Mobile tank type cooler and sintered ore cooling method

A cooler and mobile tank technology, which is applied in the field of mobile tank coolers and sinter cooling, can solve problems such as difficult to achieve sinter cooling, failure to meet the output requirements of sinter machines, etc., and achieve simple and automatic operation, uniform and stable flow field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

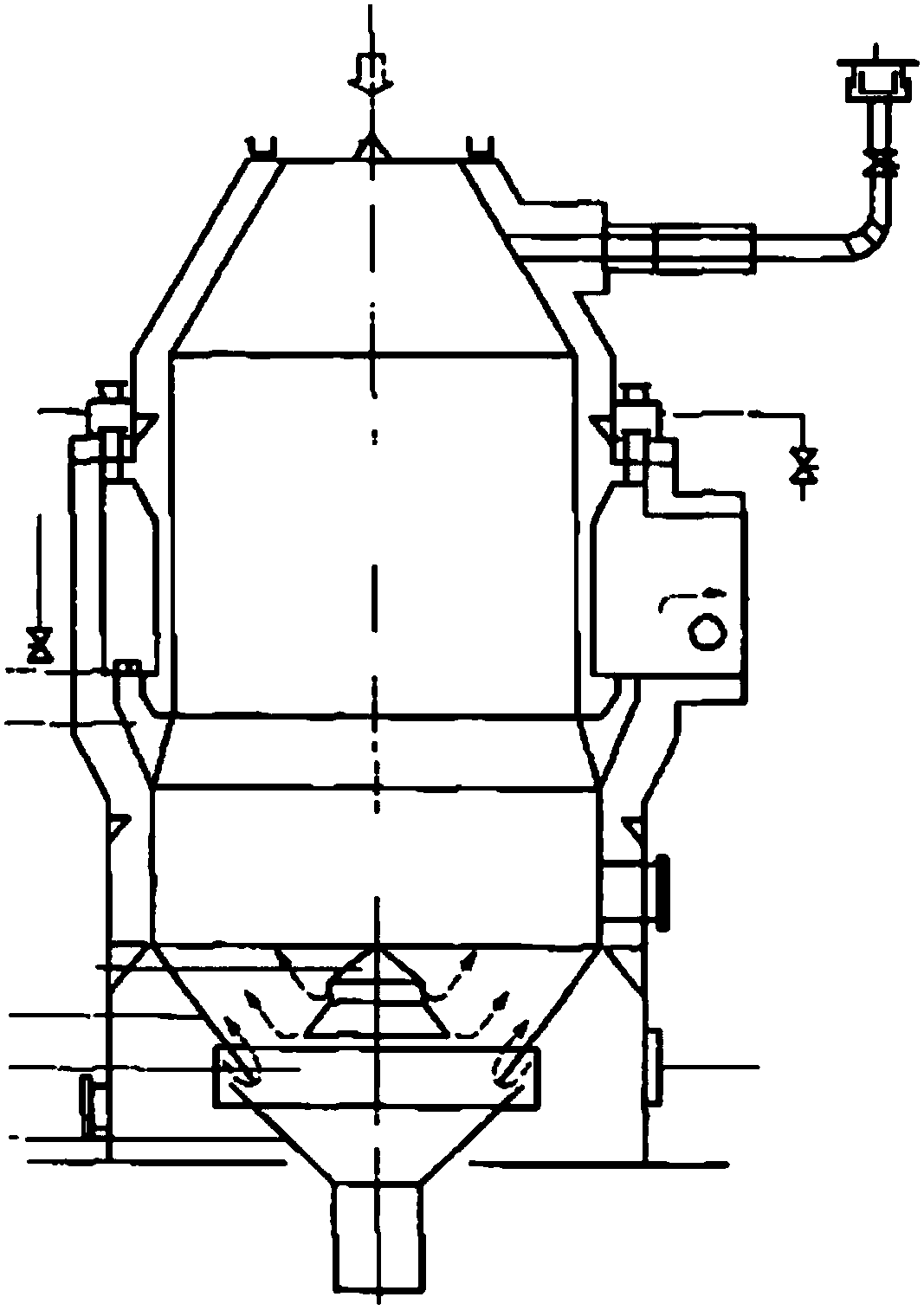

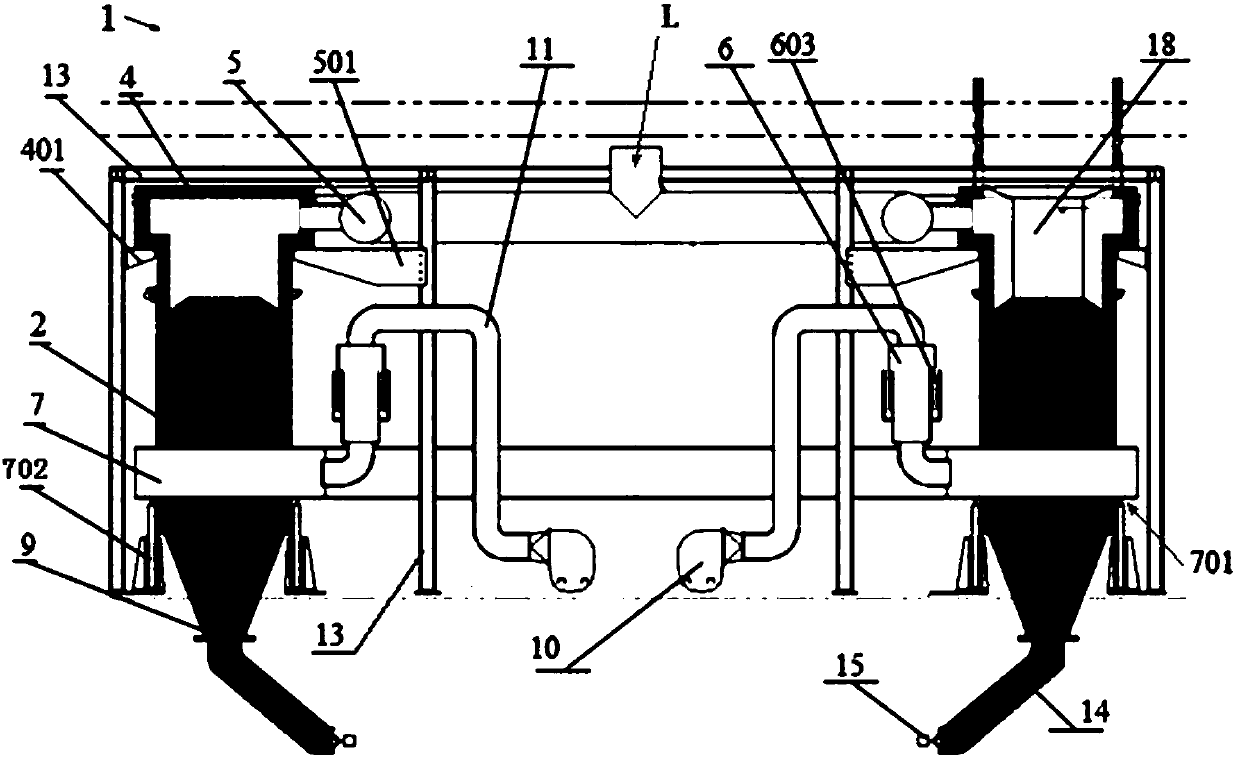

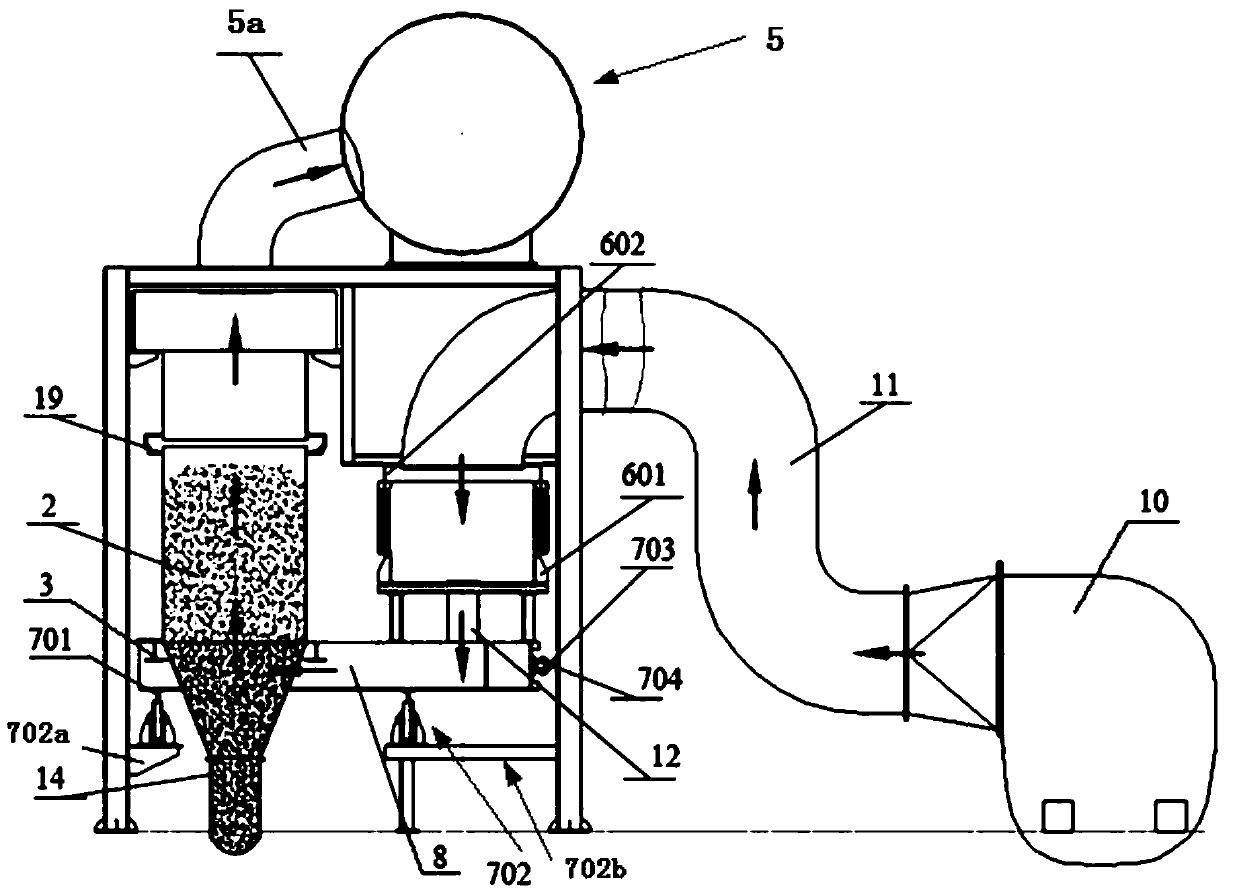

[0102] Such as figure 2 , image 3 and Figure 4 , a mobile tank cooler 1, the cooler includes: the sintered ore from the sintering machine is stacked from the top of the annular groove cooling bin 2, wherein the upper part of the annular groove cooling bin 2 is provided with a feed hopper 17, and the annular groove A feed chute 18 is provided above the inner top of the shape cooling bin 2, wherein the feed hopper 17 communicates with the feed chute 18; the driving device 3 for driving the above-mentioned annular groove cooling bin to make a rotary motion in the horizontal direction; The annular hot air cover 4 provided on the trough-shaped cooling bin and covering the upper part of the above-mentioned annular trough-shaped cooling bin, the hot-air cover sealing device 19 is arranged between the annular trough-shaped cooling bin 2 and the hot-air cover 4; it is connected to the top of the above-mentioned hot-air cover 4 4 hot air collecting pipes 5, the hot air collecting p...

Embodiment 2

[0105] Such as Figure 5 and Figure 6 As shown, embodiment 1 is repeated, except that the cooling air duct 6 is arranged outside the annular groove-shaped cooling bin 2 .

Embodiment 3

[0107] Repeat embodiment 1, just change the first mine row device 15 into the second mine row device 16. Such as Figure 8 , the second ore discharge device 16 includes a hanging seat 1601, a hanging sleeve 1602, a second control wheel 1603, an anti-blocking groove 1604, a lifting track 1605, a second counterweight 1606 and a second discharge door 1607, wherein the lifting track 1605 Set at the exit of the unloading section, the entrance of the unloading section is provided with a bumper, the second unloading door 1607 is vertically set on the lower edge of the ore discharge pipe 14, and the hanging seat 1601 is installed on the ore discharge pipe 14 the upper edge of the nozzle, the hanging sleeve 1602 is arranged on the upper part of the second discharge door 1607, the second control wheel 1603 is installed on the middle part of the second discharge door 1607, and the second counterweight 1606 is arranged on the second discharge door 1607 In the lower part, the anti-blockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com