Special high-speed steel combination roll for cold-rolling high-strength automobile sheet and manufacturing method thereof

A manufacturing method and high-speed steel technology, applied in the direction of rolls, manufacturing tools, metal rolling, etc., can solve the problems of excessive thickness of decarburized layer, micro cracks, etc., reduce wear, increase service life, and reduce manufacturing and use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

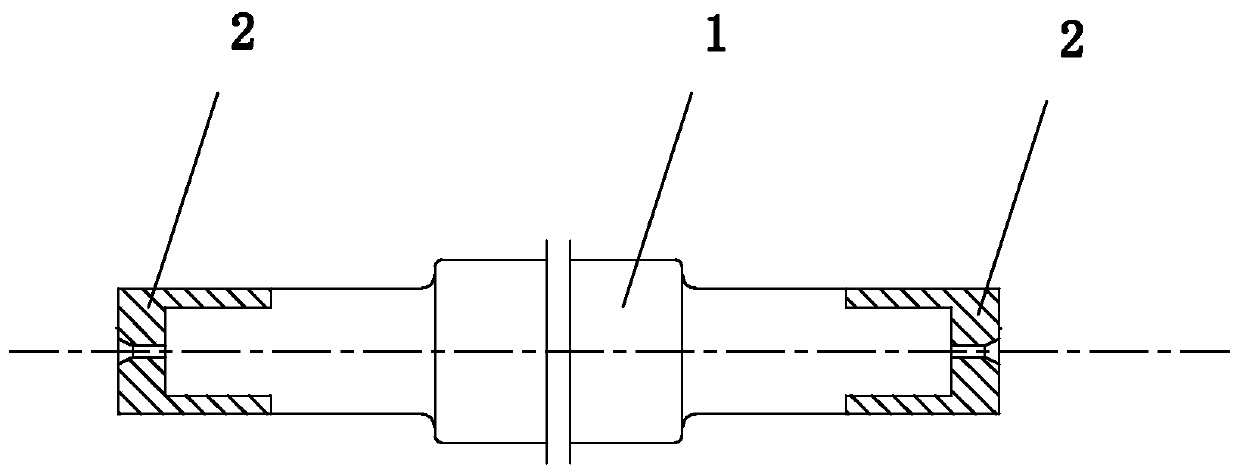

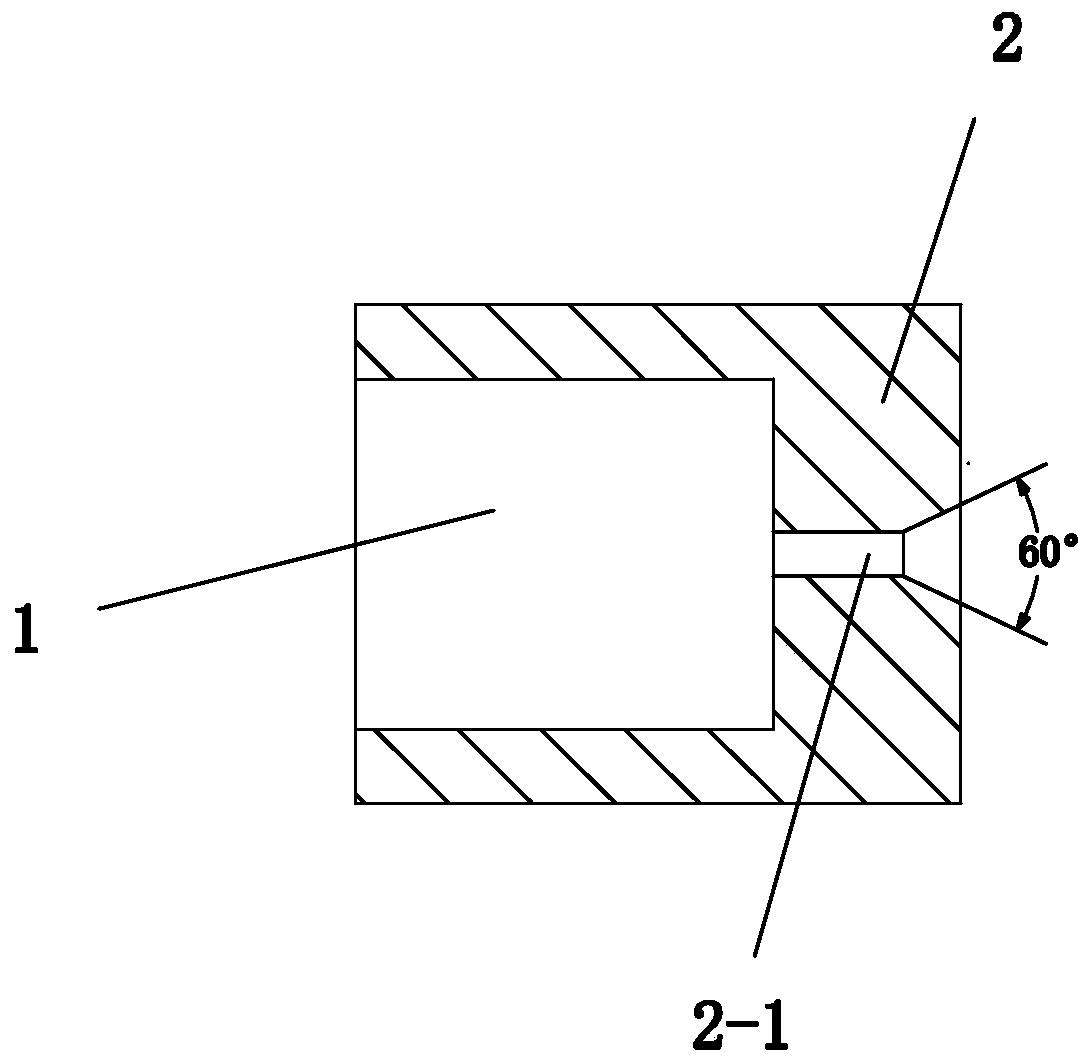

[0022] See figure 1 , the special high-speed steel combination roll for cold-rolled high-strength automobile sheet of the present embodiment is to be arranged on the high-speed steel roll body 1 that does not have center hole and the low-carbon low-carbon roll body that interference fit is installed on the two ends of high-speed steel roll body and is provided with center hole 2-1 The steel roll cover consists of 2.

[0023] The chemical composition and weight percentage of the high-speed steel roller body are as follows: carbon 0.85%; silicon 0.30%; manganese 0.30%; chromium 3.6%; molybdenum 4.30%; vanadium 1.60%; tungsten 5.40%; ; The rest is iron and unavoidable impurities.

[0024] The overall hardness of the high-speed steel roll body is 65.8HRC.

[0025] The chemical composition and weight percentage of the low carbon steel roller sleeve are as follows: carbon 0.52%; silicon 0.95%; manganese 0.35%; chromium 5.15%; molybdenum 1.30%; vanadium 0.45%; tungsten 1.30%; %; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com