Graphene-containing heat conducting polyimide film and preparation method thereof

A technology of polyimide film and polyimide resin, which is applied in the field of preparation of graphene heat-conducting polyimide film, can solve the problem of poor applicability, small addition amount, decreased elastic modulus and tensile strength, etc. problems, to achieve the effect of increasing thermal conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

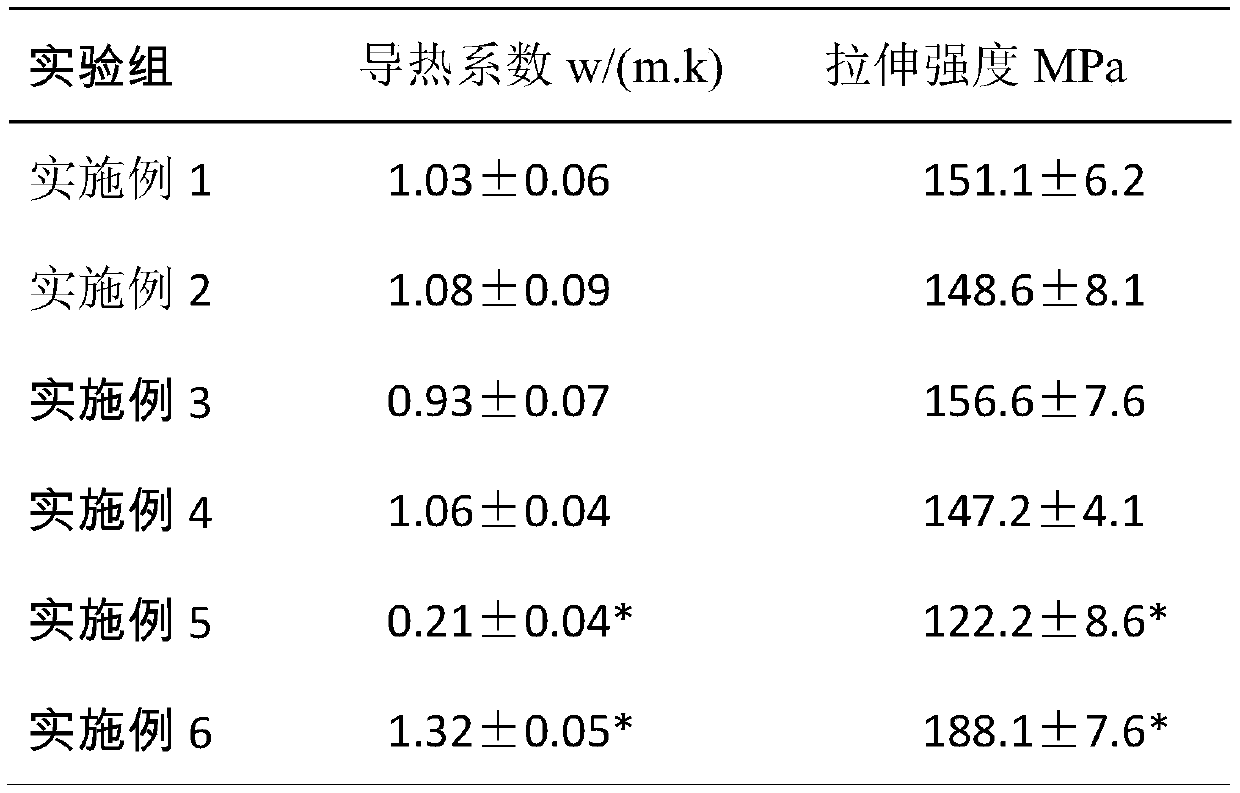

Examples

Embodiment 1

[0030] A kind of preparation method of graphene thermally conductive polyimide film is carried out according to the following steps:

[0031] (1) At room temperature, add 4,4'-diaminodiphenyl ether and pyromellitic dianhydride into the reaction kettle, add m-cresol under nitrogen protection, stir well, add isoquinoline, and heat up to 200°C , reacted for 12 hours, poured the reaction solution into ethanol to precipitate after cooling, and made polyimide resin;

[0032] (2) Put the modified graphene in dimethylacetamide, add a silane coupling agent, pre-disperse after high-temperature treatment in a high-shear disperser, and the treatment temperature is 400 ° C;

[0033] The preparation method of described modified graphene is as follows:

[0034] 1) Get 200m L of DMF and pour it into a round bottom flask, add 15g CaH thereto 2 Stir and dry for 22 hours, carry out vacuum vacuum distillation, and then save the DMF obtained through vacuum distillation for later use;

[0035] 2...

Embodiment 2

[0046] A kind of preparation method of graphene thermally conductive polyimide film is carried out according to the following steps:

[0047] (1) At room temperature, add 4,4'-diaminobenzenemethane and 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl to the reaction kettle, and add dimethylformaldehyde under nitrogen protection Amide, after stirring evenly, add isoquinoline, heat up to 180°C, react for 11 hours, after cooling, pour the reaction solution into ethanol to precipitate, and make polyimide resin;

[0048] (2) Put the modified graphene in dimethyl sulfoxide, add titanate, pre-disperse after high-temperature treatment in a high-shear disperser, and the treatment temperature is 330 ° C;

[0049] Described modified graphene, its preparation method is as follows:

[0050] 1) Get 200m L of DMF and pour it into a round bottom flask, add 15g CaH thereto 2 Stir and dry for 18 hours, carry out vacuum vacuum distillation, and then save the DMF obtained through vacuum distillatio...

Embodiment 3

[0062] A kind of preparation method of graphene thermally conductive polyimide film is carried out according to the following steps:

[0063] (1) At room temperature, 1,5-bis(4-amino-2-trifluoromethylphenoxy)naphthalene and 3,3'4,4'-benzophenone tetracarboxylic dianhydride were added to the reaction Kettle, add N-methylpyrrolidone under the protection of nitrogen, after stirring evenly, add isoquinoline, heat up to 200 ° C, react for 13 hours, after cooling, pour the reaction solution into ethanol to precipitate, and make polyimide resin;

[0064] (2) Put the modified graphene in dimethylacetamide, add isopropyl triisostearyl titanate, pre-disperse after high-temperature treatment in a high-shear disperser, and the treatment temperature is 500 ° C;

[0065] The preparation method of described modified graphene is as follows:

[0066] 1) Get 200m L of DMF and pour it into a round bottom flask, add 15g CaH thereto 2 Stirring and drying for 25 hours, vacuum distillation under r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com