Self-compensation type free up-down pitching coupling mechanism

A technology of ups and downs, pitching and coupling mechanisms, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of difficult longitudinal short-period motion response characteristics, inability to effectively simulate linear displacement motion, etc., and achieve high repeatability, The effect of short cycle and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

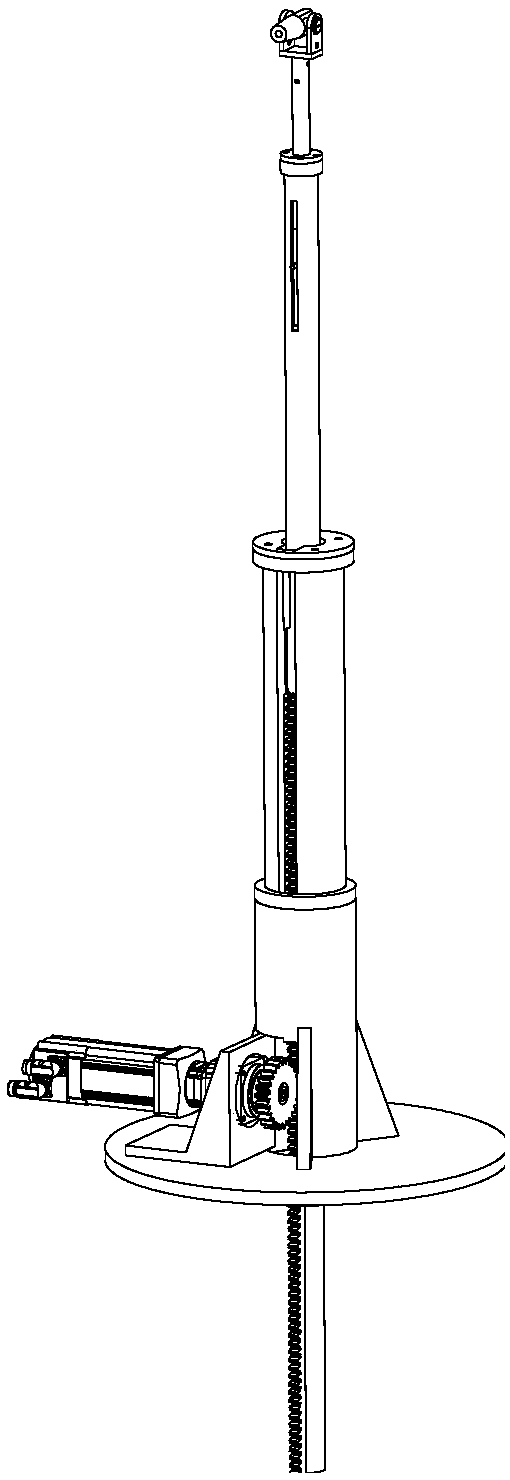

[0018] A self-compensating free-floating-pitching coupling mechanism of the present invention is used for flight simulation tests, including a free-floating pitching mechanism and a forced sinking-floating mechanism;

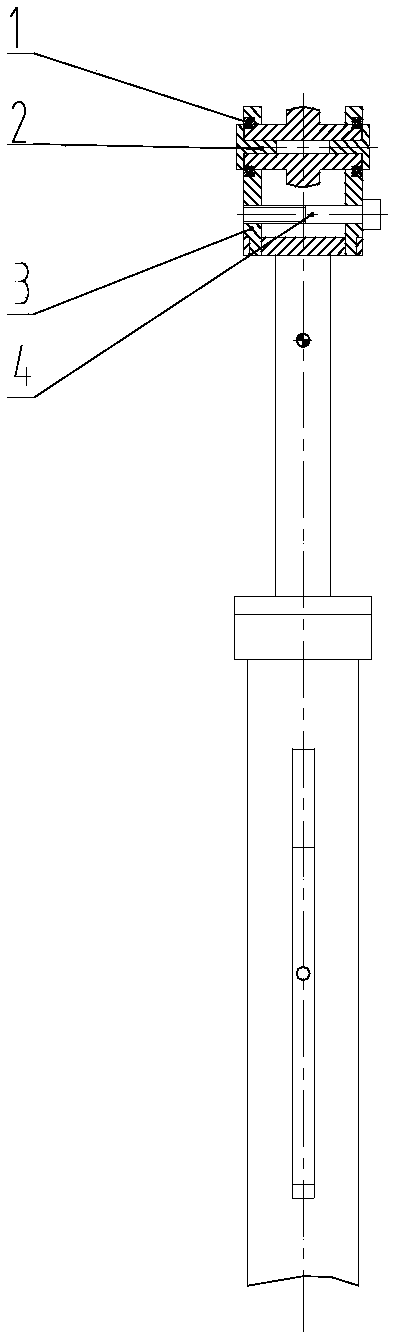

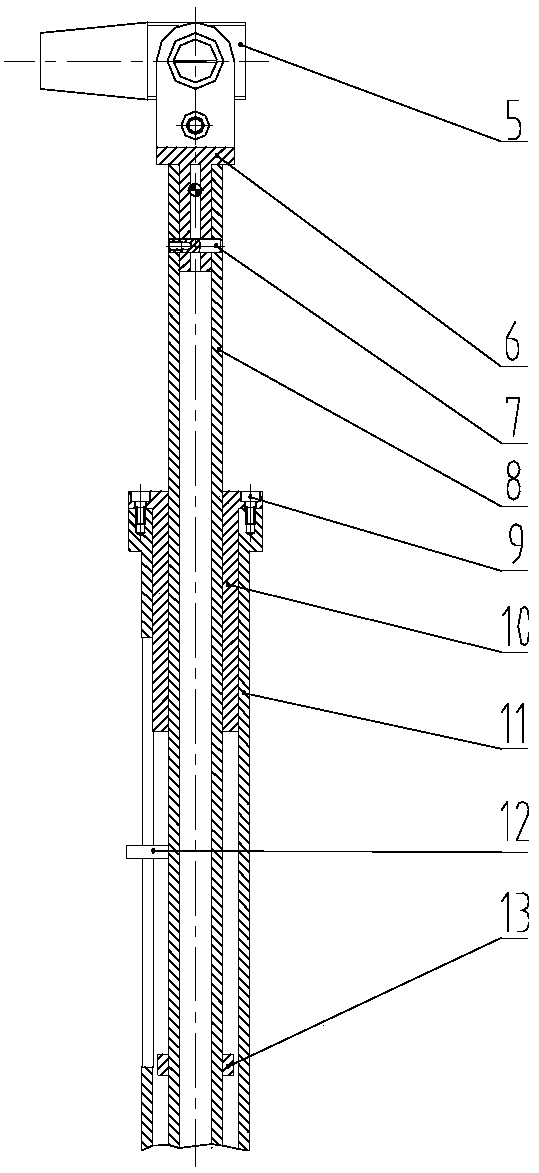

[0019] Such as figure 2 , image 3 As shown, the free-floating pitching mechanism consists of a pitching support frame 3, a pitching shaft 5, a low-damping bearing 1, a set screw 2, a pitching angle limit baffle 4, a free-floating joint 6, a pin 7, a free-floating shaft 8, and an inner hexagon Screw 9, flange-type linear bearing 10, mechanical limit baffle 13, high-precision displacement sensor 12; the top of the free-floating pitch mechanism is connected to the aircraft model through the pitch axis 5, and a low-damping bearing 1 is installed on the top of the inner hole of the pitch suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com