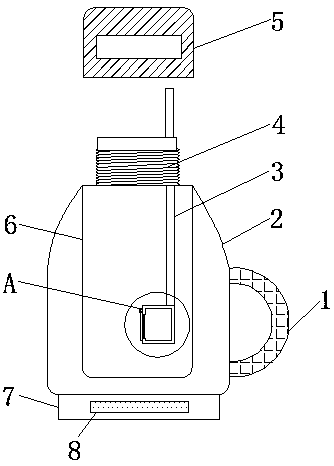

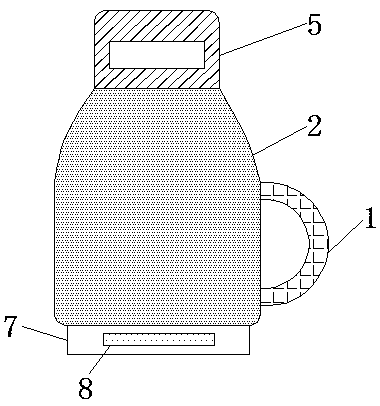

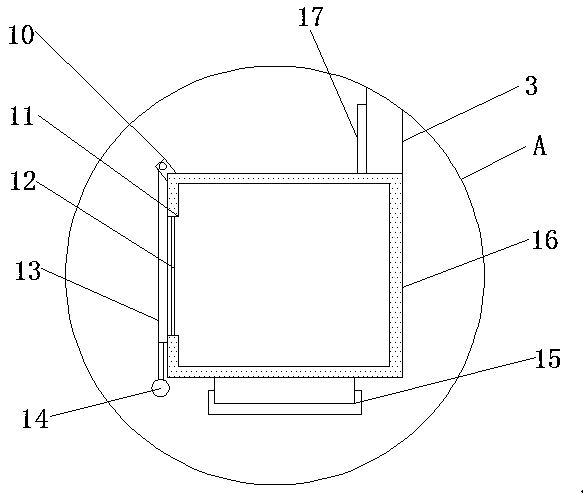

Durable wear-resistant heat insulation kettle

A thermal insulation pot and anti-wear technology, which is applied to household containers and other directions, can solve the problems that the thermal insulation pot is not suitable for making tea, affects the taste, and the thermal insulation pot does not have the function of a mobile phone holder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing an insulating liner, the method comprising the following steps:

[0027] Weigh 28 parts of Fe-MOF@Al 2 o 3 Nanomaterials, 56 parts of phenolic resin, 8 parts of calcium stearate, 0.5 part of fatty alcohol polyether, 3 parts of lignocellulose, and 3 parts of polydimethylsiloxane, each raw material weighed above is added to the premixer Under normal temperature, stir at a speed of 150r / min for 60min. After stirring, check whether the slurry is evenly stirred. If not, continue to stir according to the above stirring time and speed until uniform, and finally obtain the thermal insulation spray coating;

[0028] Step 2. Clean the surface of the inner tank body to ensure that there is no visible grease and dirt, and remove the high points on the surface to avoid stress concentration during the coating film formation process. For the parts with serious surface corrosion, after anti-rust treatment, In order to carry out the next step of spraying;

[00...

Embodiment 2

[0037] Step 1. Weigh 18 parts of Fe-MOF@Al 2 o 3 Nanomaterials, 26 parts of phenolic resin, 8 parts of calcium stearate, 0.5 part of fatty alcohol polyether, 3 parts of lignocellulose, and 3 parts of polydimethylsiloxane, each raw material weighed above is added to the premixer Under normal temperature, stir at a speed of 150r / min for 60min. After stirring, check whether the slurry is evenly stirred. If not, continue to stir according to the above stirring time and speed until uniform, and finally obtain the thermal insulation spray coating; the rest Preparation is the same as in Example 1.

Embodiment 3

[0039] Step 1. Weigh 30 parts of Fe-MOF@Al 2 o 3 Nanomaterials, 16 parts of phenolic resin, 8 parts of calcium stearate, 0.5 parts of fatty alcohol polyether, 3 parts of lignocellulose, and 3 parts of polydimethylsiloxane, each raw material weighed above is added to the premixer Under normal temperature, stir at a speed of 150r / min for 60min. After stirring, check whether the slurry is evenly stirred. If not, continue to stir according to the above stirring time and speed until uniform, and finally obtain the thermal insulation spray coating; the rest Preparation is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com