Non-destructive detection method for detecting crimping quality of tension-resistant wire clamp by utilizing ultrasonic phased array

A technology of ultrasonic phased array and strain clamp, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problem of crimping position and crimping quality detection Difficulties and other problems, to achieve the effect of improving work efficiency, ensuring safe operation, and clear images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

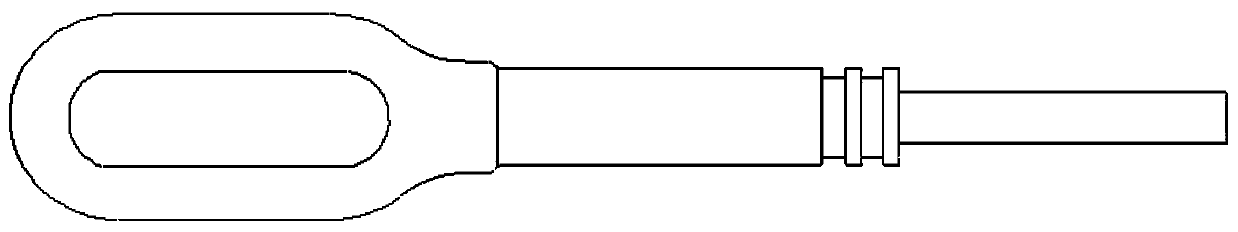

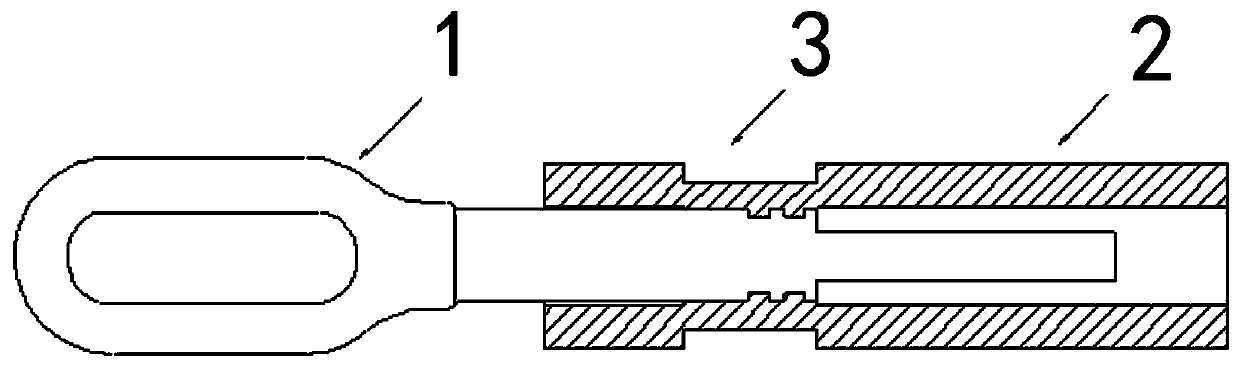

[0034] The invention is a non-destructive testing method for testing the crimping quality of strain-resistant clamps by using ultrasonic phased array, and the specific implementation steps are as follows:

[0035] (1) Select a crimping plane after the crimping of the tension clamp is completed as the detection surface;

[0036] (2) Set the workpiece parameters of the tested strain clamp joint, and adjust the ultrasonic phased array instrument.

[0037] Set up the ultrasonic phased array instrument according to the size parameters of the aluminum sleeve 2, adjust and calibrate the ultrasonic phased array instrument; apply glycerin with good sound transmission performance on the detection surface, so as to maintain a good coupling contact between the probe and the workpiece, Reduce energy loss after ultrasonic waves enter the workpiece;

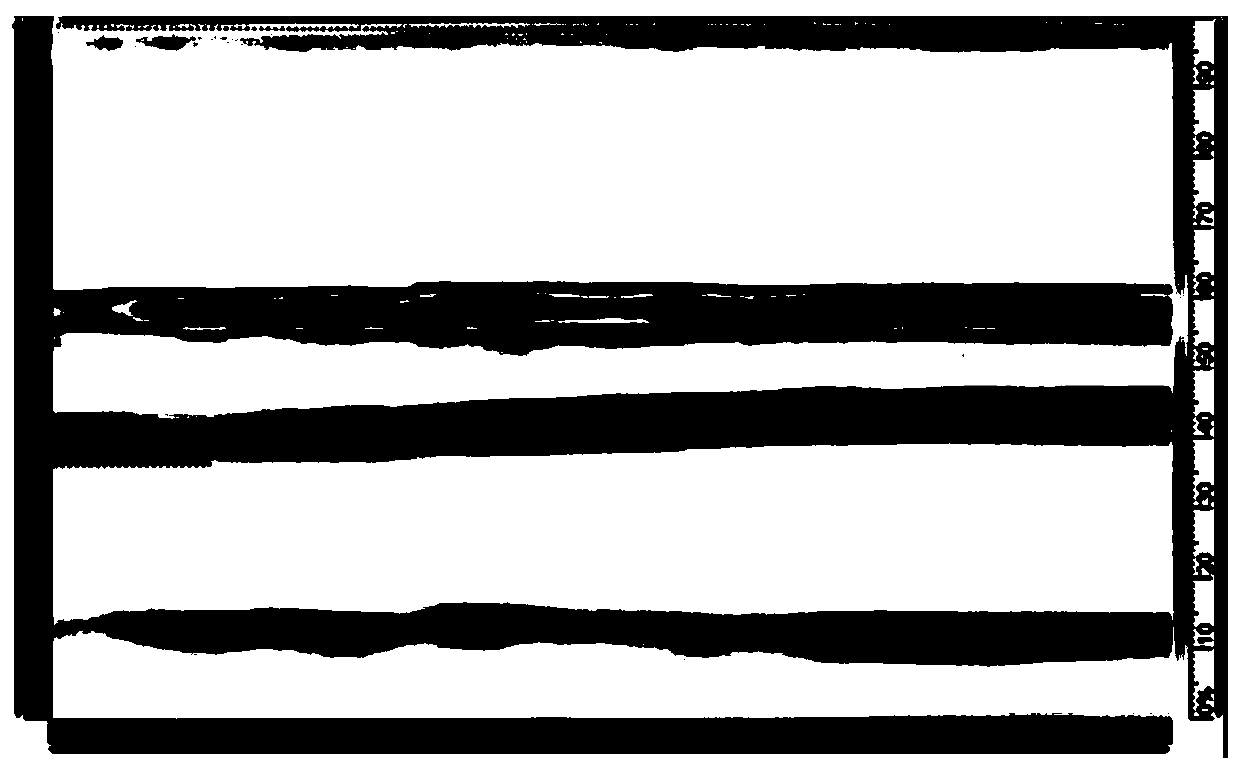

[0038] (3) Put the probe on the crimping plane, adopt the phased array longitudinal wave detection method, adjust the gain value and display ...

Embodiment 2

[0041] In this implementation case, the 500kV transmission line compression type strain clamp is selected for inspection and implementation, and the strain clamp model is: NY-630 / 45. The specific detection steps in this implementation case are as follows:

[0042] 1. Select one of the six crimping planes of the strain clamp as the detection surface;

[0043] 2. Measure the thickness of the aluminum casing by a thickness gauge to be 12mm;

[0044] 3. Apply glycerin with good sound transmission performance on the detection surface, so as to maintain good contact between the probe and the workpiece, and reduce the energy loss after the ultrasonic wave enters the workpiece;

[0045] 4. Set the parameters of the tension clamp joint to be tested, select the longitudinal wave detection method, and the focus depth is 12mm±0.5mm; excite 1-128 chips of the phased array probe.

[0046] 5. Adjust the sound velocity and delay of the ultrasonic phased array instrument through the test blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com