Marine drill pipe connector

A drill pipe joint and marine technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of reducing ROP, increasing friction coefficient, increasing torque, etc., to avoid local erosion, reduce joint wear, avoid deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

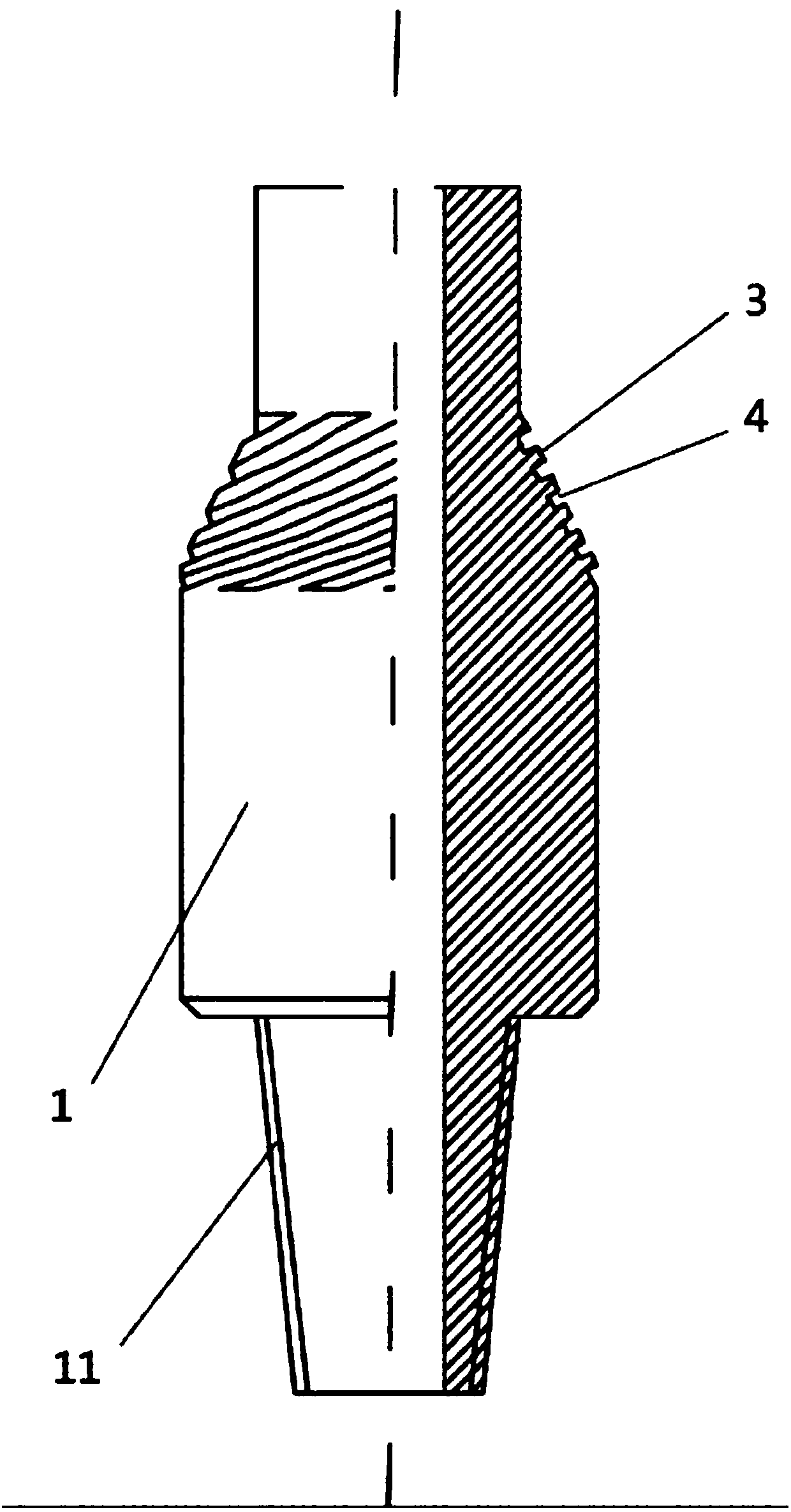

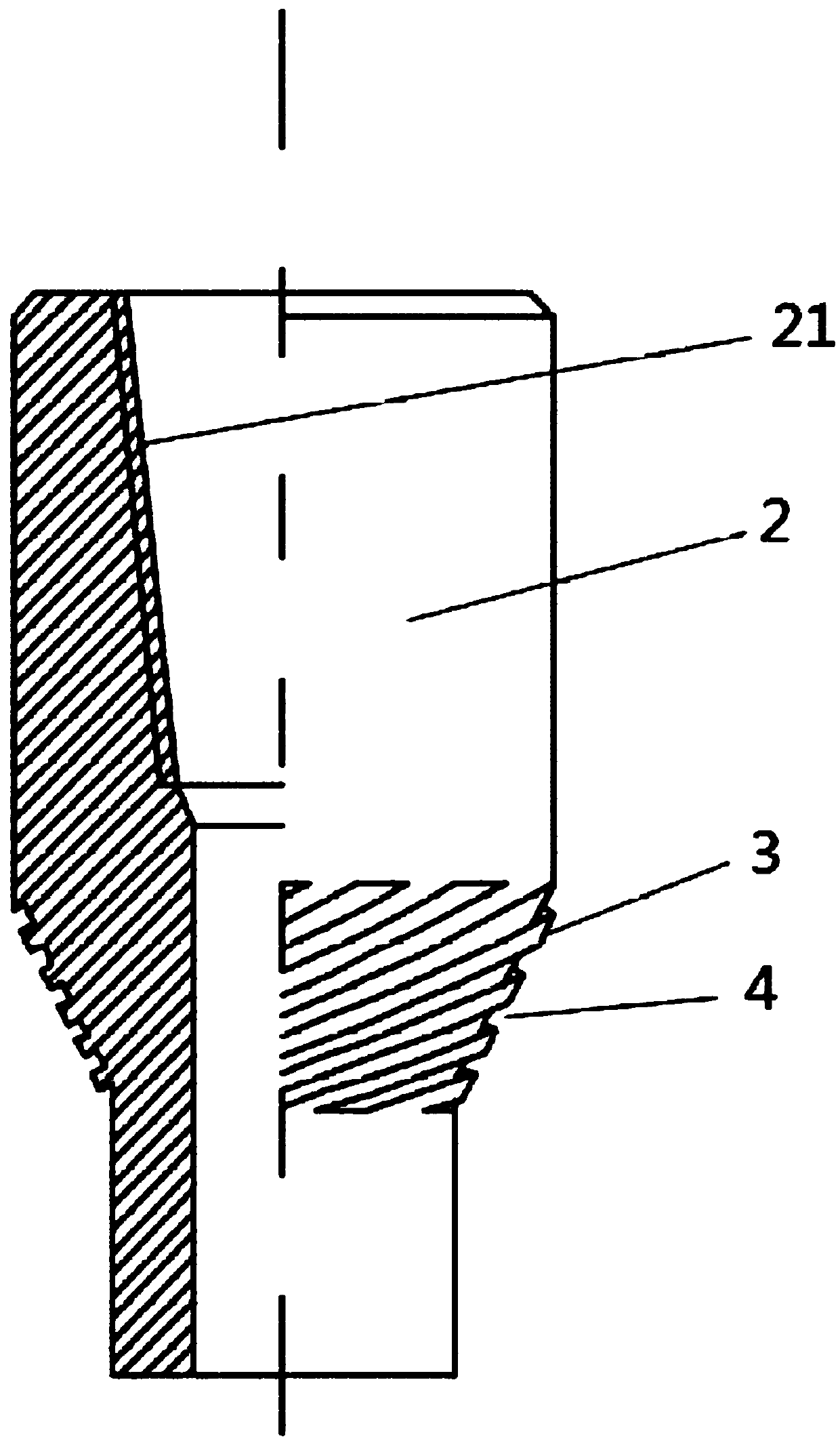

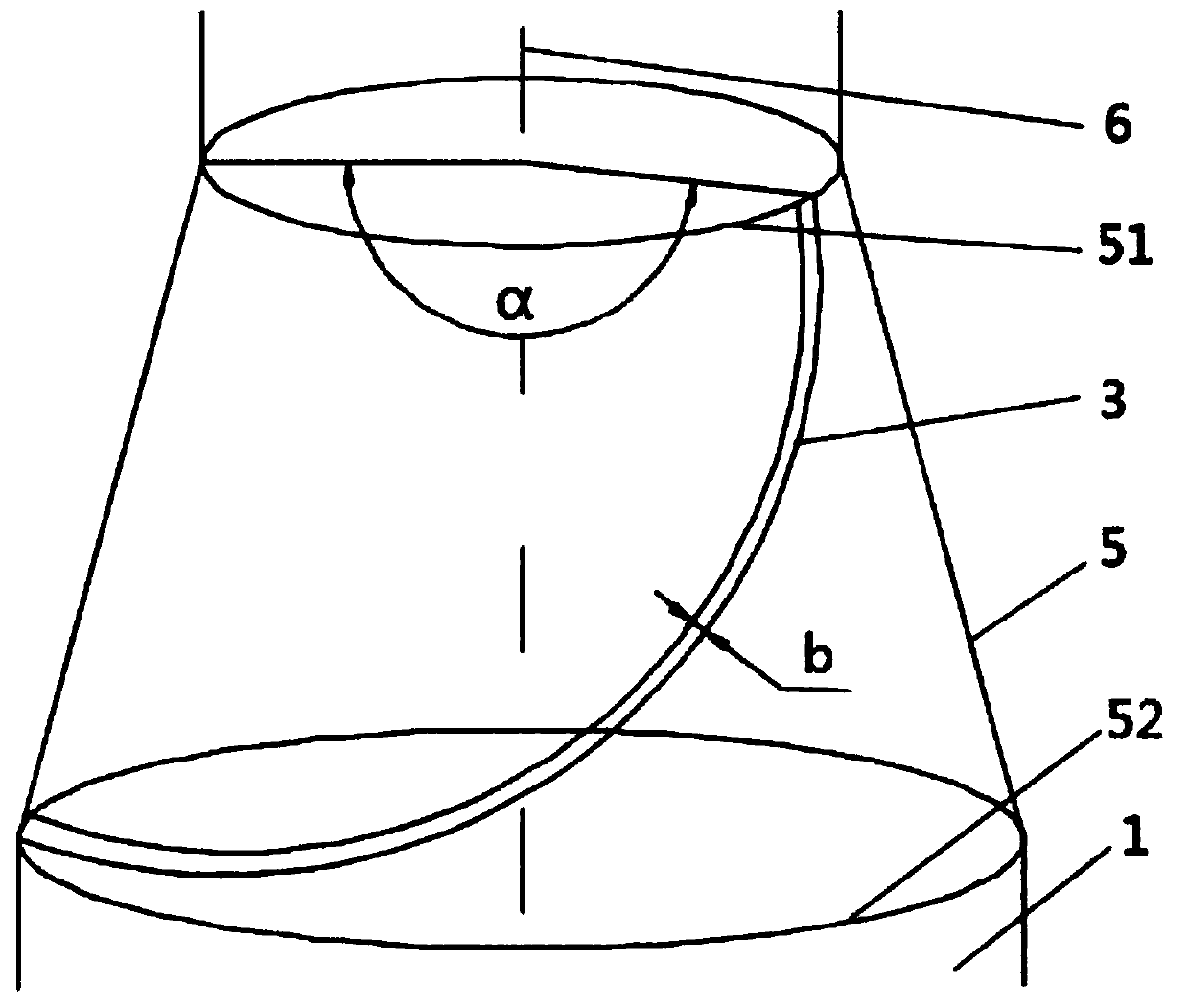

[0023] A marine drill pipe joint, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes: a male connector 1 and a female connector 2. The male connector 1 and the female connector 2 have external threads 11 and internal threads 21 that match each other. One end of the internal thread 21 is provided with a tapered shoulder 5, and several reinforcing ribs 3 of spiral structure are arranged at intervals on the tapered shoulder 5, and a spiral groove 4 is formed between adjacent reinforcing ribs 3. The spiral extension of the reinforcing rib 3 along the outer surface of the tapered shoulder 5 may be clockwise or counterclockwise, which is selected according to actual needs.

[0024] The transverse cross-sectional shape of the reinforcing rib 3 can be various, such as triangle, trapezoid, etc., and the preferred transverse cross-section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com