Dendritic polyurethane, preparation method thereof and application of dendritic polyurethane in chlorinated butyl damping rubber

A polyurethane and dendritic technology, applied in the field of damping materials, can solve the problems of insufficient damping performance, poor mechanical performance, and insufficient effective damping temperature range, and achieve increased hydrogen bonding, mechanical properties and thermal conductivity. The effect of improved damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of dendritic polyurethane comprises the following steps:

[0042] TEA-TL: Dissolve 1.788g (0.012mol, 1eq) of triethanolamine in anhydrous ethyl acetate, add 5.6628g of α-cyano-γ-thiolactone (0.0396mol, each equivalent of hydroxyl corresponds to 1.1 equivalents of isocyanate groups), Add 4-5 drops of DBTL after blowing nitrogen to exhaust oxygen, then raise the temperature to 70°C, and react for 24 hours. The reaction mixture was precipitated with n-hexane, the viscous mixture was dissolved in ethyl acetate and then precipitated with glacial ether, and dried in a vacuum oven at 60°C to obtain a yellow viscous substance.

[0043] Synthesis of G1: 1.734g of G0-TL (0.003mol, 1eq) was dissolved in 10ml of chloroform, 3.375g of 3-amino-1-propanol (5eq / TL functional group, 15eq in total) and 10.44g of acrylic acid-2- Hydroxyethyl ester (10eq / TL functional group, 30eq in total), reacted for 12h. After the reaction was completed, it was precipitated with...

Embodiment 1

[0062] Add 100g of chlorinated butyl rubber, 1g of stearic acid, 5g of nano-zinc oxide, 1.5g of accelerator M, 2g of anti-aging agent A, 0.15g of light magnesium oxide, 1g of coordinated G2-Py and 1g of sulfur according to the above ratio In the open mill, kneading is carried out under the condition that the temperature of the roller is 30° C., so as to obtain the damping rubber of the present invention.

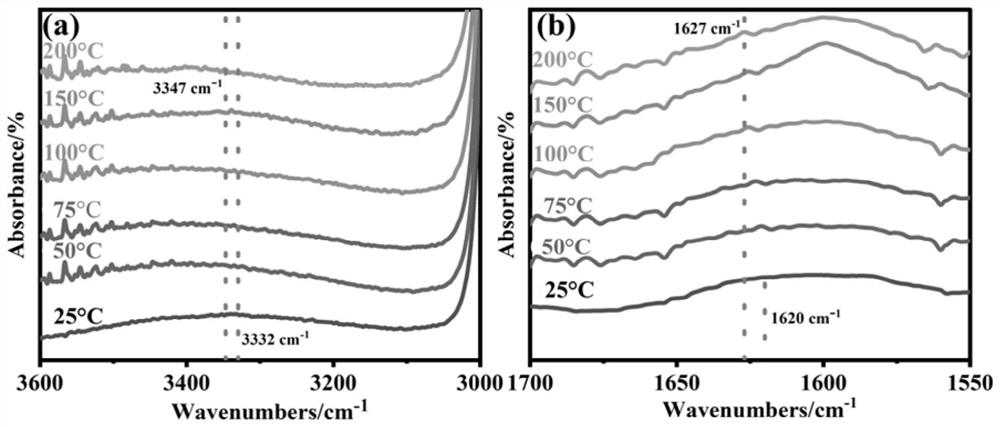

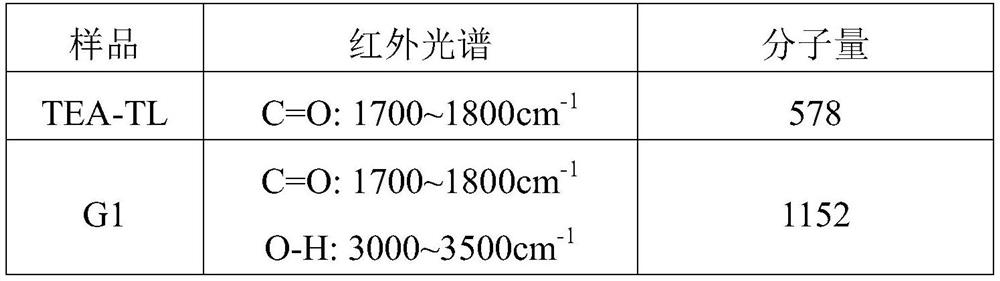

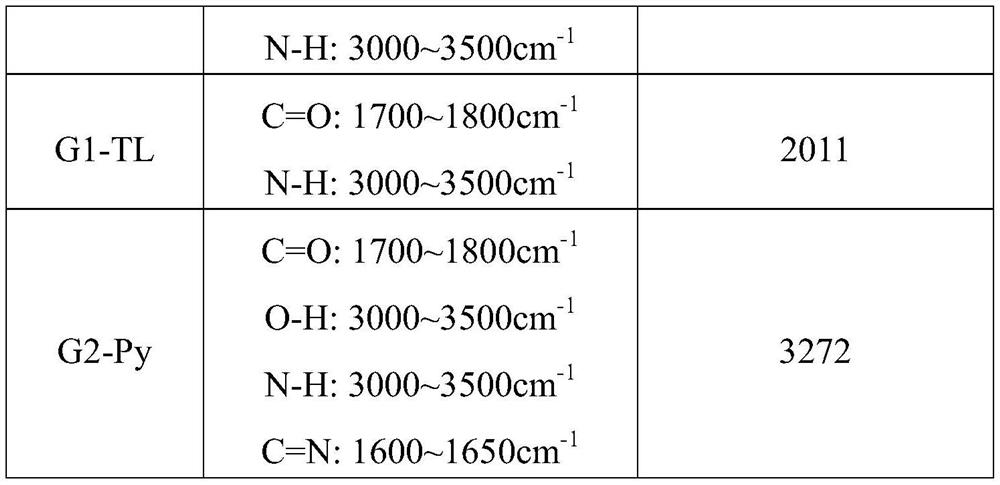

[0063] The infrared spectrum and molecular weight of each step of dendritic polyurethane are shown in Table 1. The loss factor, tensile strength, elongation at break and thermal conductivity of G2-Py damping rubber are shown in Table 2.

Embodiment 2

[0065] Add 100g of chlorinated butyl rubber, 1g of stearic acid, 5g of nano-zinc oxide, 1.5g of accelerator M, 2g of anti-aging agent A, 0.15g of light magnesium oxide, 3g of coordinated G2-Py and 1g of sulfur according to the above ratio In the open mill, kneading is carried out under the condition that the temperature of the roller is 30° C., so as to obtain the damping rubber of the present invention.

[0066] The infrared spectrum and molecular weight of each step of dendritic polyurethane are shown in Table 1. The loss factor, tensile strength, elongation at break and thermal conductivity of G2-Py damping rubber are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com