Modular all-direction aeration membrane assembly

An all-round, aeration membrane technology, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc., which can solve the problem of insufficient aeration scouring effect, easy blockage of aeration holes, and scalability of membrane modules. It is not strong enough to solve the problem of insufficient aeration and scouring effect, slow down membrane pollution, and achieve the effect of quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

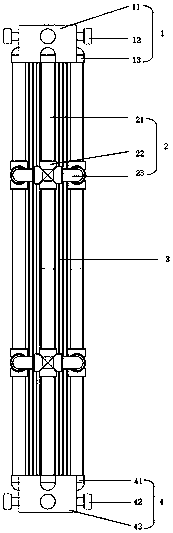

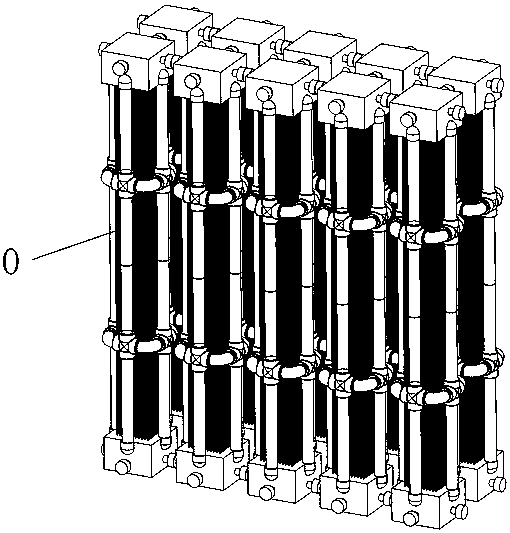

[0037] Example: a structure such as figure 1 As shown, a modular omni-directional aeration membrane assembly includes a suction head 1, an aeration pipeline 2, a membrane tow 3 and an aeration head 4.

[0038] The suction head 1 and the aeration head 4 are respectively placed at the two ends of the membrane tow 3 and fixed together with the two ends of the membrane tow 3 respectively. The membrane filament bundle 3 is composed of multiple hollow fiber membrane filaments arranged in parallel. The membrane filaments are hollow and there are many micron-sized pores on the membrane filament wall. Through the pumping action of the water pump, clean water penetrates into the membrane filaments from the tiny pores, and Contaminants are trapped on the outside.

[0039] The hollow fiber membrane is made of polyethylene (PE), vinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE) and other materials. The length is 500-5000mm, preferably the membrane filament bundle contains 400-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com