Screw back-up bearing wear life calculating method

A support bearing and wear life technology, which is applied in the field of screw support bearing wear life calculation, can solve the problems of inaccurate calculation of ball screw bearing wear life, etc., and achieve the effects of short research cycle, reduced research and development cycle, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

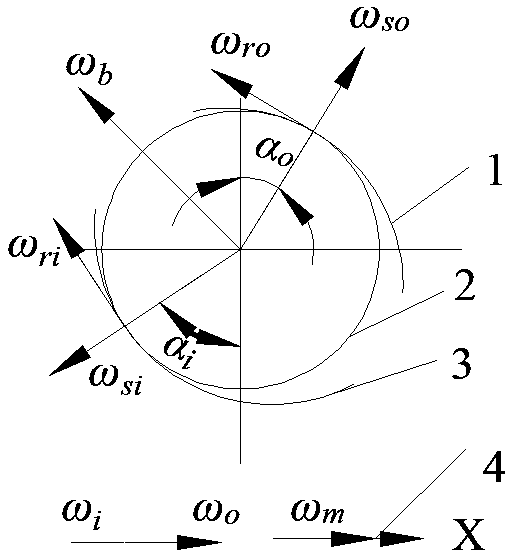

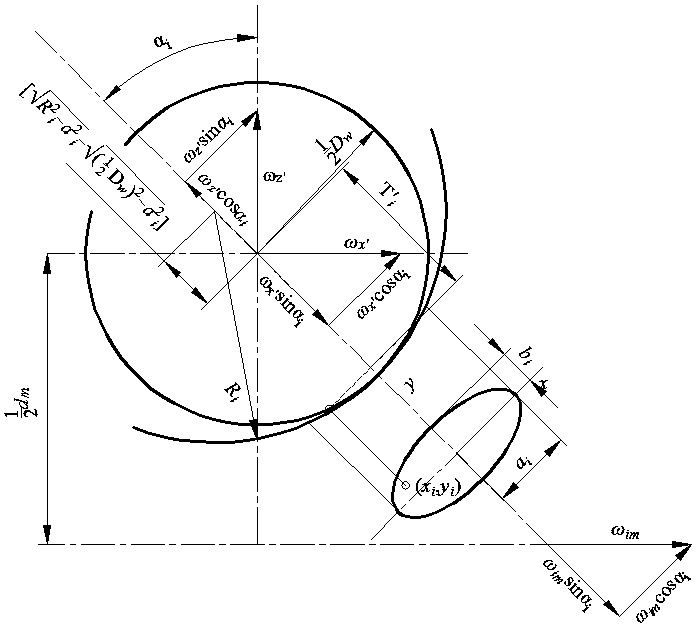

[0038] As shown in the figure, a method for calculating the wear life of a screw support bearing includes the following steps:

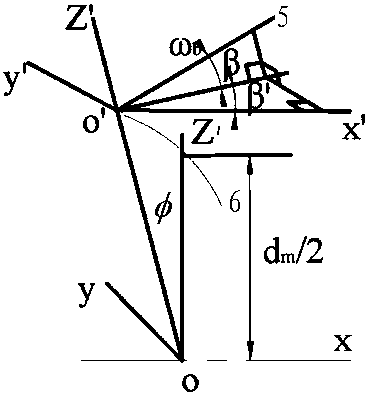

[0039] Step 1. When the bearing is in the standard coordinate system {o; x, y, z}, the rotational angular velocities of the inner ring, outer ring, cage and steel ball are respectively ω i , ω o , ω m and ω b , then project the rotation velocity of the steel ball to the coordinate axis in the coordinate system {o'; x', y', z'} to get three components ω x' , ω y' and ω z' :

[0040] ω x' = ω b cosβcosβ' (1)

[0041] ω y' = ω b cosβsinβ' (2)

[0042] ω z' = ω b sinβ (3)

[0043] The coordinate origin of the coordinate system {o'; x', y', z'} is located at the center of the steel ball, the x' axis is parallel to the x axis, and the z' axis is radially outward. The coordinate system is based on the revolution of the steel ball The speed rotates around the x-axis, β is the angle between the rotation axis of the steel ball and the x'o'y' pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com