Spherical aluminum nitride-expanded graphite reinforced high-thermal-conductivity PP/PA6 composite material and preparation method thereof

A technology of expanded graphite and composite materials, which is applied in the field of spherical aluminum nitride-expanded graphite reinforced high thermal conductivity PP/PA6 composite materials and its preparation, can solve the problems of high cost, narrow application range, mechanical strength and durability of PBT and PPS plastics. The temperature capacity cannot meet the demand and other problems, and achieve the effects of low cost, wide application range, improved mechanical properties and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also discloses a method for preparing the above-mentioned spherical aluminum nitride-expanded graphite reinforced high thermal conductivity PP / PA6 composite material, comprising the following steps:

[0032] (1) Take PA6 resin, PP resin, expanded graphite, spherical aluminum nitride, compatibilizer and antioxidant of described weight part respectively, stand-by;

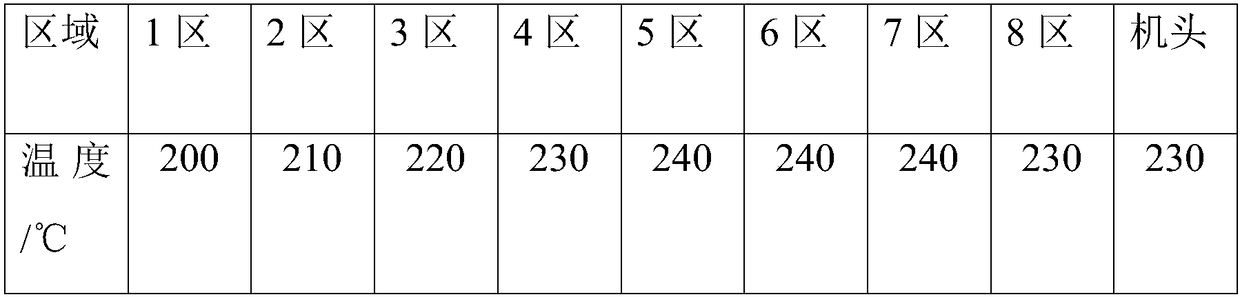

[0033] (2) Add PA6 resin, expanded graphite and spherical aluminum nitride to the twin-screw extruder, and melt and extrude to obtain premix one; add PP resin, compatibilizer and antioxidant to the twin-screw extruder In the machine, melt extrusion to obtain premix two;

[0034] (3) Add the premix 1 and the premix 2 into a twin-screw extruder, and melt extrude to obtain the high thermal conductivity PP / PA6 composite material; the screw speed is 350r / min , the temperature is 200°C-240°C.

[0035] PP material is widely used due to its advantages of low cost, light weight, and easy process...

Embodiment 1

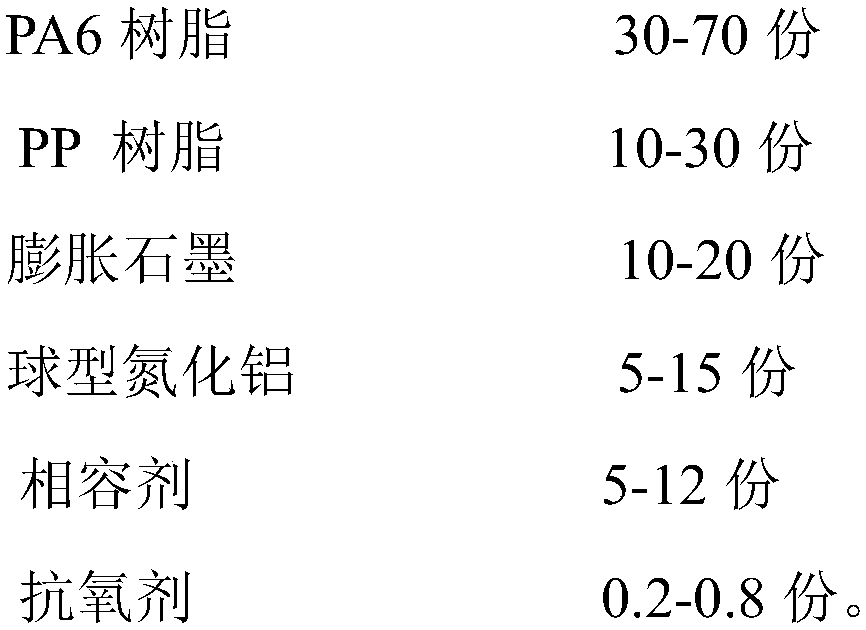

[0041] The high thermal conductivity PP / PA6 composite material of the present embodiment is made of raw materials comprising the following parts by weight:

[0042]

[0043] Among them, the thermally conductive filler includes 15 parts of expanded graphite and 10 parts of spherical aluminum nitride, the particle sizes of which are 1250 mesh and 250 mesh respectively; the compatibilizer is 3 parts of maleic anhydride grafted polypropylene and 2 parts of SEBS grafted maleic acid A blend of anhydride copolymers; the antioxidant is a blend of 0.3 parts of Antioxidant 1010 and 0.5 parts of Antioxidant 168.

[0044]The preparation method of a kind of spherical aluminum nitride-expanded graphite reinforced high thermal conductivity PP / PA6 composite material of embodiment 1 comprises the following steps:

[0045] (1) Add the weighed PA6 resin, expanded graphite and spherical aluminum nitride into the twin-screw extruder, and melt and extrude to obtain premix one; and the weighed PP...

Embodiment 2

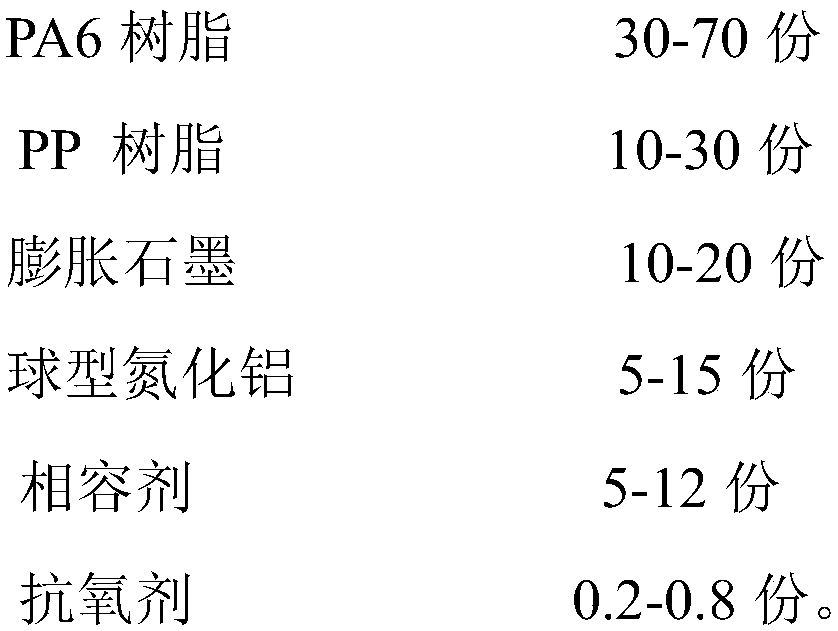

[0048] The high thermal conductivity PP / PA6 composite material of the present embodiment is made of raw materials comprising the following parts by weight:

[0049]

[0050] Among them, the thermally conductive filler includes 5 parts of expanded graphite and 20 parts of spherical aluminum nitride, the particle sizes of which are 1250 mesh and 250 mesh respectively; the compatibilizer is 3 parts of maleic anhydride grafted polypropylene and 2 parts of SEBS grafted maleic acid A blend of anhydride copolymers; the antioxidant is a blend of 0.3 parts of Antioxidant 1010 and 0.5 parts of Antioxidant 168.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com