A hydraulic forging device

A hydraulic and forging machine technology, which is applied to forging/pressing/hammer devices, driving devices of forging presses, forging presses, etc., can solve the problems of workers' personal safety threats, workers' physical exertion, and low processing efficiency, and achieve saving Manpower and material resources, avoid turning over and feeding operations, and ensure the effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

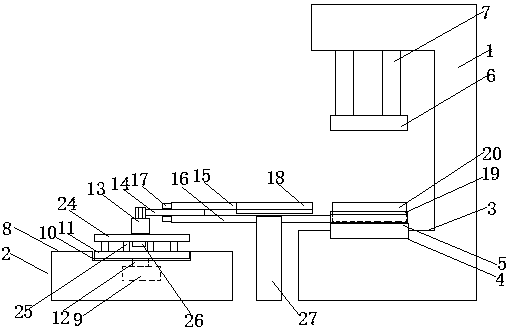

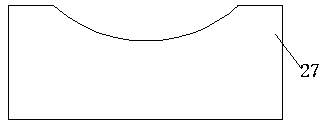

[0021] refer to Figure 1-4 , a hydraulic forging device, comprising a hydraulic forging machine 1 at the right end and an operating machine 2 at the left end, the lower part of the hydraulic forging machine 1 is a hydraulic workbench 3, and a groove 1 is arranged at the center of the surface of the hydraulic workbench 3 4. A lower mold table 5 is provided in the groove one 4, and an upper mold table 6 is arranged on the upper end of the lower mold table 5. The upper mold table 6 is connected to the hydraulic forging machine through a hydraulic push rod 7. 1 connected at the top;

[0022] The manipulator 2 includes a console 8 and a servo motor 9 located inside the console 8, a groove two 10 is provided at the center of the surface of the console 8, and a groove two 10 is provided in the groove two 10. Rotating plate 11, the rotating plate 11 is connected with the servo motor 9 through a rotating rod 12, a rotating cylinder 13 is provided above the rotating plate 11, and a ho...

Embodiment 2

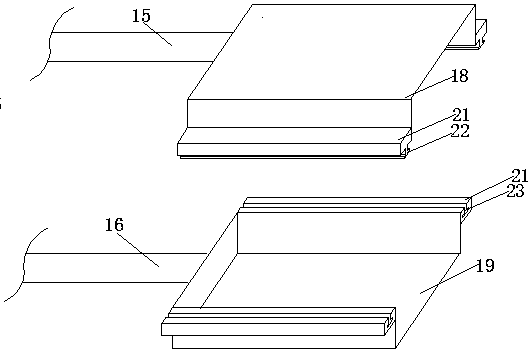

[0028] refer to Figure 5-6 , the difference from Embodiment 1 is that the upper package 18 is a separate upper and lower section structure, the upper telescopic rod 15 is welded on the left side of the lower section of the upper package 18, on the upper The left side of the two-stage structure of the package 18 is respectively provided with a protruding block 30, and the left and right ends of the protruding block 30 are respectively connected with a screw rod 31, and the bottom surface of the protruding block 30 at the lower end is in contact with the screw rod 31. A nut 32 is provided at the joint; this design can solve the problem that the package cannot adapt to workpieces of different heights, and only needs to use the screw rod 31 to adjust the distance between the upper and lower sections of the upper package 18. The structure is simple and the operation Convenience, the package does not have to be replaced several times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com