A kind of highly thixotropic colored marble glue and its preparation method

A technology of high thixotropy and colored marble, which is applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of thinning and flowing of colored marble glue, and reduce health threats , The preparation method is simple, the effect of improving the mechanical and thixotropic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 10

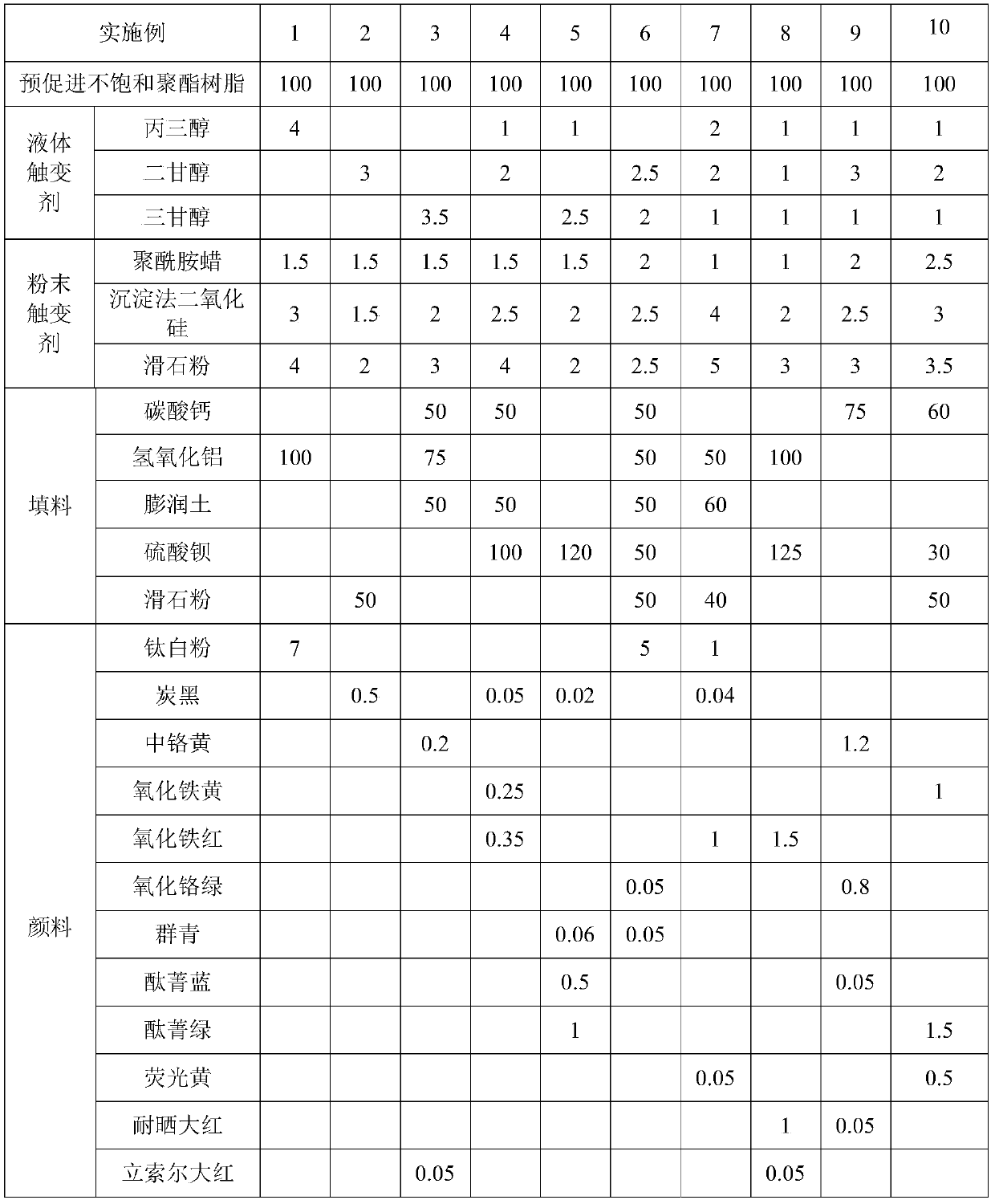

[0039] The high thixotropic colored marble glue of Examples 1 to 10, the specific components are listed in Table 1 (the data of marble glue in the table are parts by weight):

[0040] Table 1 High thixotropic colored marble adhesive components and preparation process conditions

[0041]

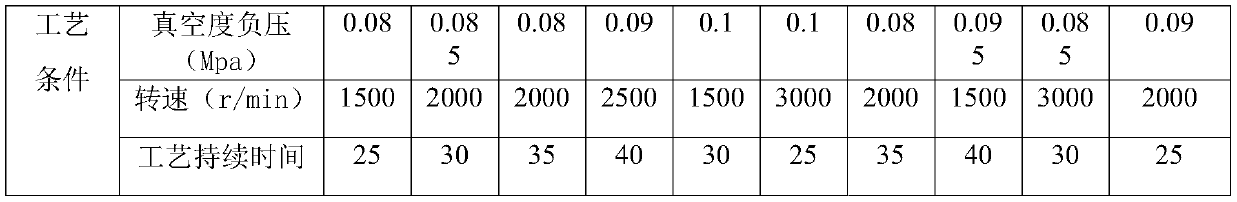

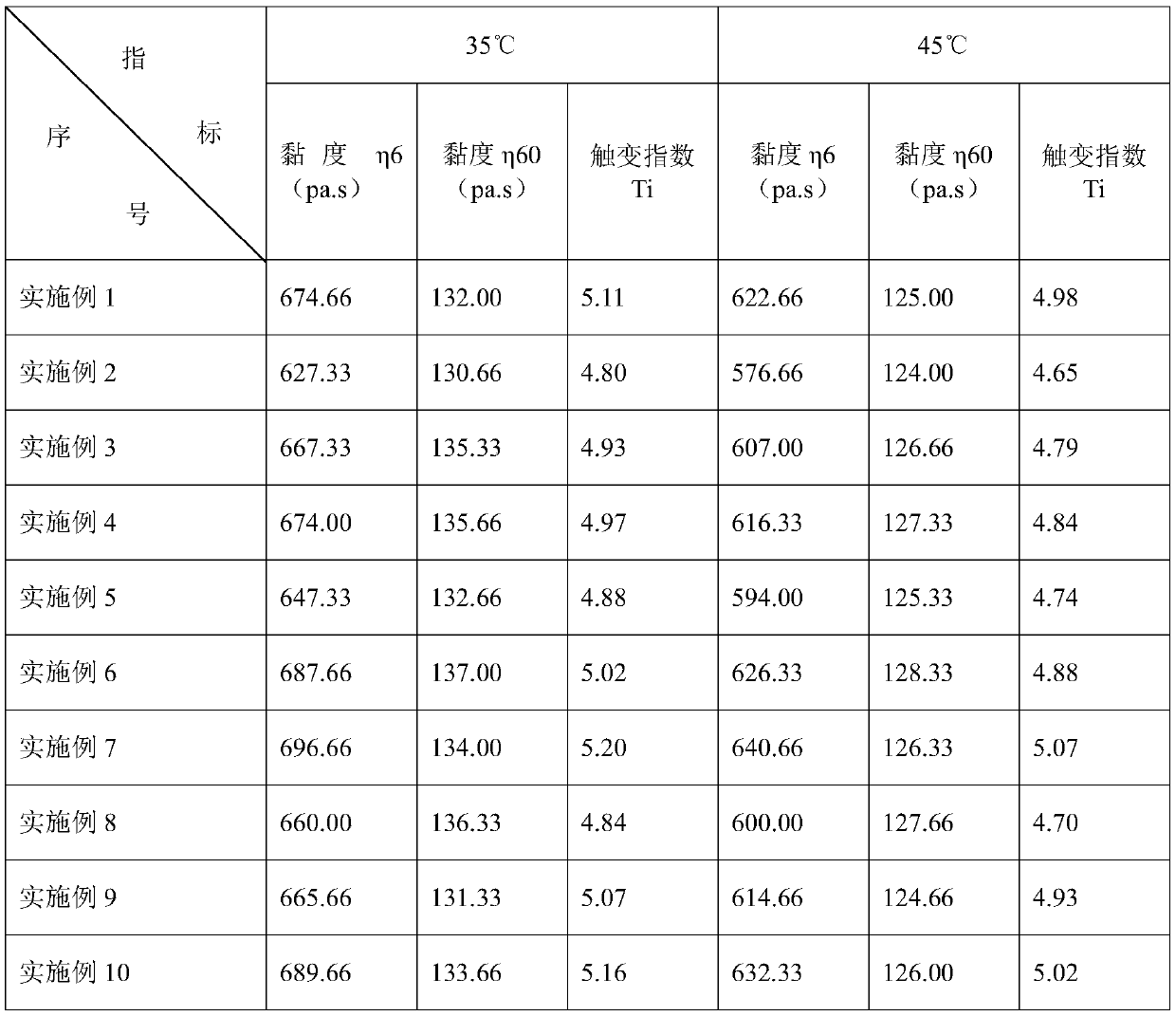

[0042]

[0043] The high thixotropic colored marble glue described in Examples 1 to 10 of the present invention can be prepared by accurately weighing the formula components of Examples 1-10 in Table 1, and then following the process conditions in Table 1 and performing ultrasonic dispersion at the same time.

[0044] According to GB / T 2794-2013 "Determination of Viscosity of Adhesives", the high thixotropic colored marble glue prepared above was used with SNB-3 digital rotational viscometer (Shanghai Nirun Intelligent Technology Co., Ltd.), and the 4th grade was selected. The rotors were tested at 35°C, 45°C, 55°C and 65°C at the speeds of 6r / min and 60r / min respectively, the viscosity...

Embodiment 16

[0074] Example 16: Stir at high speed under a negative pressure of 0.08Mpa and a rotating speed of 1500r / min, and carry out ultrasonic dispersion at the same time, and the duration is 30 minutes;

Embodiment 17

[0075] Example 17: Stir at high speed under a negative pressure of 0.1 Mpa and 1500 r / min at a rotational speed, and at the same time carry out ultrasonic dispersion for 30 minutes.

[0076] As shown in Table 5, under the process conditions of 1500r / min high-speed stirring under normal pressure and 1500r / min high-speed stirring under normal pressure and 1500r / min high-speed stirring under normal pressure, and ultrasonic dispersion at the same time or under negative pressure 0.08Mpa Stir at a low speed of 800r / min, and carry out ultrasonic dispersion at the same time. The duration of 30 minutes cannot reach the process conditions described in the present invention. The negative pressure is 0.08Mpa or 0.1Mpa, and the rotating speed is under the negative pressure state of 1500r / min. The effect of ultrasonic dispersion can only make the high thixotropic colored marble glue overcome the shortcomings of existing marble glue that is thin or even flowing at medium and high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com