Construction method of heat insulation and preservation gypsum partition wall

A heat insulation and construction method technology, applied in the direction of insulation, walls, building components, etc., can solve the problems of uneven spray coating on the wall surface of the partition wall, affect the overall structural strength of the partition wall, and affect the construction quality, so as to improve the construction quality , Reduce construction cost and improve construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

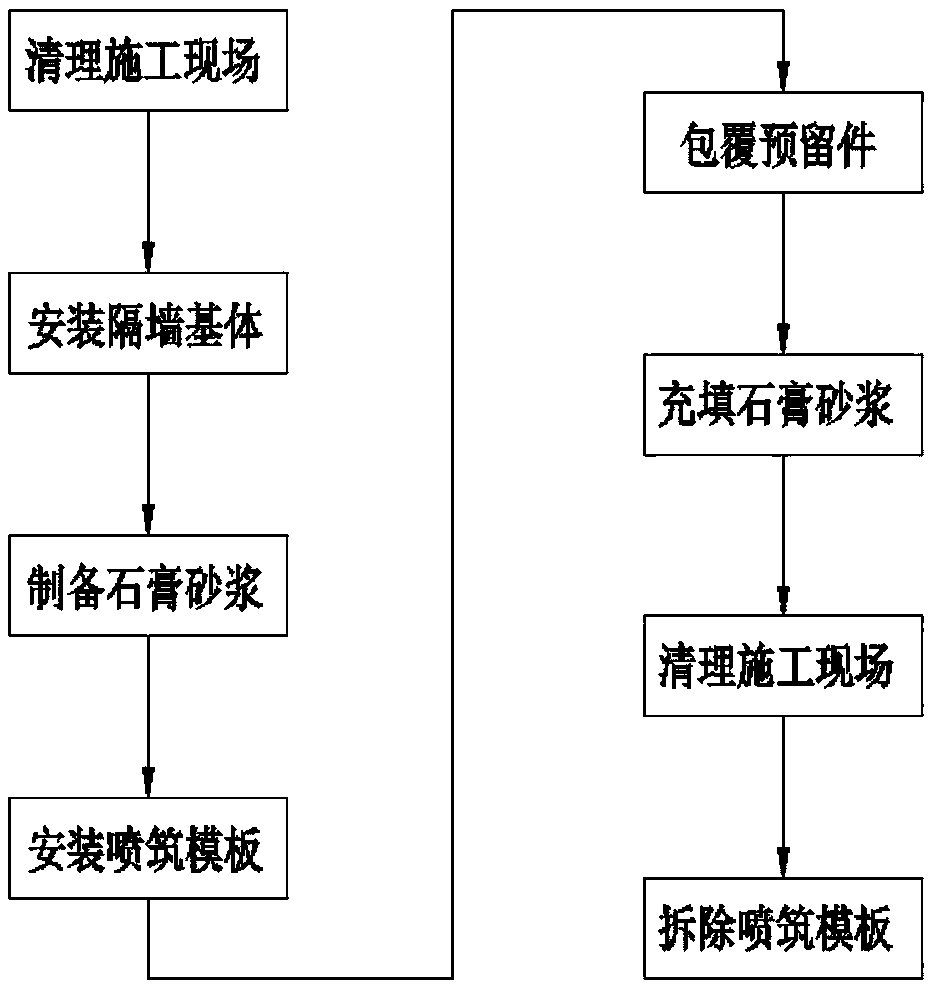

[0044] The invention provides a construction method for heat-insulating and heat-insulating gypsum partition walls, such as figure 1 shown, including the following steps:

[0045] Step 1: Remove debris, oil stains, dust, scale and residual cement on the construction site to keep the construction site ground dry and flat; further, the drawn construction drawings should comprehensively consider floor height, lap joints, boards, etc. Seam position, pipe box position, yin and yang angle, door and window openings and other factors, and the installation dimensions, door and window opening positions, line pipe direction, embedded parts position and node methods are clearly marked on the construction drawings, so as to improve the construction quality of the partition wall Foundation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com