Electrode slurry and preparation method thereof

A technology of electrode paste and glass powder, which is applied in the direction of cable/conductor manufacturing, circuit, and conductive materials dispersed in non-conductive inorganic materials, etc., and can solve problems such as high energy consumption, product microcracks, and appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

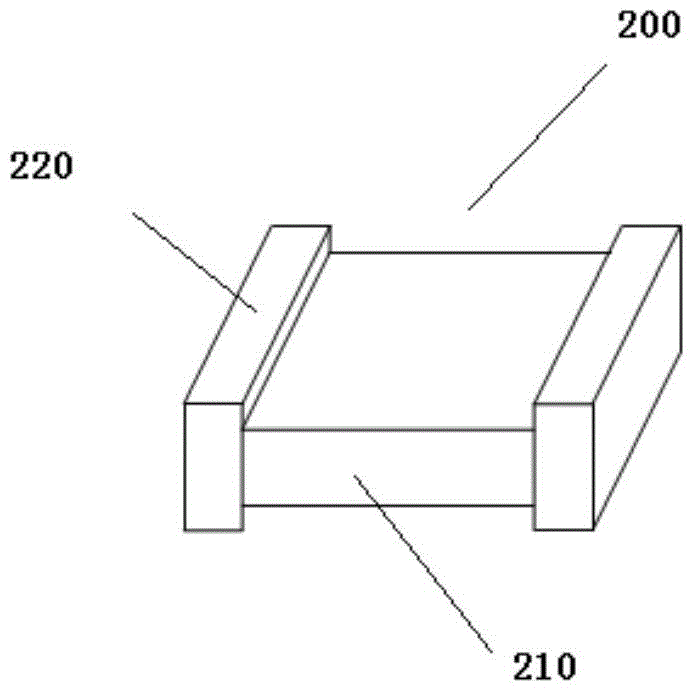

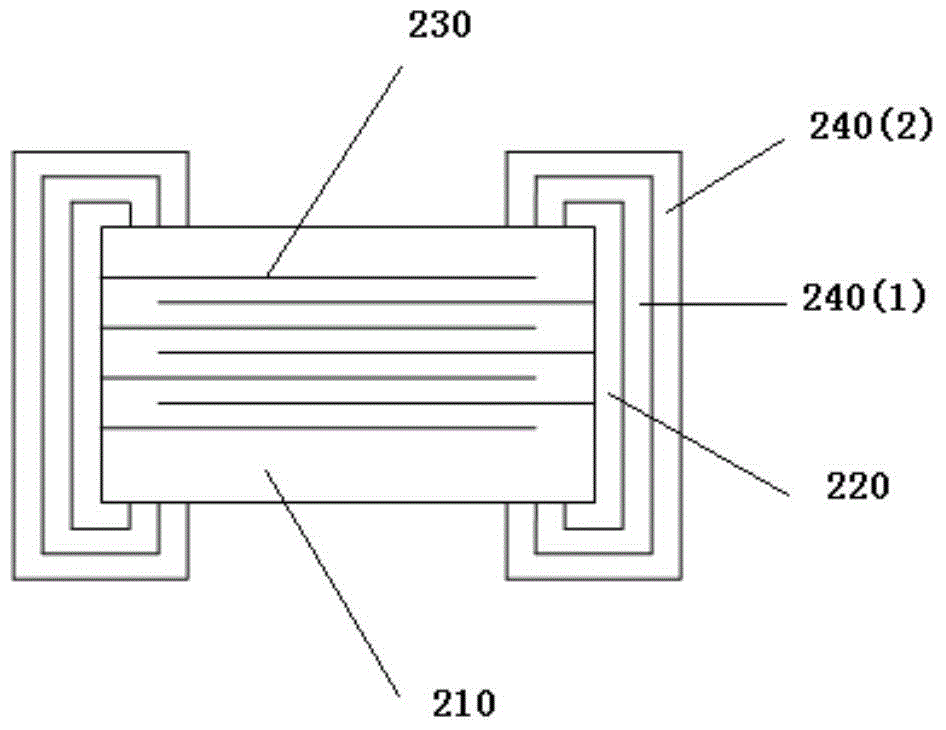

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned electrode slurry, comprises the following steps:

[0035] Step S110, by mass percentage, 10% to 20% of ZnO, 2% to 10% of B 2 o 3 , 15% to 30% SiO 2 , 30%~50% BaO, 2%~10% CaO, 0~10% CuO, 0~10% Al 2 o 3 , 1% ~ 8% Na 2 O, 2% to 8% Nb 2 o 5 Made into glass powder.

[0036] In this embodiment, the above-mentioned components are mixed, melted at high temperature, quenched, ball milled and granulated, dried and sieved to obtain a glass powder with good dispersibility and uniform composition. Of course, other methods in the industry can also be used to prepare glass powder.

[0037] Preferably, the particle size of the prepared glass powder is 1 μm-7 μm.

[0038]Step S120 , adding the polymer resin into an organic solvent heated to 70° C. to 90° C. and dissolving it for 1 hour to 2 hours to obtain an organic binder.

[0039] Preferably, the organic solvent is heated to 70° C. to 90° C. in a water bath.

[0040] Preferably, th...

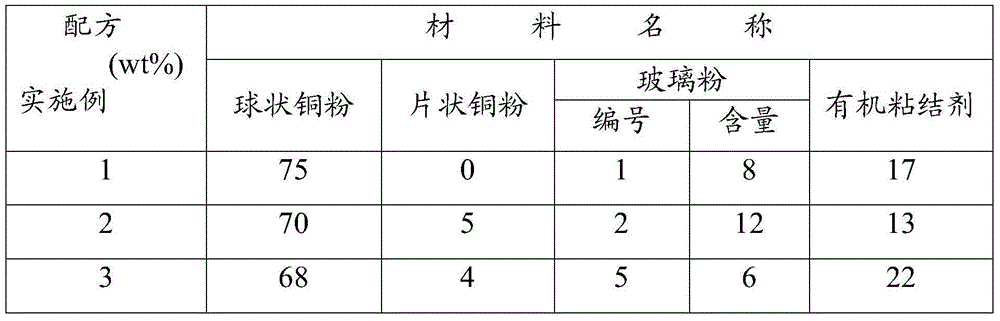

Embodiment 1~11

[0057] The preparation method of the electrode slurry of embodiment 1~10 is as follows:

[0058] Add the polymer resin into the heated organic solvent and dissolve it for 1 hour to 2 hours to obtain an organic binder; mix the oxides of each component in Table 2 through mixing, high temperature melting, quenching, ball milling, granulation, drying and sieving After treatment, glass powder with good dispersion and uniform particle size of 1 μm to 7 μm is obtained; spherical copper powder, flake copper powder, glass powder, and organic binder are mixed uniformly to obtain a mixture; the mixture is rolled by a three-roll mill The electrode slurry is prepared by grinding to obtain a paste with good dispersibility and certain requirements for fineness, viscosity and rheology.

[0059] The preparation method of the electrode slurry of embodiment 11 is as follows:

[0060] Add the polymer resin into the heated organic solvent and dissolve it for 2 hours to 3 hours to obtain an organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com