High temperature superconducting magnetic levitation low temperature working medium transportation pipeline structure

A low-temperature working fluid, high-temperature superconducting technology, which is used in thermal insulation, pipeline protection, and protection of pipelines through thermal insulation, etc., can solve problems such as pipeline pressure rise, conductive heat leakage, etc., to save space, simplify structure, and improve utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

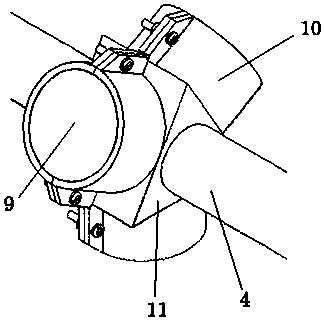

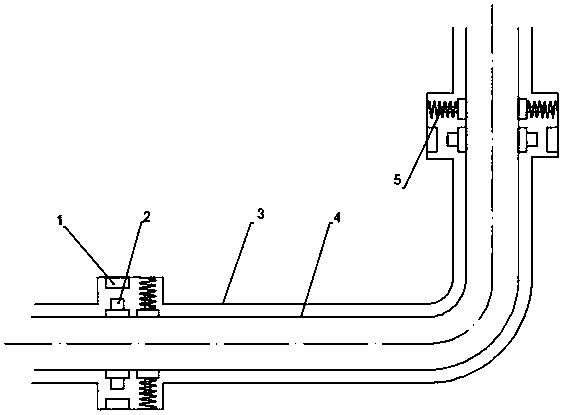

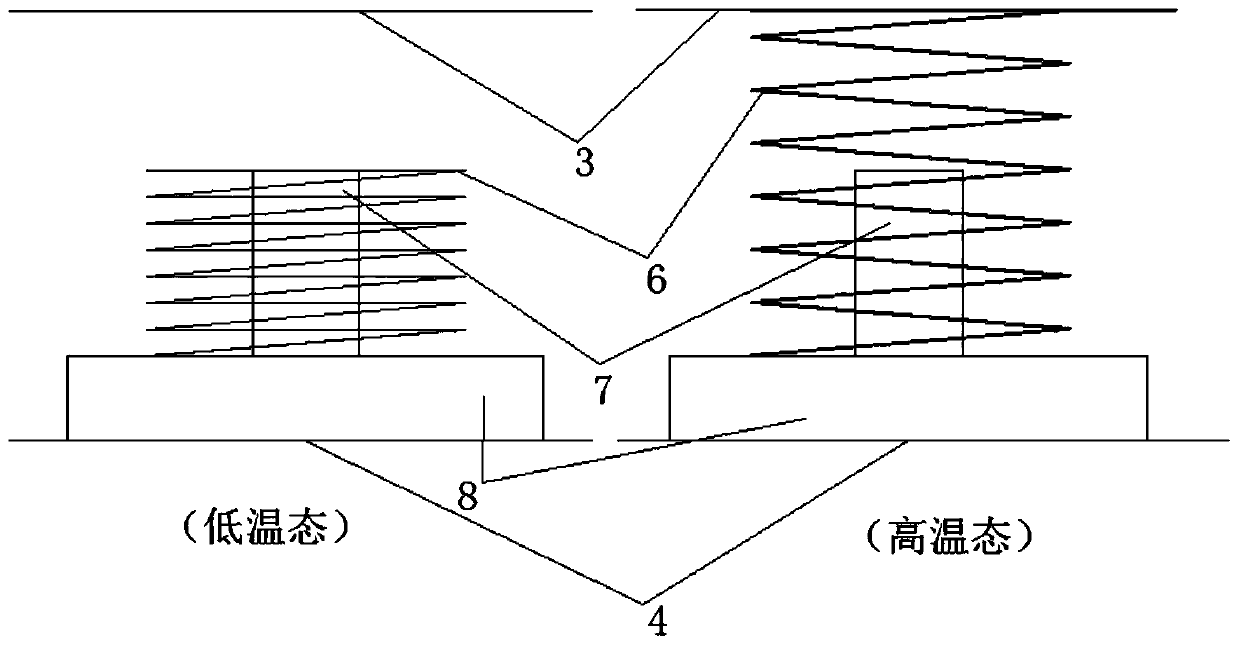

[0022] The superconductor component 2 and memory alloy component 5 are adjacently fixed on the low temperature inner tube 4 . The permanent magnet 1 is correspondingly fixed on the inner side of the outer tube 3 along the axial direction, and is located on the outer side of the superconductor assembly 2 at the same time. The memory alloy spring 6 is sleeved on the guide column 7 and fixed on the memory alloy spring installation base 8 . The superconductor 9 is fixed on the superconductor installation base 11 through two semicircular red copper clamping lugs 10 .

[0023] Superconductor 9 The superconducting critical temperature is required to be above the cryogenic working fluid temperature, and superconductors with different superconducting critical temperatures can be selected according to the working fluid temperature. For liquid hydrogen (boiling point 22K), cylindrical YBCO superconductor (critical temperature 90K) can be used.

[0024] The cryogenic working fluid is tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com