Preparation method of wide-temperature-region type rubber damping material

A technology of damping materials and wide temperature range, which is applied in the field of rubber materials, can solve the problems of damping performance degradation, easy migration, high price, etc., and achieve the effect of improving damping wide range, wide damping temperature range and improving damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

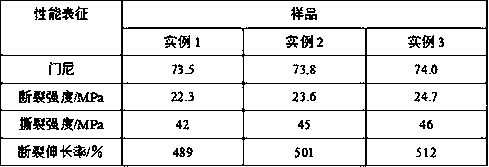

Examples

example 1

[0021] In terms of parts by weight, weigh 12 parts of Eucommia leaves, 7 parts of Panax notoginseng leaves, and 47 parts of asparagus asparagus, stir and mix them, and vacuum freeze-dry them for 4 hours to obtain a dried product and grind it through an 80-mesh sieve to obtain a ground powder. 1:3, stir and mix the grinding powder and 15% sodium carbonate solution by mass fraction, heat to boiling and heat preservation for 2 hours, let it stand and cool to room temperature, filter to obtain the filtrate, and rotary evaporate at 67°C to 1 / 3 of the volume of the filtrate. The concentrated solution was obtained, and the concentrated solution was mixed with absolute ethanol at a volume ratio of 1:5. After standing and aging for h, the filter cake was filtered and collected, and dried at 67°C for 7 hours to prepare dry agar gel; in parts by weight Count, weigh 47 parts of deionized water, 12 parts of dry agar, and 4 parts of diethylaminoethyl cellulose respectively in a flask, stir a...

example 2

[0023] In terms of parts by weight, weigh 10 parts of Eucommia leaves, 5 parts of Panax notoginseng leaves, and 45 parts of asparagus asparagus, stir and mix them, and vacuum freeze-dry them for 3 hours. 1:3, stir and mix the grinding powder with 15% sodium carbonate solution by mass fraction, heat to boil and then heat-preserve for 1h, let it stand and cool to room temperature, filter to obtain the filtrate, and rotary evaporate at 65°C to 1 / 3 of the volume of the filtrate. The concentrated solution was obtained and the concentrated solution was mixed with absolute ethanol at a volume ratio of 1:5. After standing and aging for 6 hours, the filter cake was filtered and collected, and dried at 65°C for 6 hours to prepare dry agar; in parts by weight Count, weigh 45 parts of deionized water, 10 parts of dry agar, and 3 parts of diethylaminoethyl cellulose, respectively, and place them in a flask, stir and mix and ultrasonically disperse to obtain a dispersion and heat it in a wat...

example 3

[0025] In terms of parts by weight, weigh 15 parts of Eucommia leaves, 8 parts of Panax notoginseng leaves, and 50 parts of asparagus asparagus, stir and mix them, and vacuum freeze-dry them for 5 hours. 1:3, stir and mix the grinding powder and 15% sodium carbonate solution by mass fraction, heat to boiling and heat preservation for 2 hours, let it stand and cool to room temperature, filter to obtain the filtrate, and rotary evaporate at 70°C to 1 / 3 of the volume of the filtrate. The concentrated solution was obtained, and the concentrated solution was mixed with absolute ethanol at a volume ratio of 1:5. After standing and aging for h, the filter cake was filtered and collected, and dried at 70°C for 8 hours to prepare dry agar; in parts by weight Count, weigh 50 parts of deionized water, 15 parts of dry agar and 5 parts of diethylaminoethyl cellulose respectively in a flask, stir and mix and ultrasonically disperse to obtain a dispersion and heat it in a water bath at 85°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com