Magnetization-free electromagnetic pure iron with high bending resistance and manufacturing method thereof

A technology of electromagnetic pure iron and manufacturing method, which is applied in the field of magnetization-free electromagnetic pure iron and its manufacturing, and can solve the problems of limited output, high cost, high requirements for annealing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

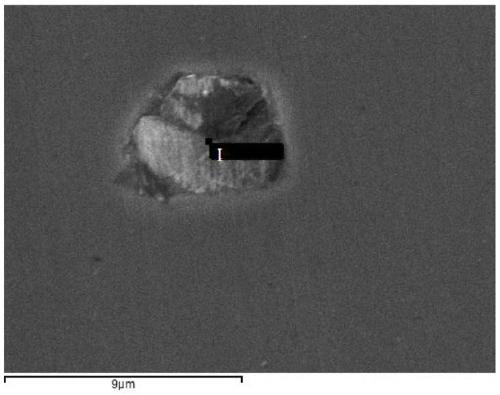

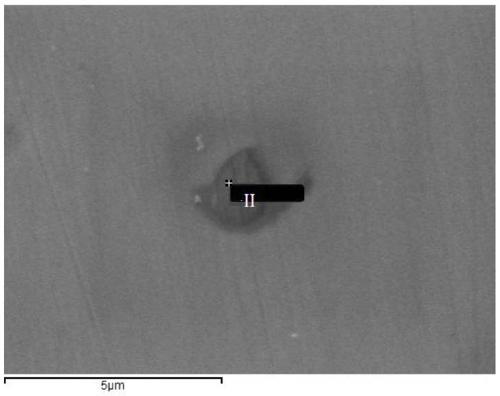

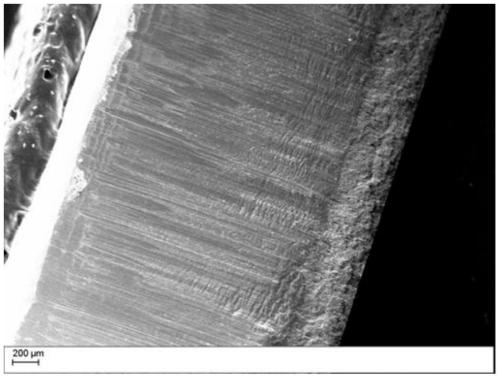

Image

Examples

Embodiment Construction

[0052] The magnetization-free electromagnetic pure iron with high bending resistance characteristics and its manufacturing method described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples. constitute an improper limitation.

[0053] The electromagnetic pure iron in each embodiment of the technical solution adopts the following steps to make:

[0054] (1) Smelting and continuous casting: smelting and continuous casting are made into slabs according to the mass percentage of each chemical element in Table 1;

[0055] (2) Hot rolling: control the heating temperature at 1100-1250°C; finish rolling temperature at 800-920°C; coiling temperature at 550-720°C;

[0056] (3) pickling;

[0057] (4) cold rolling, the control cold rolling reduction is 25-80%;

[0058] (5) Recrystallization annealing: Bell furnace annealing is used to heat the cold-rolled sheet to a soaking temperature of 500-650°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com