Exhaust fan

An exhaust fan and box technology, which is applied to the components of the pumping device for elastic fluid, non-variable-capacity pumps, pump devices, etc., can solve the problems of low efficiency and high noise of the exhaust fan, and reduce the The effect of noise, low noise and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

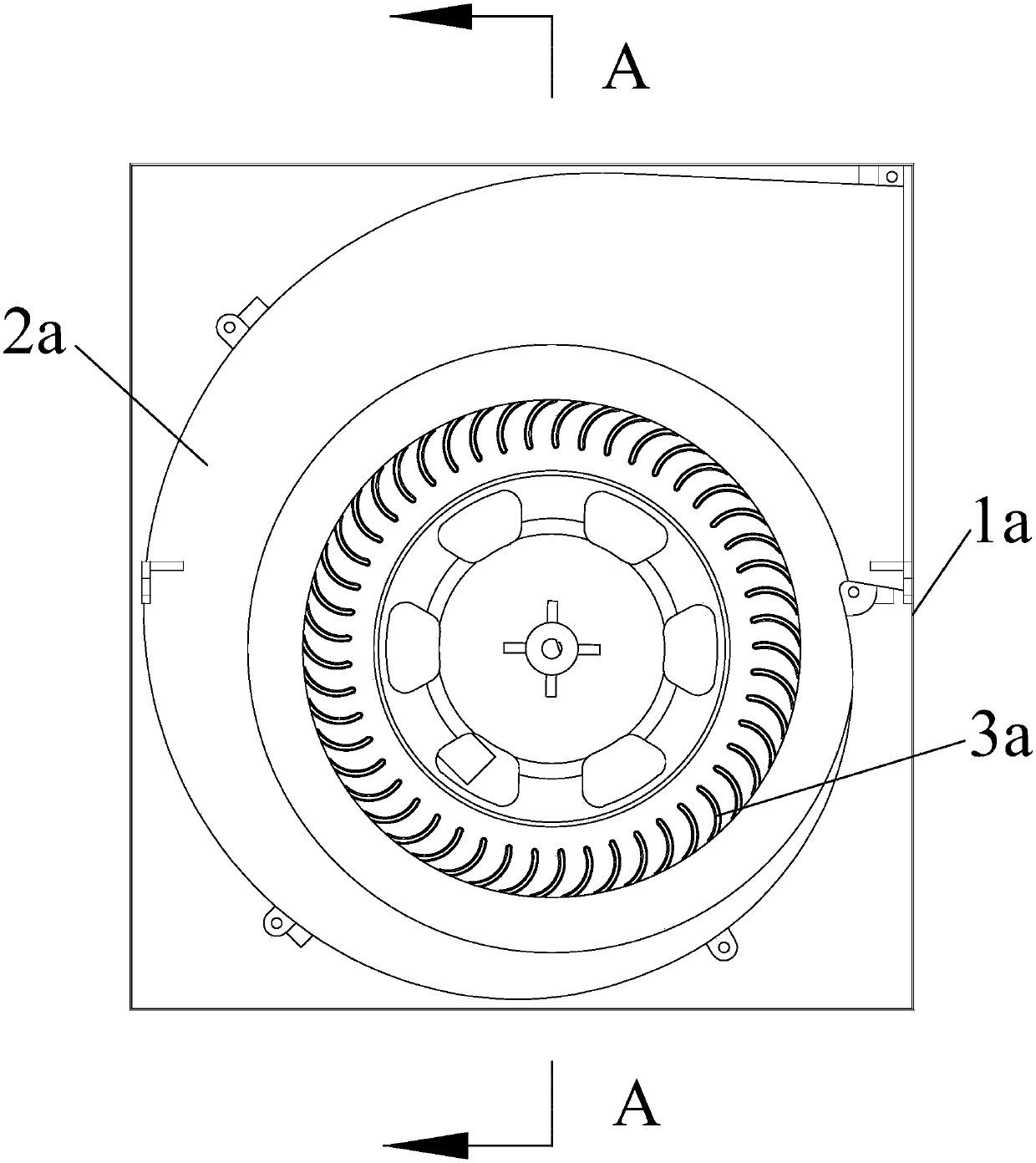

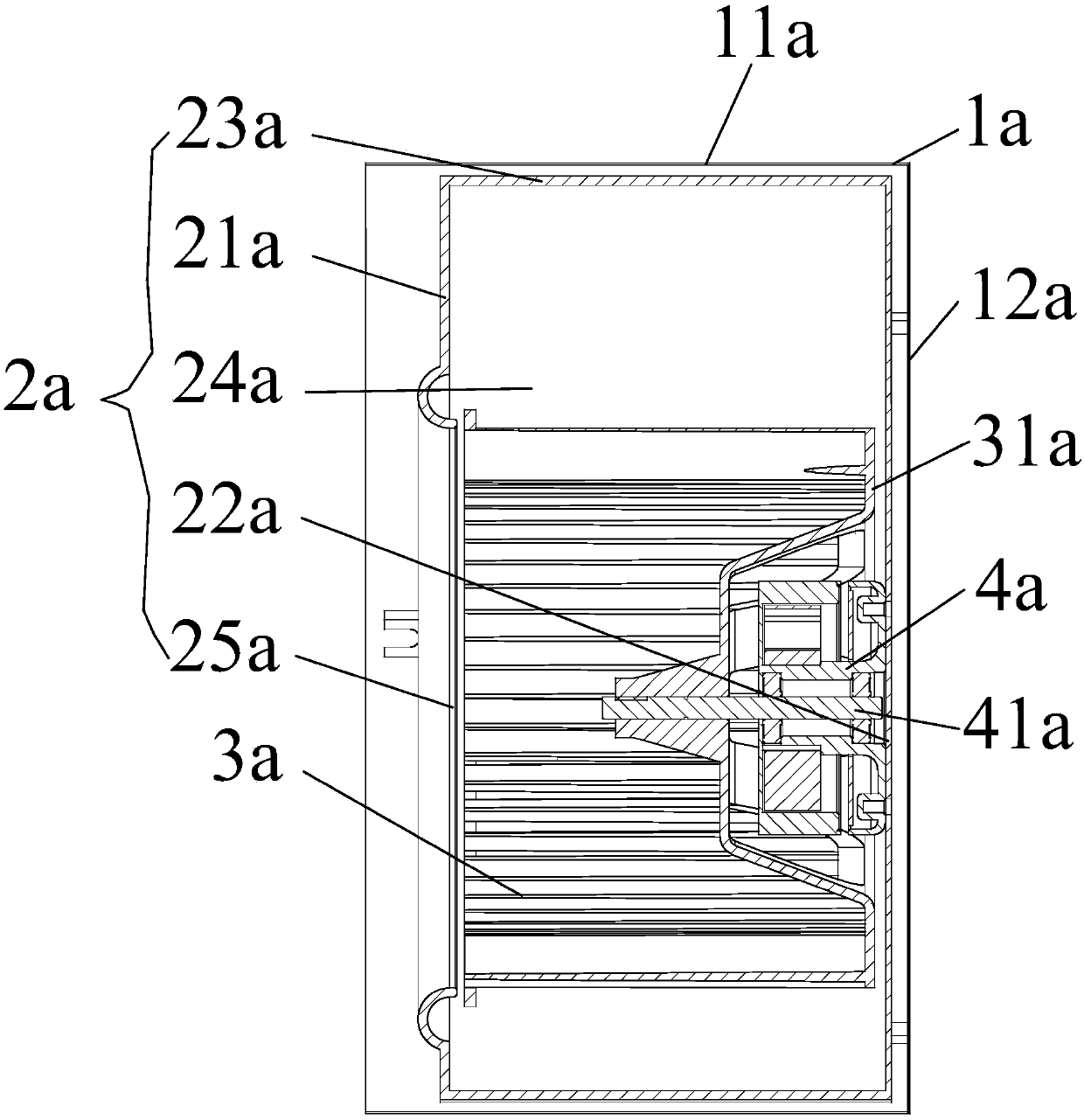

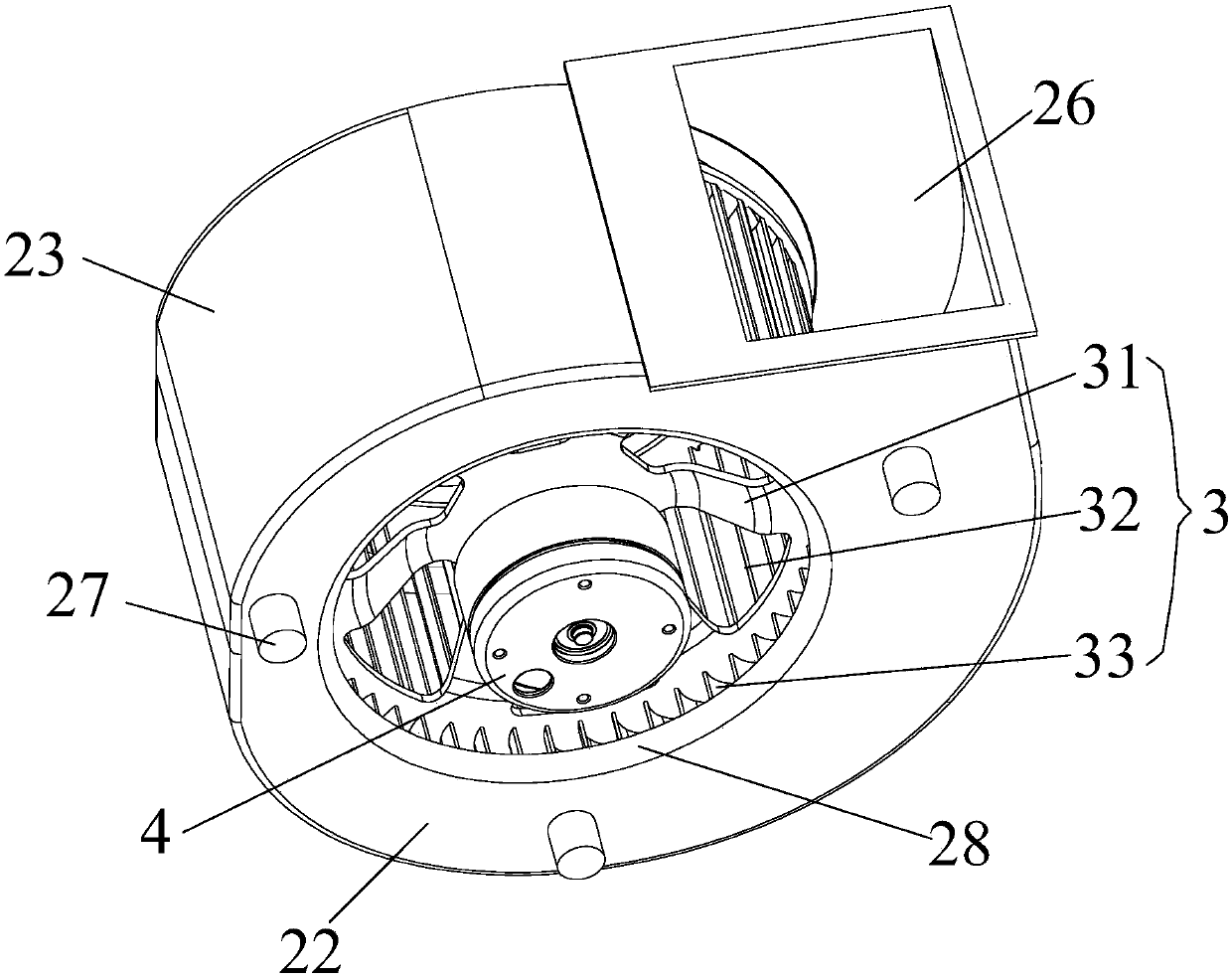

[0032] Such as Figure 3 to Figure 8 As shown, what this embodiment provides is an exhaust fan, including a box body 1 and a volute fan. The box body 1 includes a cover plate 11, a side plate 12 and a bottom plate 13. Bottom plate 13 encloses accommodating cavity, and described volute fan includes volute 2, wind wheel 3 and motor 4, and described volute 2 is fixed in the accommodating cavity of box body 1, and described volute 2 comprises front end Plate 21, rear end plate 22 and side plate 23 connected between front end plate 21 and rear end plate 22, front end plate 21, rear end plate 22 and side plate 23 enclose cavity 24, wind wheel 3 is arranged in the cavity 24, the cover plate 11 is provided with a slit 110, the side plate 12 is provided with an opening 120, the front end plate 21 is provided with a first air inlet 25, and the side panel 23 is provided with an air outlet 26, so The slit 110, the first air inlet 25, the cavity 24, the air outlet 26 and the opening 120 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com