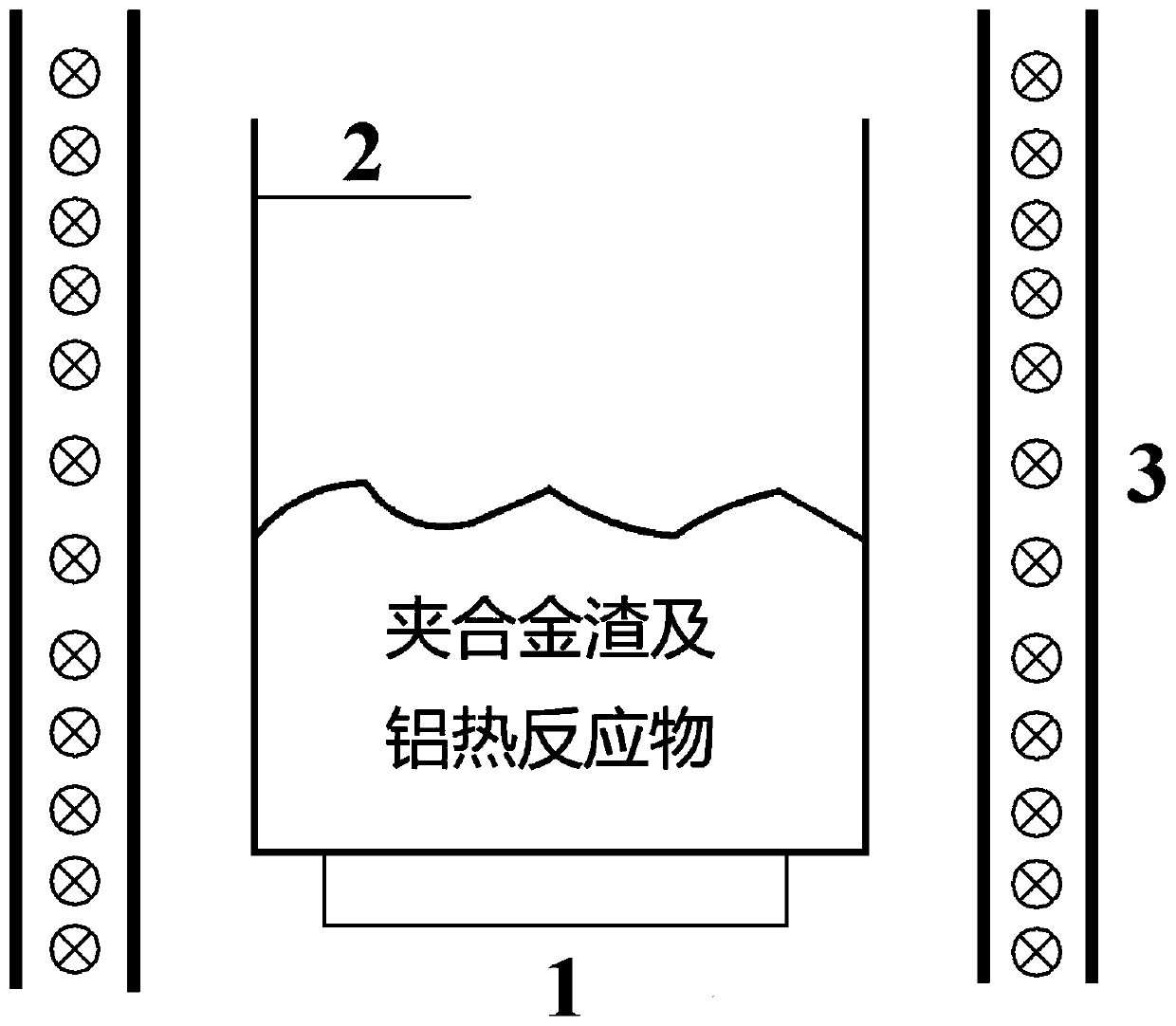

[0064] In the present invention, conventional preparation devices in the field can be used to process aluminum-vanadium sandwich alloy slag, that is, the operation of slag-liquid separation-ultrasonic refining. Such as figure 2 As shown, the structure and operation of the ultrasonic refining reaction tank adopted when a specific embodiment of the present invention handles aluminum-vanadium alloy slag can be: the vanadium-aluminum alloy slag and thermite reactant (that is, the raw material for preparing the alloy slag) ) is placed in the reaction pool 2; the heating source 3 is distributed on both sides or around the reaction pool 2, and the reaction pool is heated and heated when it is powered on; the ultrasonic generator 1 is placed at the bottom or side of the reaction pool 2, and high-frequency waves are provided Vibrate and physically stir the reaction pool 2 frequently; wherein, when the ultrasonic generating device 1 is located at the side of the reaction pool 2, the po...

Embodiment 1

[0067] A kind of ultrasonic refining processing folder alloy slag reclaims the method for 55 vanadium aluminum alloy, carries out according to the following process steps:

[0068] (1) Mechanically crushing the inclusion alloy slag produced by the preparation of 55 vanadium aluminum alloy to obtain an inclusion alloy slag powder with a particle size of 180 μm;

[0069] (2) According to the mass ratio of 3:2, mix the alloy slag powder obtained in step (1) with the thermite reactant in the reaction tank; in terms of mole percentage, the thermite reactant contains 11.87mol% V 2 o 5 , 84.63mol% Al and 3.50mol% CaF 2 ; Heating to 1000°C and igniting by resistance heating, so that aluminum and vanadium pentoxide undergo aluminothermic reduction reaction;

[0070] (3) After the reduction reaction described in step (2) is carried out for 8 minutes, the bottom of the reaction tank is subjected to ultrasonic refining treatment, the ultrasonic refining power is 1300W, and the time is ...

Embodiment 2

[0075] A kind of ultrasonic refining treatment folder alloy slag reclaims the method for 65 vanadium aluminum alloy, carries out according to the following process steps:

[0076] (1) Mechanically crushing the inclusion alloy slag produced by preparing 65 vanadium aluminum alloy to obtain an inclusion alloy slag powder with a particle size of 180 μm;

[0077] (2) According to the mass ratio of 3:2, the mixed alloy slag powder obtained in step (1) is mixed with the thermite reactant in the reaction tank; in terms of mole percentage, the thermite reactant contains 12.38mol% V 2 o 5 , 83.77mol% Al and 3.85mol% CaF 2 ; Heating to 900°C and igniting by resistance heating, so that aluminum and vanadium pentoxide undergo aluminothermic reduction reaction;

[0078] (3) After the reduction reaction described in step (2) is carried out for 10 minutes, the bottom of the reaction tank is subjected to ultrasonic refining treatment, the ultrasonic refining power is 1200W, and the time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com