Visual inspection algorithm for outline

A visual detection and contour technology, applied in computing, computer parts, image data processing, etc., can solve problems that have not yet been published in literature or reports, and achieve the effects of improving production efficiency, high computing efficiency, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

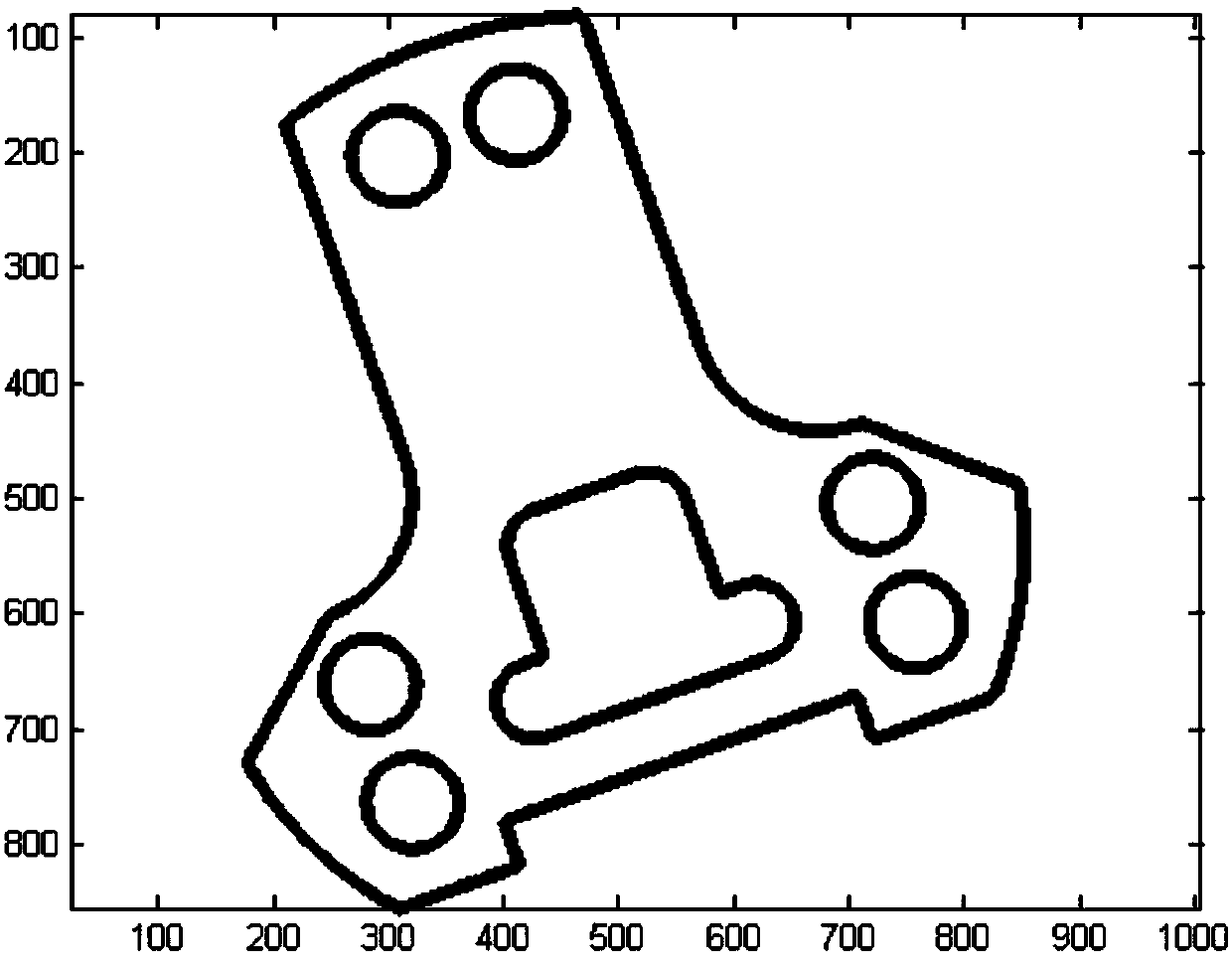

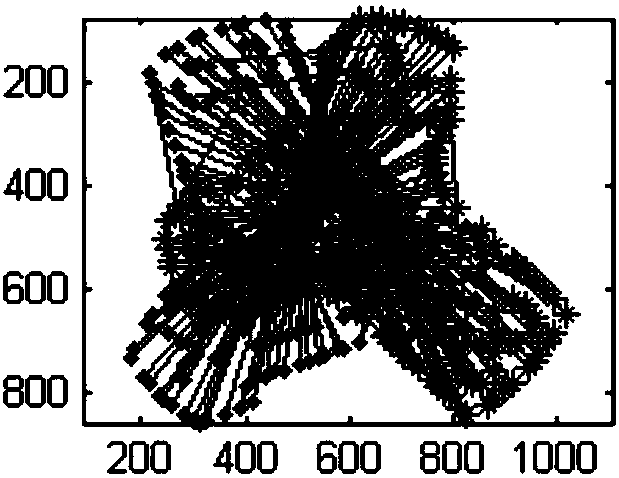

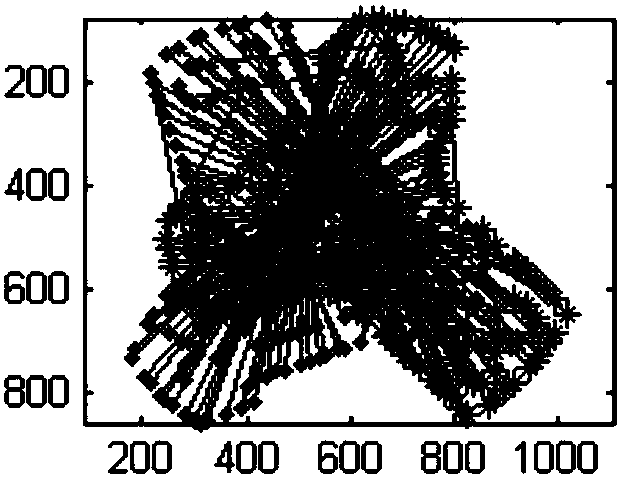

[0058] This embodiment proposes a contour vision detection algorithm, which can be divided into three steps: contour extraction, contour matching, and error calculation. First, the area where the workpiece is located is extracted on the image, the noise is removed, the contour is closed, and the edge extraction algorithm based on the local area is used to extract the sub-pixel edge. Then, a coarse-to-fine matching strategy is used for contour matching. Take sample points first, calculate the shape context features for preliminary contour registration, and use the iterative closest point algorithm for precise matching to ensure the accuracy and efficiency of contour matching. Finally, the error of each position is calculated according to the result of contour matching.

[0059] The specific steps of a contour vision detection algorithm proposed in this embodiment are as follows:

[0060] Step S1. Use an industrial camera to collect the image of the detected workpiece, extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com