Concentric double-layer energy-saving quick heating type electromagnetic induction heating unit

A technology of electromagnetic induction heating and electromagnetic induction coil, which is applied to liquid heating. , In the field of electromagnetic induction heating body, it can solve the problems of large electromagnetic radiation, low heat exchange efficiency and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

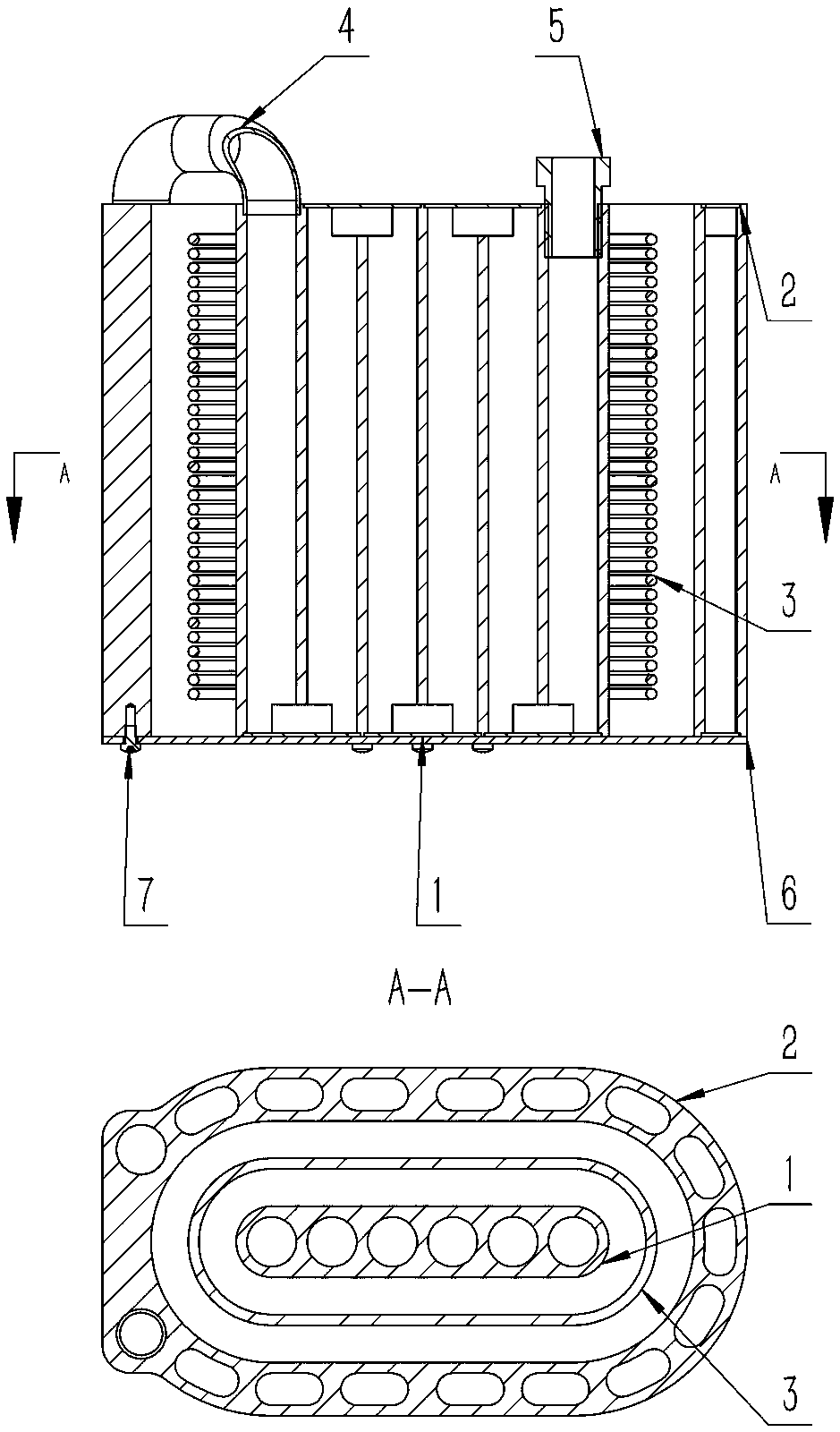

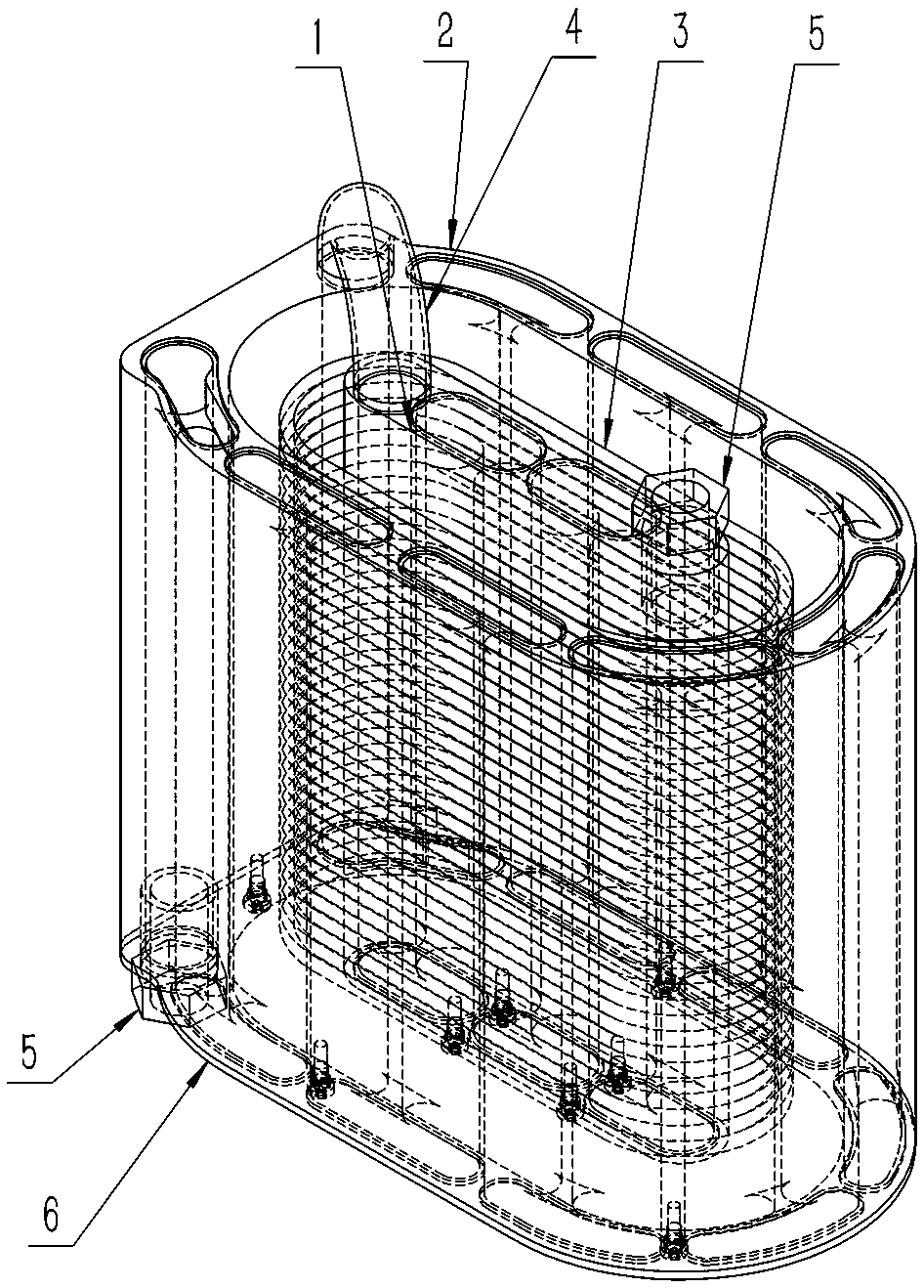

[0014] Embodiment 1, as attached figure 1 And attached figure 2 , a concentric double-layer energy-saving fast-heating electromagnetic induction heating body, which is mainly composed of a core heating body 1, an outer heating body 2, a high-temperature resistant electromagnetic induction coil 3, a connecting pipe 4, an electromagnetic shielding connecting plate 6 and an insulated high-temperature resistant water pipe joint 5 and so on. In order to further reduce the local heat dissipation of the heating body and reduce the impact on the electrical components of the integrated heater, heat insulation materials are wrapped on the outside of the heating body during application. This example needs to use a small pipeline pump to make the water or liquid with a certain pressure enter the outer heating body 2 from the bottom insulating high-temperature resistant water pipe joint 5, pass through multiple round-trip U-shaped channels, enter the core heating body 1 through the conne...

Embodiment 2

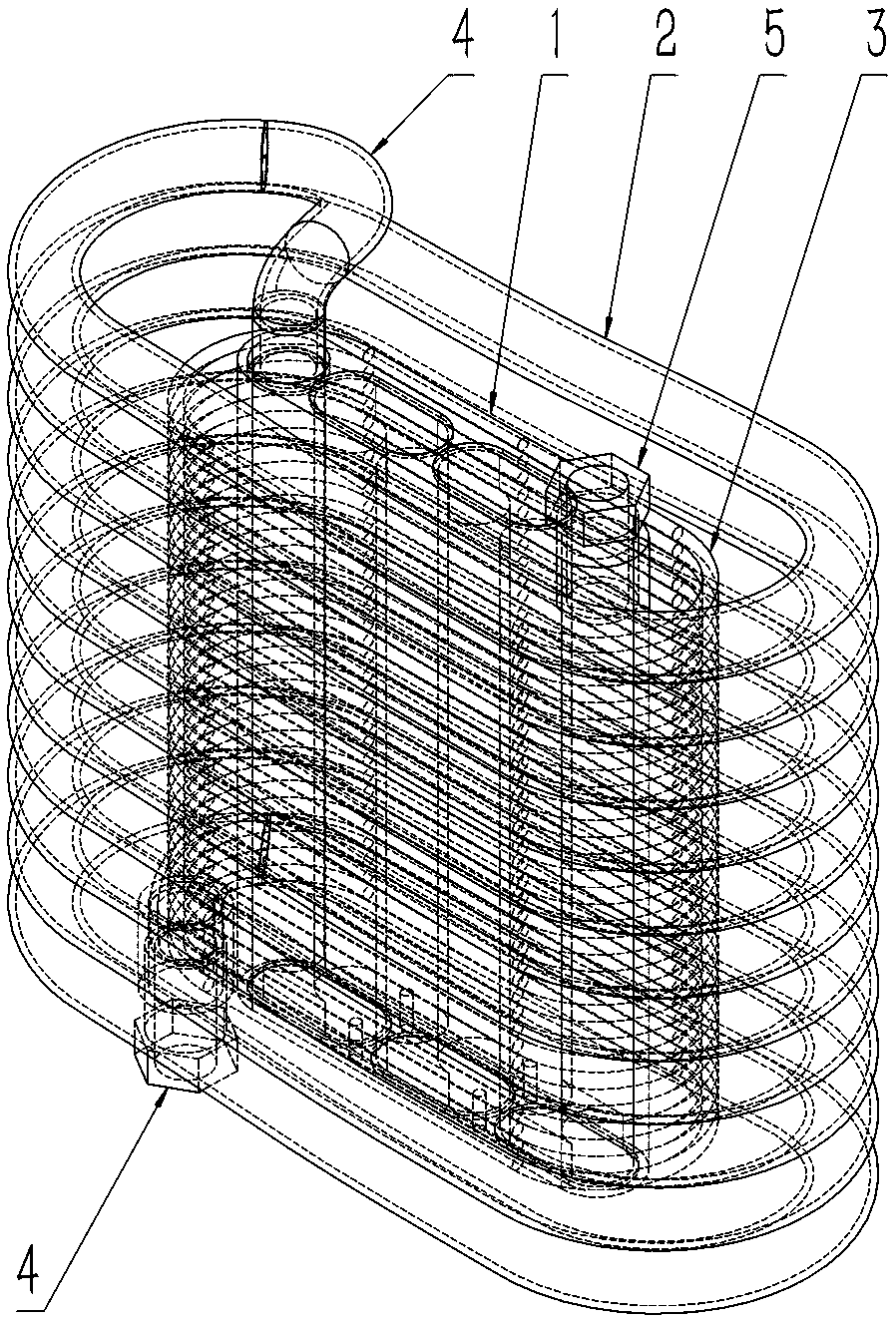

[0015] Embodiment 2, as attached image 3 , and the structure and composition of Example 1 are basically the same, and the outer heating body 2 adopts the form of a profiling spiral coil, which is made of round tubes, square tubes, and rectangular tubes. The connecting pipe 4 and the electromagnetic shielding connecting plate 6 follow the outer heating body 2 and the core heating body to change corresponding shapes and sizes, and their functions remain unchanged. An imitation steel shield is installed on the outer side of the spiral tube of the outer heating body 2, which fully shields electromagnetic waves and seals the heat of the heating body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com