Thick copper circuit board with 12 OZ outer layer and solder-resist manufacturing method of thick copper circuit board

A technology of thick copper circuit board and manufacturing method, which is applied in the directions of printed circuit manufacturing, printed circuit, and printed circuit secondary processing, etc. Problems such as poor thickness uniformity can save costs and production time, improve reliability and quality, and avoid uneven ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

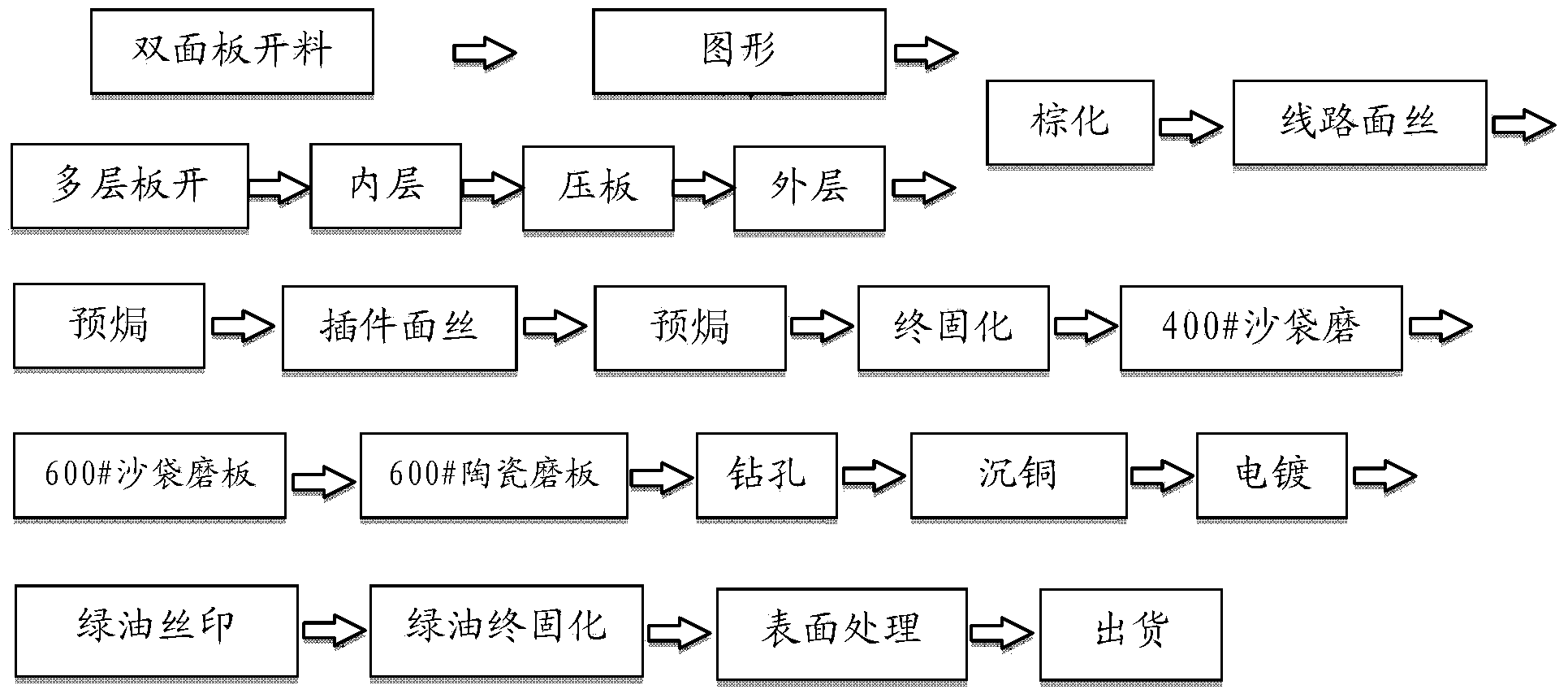

[0072] A kind of anti-soldering manufacturing method of outer layer 12OZ thick copper circuit board, comprises the following steps (flow chart sees figure 1 ):

[0073] (1) Browning of the outer circuit board; the weight percentage of sodium hypochlorite is 4.3%, the weight percentage of hydrogen peroxide is 4.8%, the temperature is 35°C, and the etching rate is 1.5 μm / cm 2 .

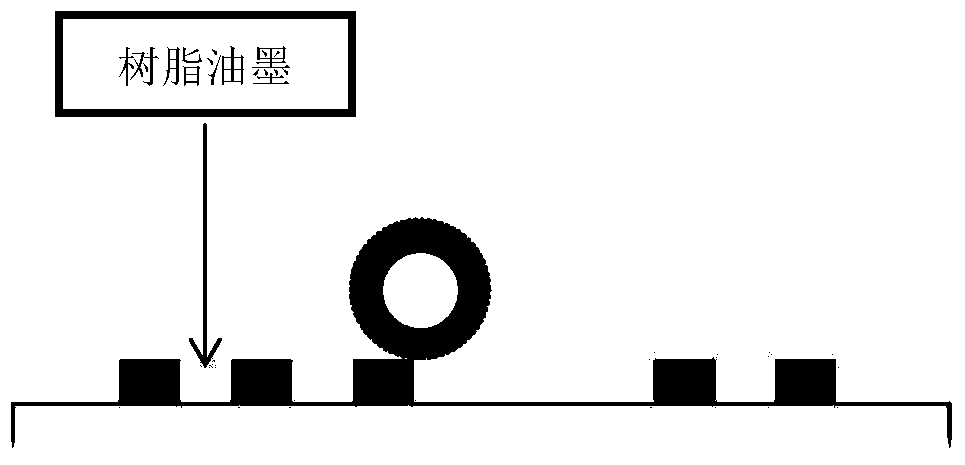

[0074] (2) Resin coating between 12OZ lines: use silk screen printing method to coat Shanrong special line resin ink between lines, let stand for 20min until the bubbles overflow, and then pre-bake and solidify; the technical parameters of the silk screen method are: : The angle of the squeegee of the screen printing machine is 25°, the thickness of the squeegee is 30mm, and the screen is slanted at 15° to print; Baking parameters: temperature is 120°C, time is 45min, curing parameters: temperature is 180°C, time is 60min;

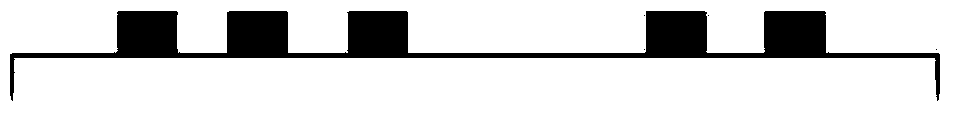

[0075] (3) Grinding plate: 2 sandbag grinding plates and 1 ceramic grinding ...

Embodiment 2

[0095] The solder resist manufacturing method of the outer layer 12OZ thick copper circuit board described in the present embodiment, the steps are basically the same as in Embodiment 1, the difference is that:

[0096] (1) Browning of the outer circuit board: the weight percentage of sodium hypochlorite is 4%, the weight percentage of hydrogen peroxide is 4%, the temperature is 32°C, and the etching rate is 1.45 μm / cm 2 .

[0097] (2) Resin coating between lines: The technical parameters of the screen printing method are: the angle of the squeegee of the screen printing machine is 20°, the length of the squeegee is 25mm, and the screen is drawn at 13°; Method Pre-baking parameters of printed plug-in surface, line surface and plug-in surface: temperature is 110°C, time is 40min, curing parameters: temperature is 170°C, time is 50min;

[0098] (3) Grinding plate: use 1 sandbag grinding plate and 1 ceramic grinding plate, that is, use 400# sandbag grinding plate-600# ceramic gr...

Embodiment 3

[0109] The solder resist manufacturing method of the outer layer 12OZ thick copper circuit board described in the present embodiment, the steps are basically the same as in Embodiment 1, the difference is that:

[0110] (1) Browning of the outer circuit board: the weight percentage of sodium hypochlorite is 5%, the weight percentage of hydrogen peroxide is 6%, the temperature is 38°C, and the etching rate is 1.6 μm / cm 2 .

[0111] (2) Resin coating between lines: the technical parameters of the screen printing method are: the angle of the squeegee of the screen printing machine is 30°, the length of the squeegee is 35mm, and the screen is 17° inclined; In the same way, the pre-baking parameters of the Indy plug-in side, the circuit side and the plug-in side: the temperature is 130°C, the time is 50min, and the curing parameters: the temperature is 190°C, the time is 70min;

[0112] (3) Grinding plate: use sandbag grinding plate 3 times and ceramic grinding plate 2 times, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com