Preparation method for multilayer carbon nano tube/copper composite strip

A technology of multi-layer carbon nanotubes and composite strips, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as uneven microstructure, and achieve high effective deformation efficiency, large size, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

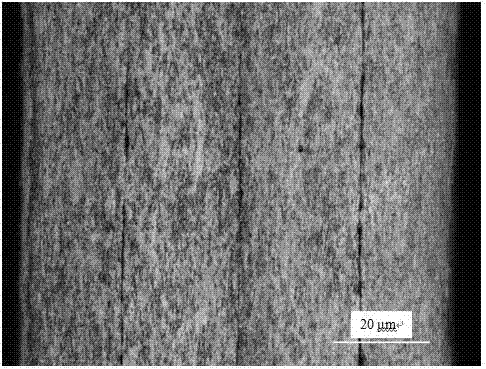

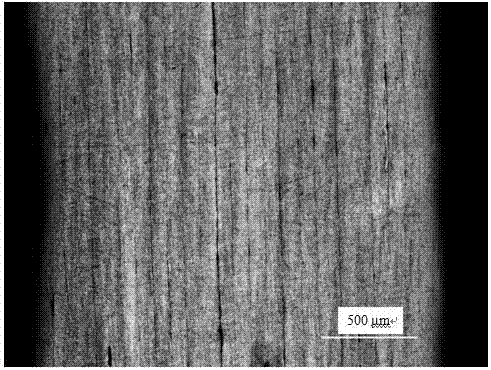

[0025] Embodiment 1: a kind of preparation method of multilayer carbon nanotube / copper composite strip is characterized in that, concrete steps are:

[0026] (1) Put the industrial pure copper (T2) strip with a thickness of 0.1mm and a width of 60mm in a hydrochloric acid solution for 5 minutes, wherein the concentration of the hydrochloric acid solution is 6mol / L, wash and air-dry;

[0027] (2) The product obtained in step (1) is subjected to surface grinding pretreatment, so that the oxide layer on the surface of the pure copper strip is peeled off, exposing the metal structure body;

[0028] (3) uniformly coating the carbon nanotube powder on the surface of the pretreated product obtained in step (2), wherein the coating thickness of the carbon nanotube is 5 μm, and drying to obtain the carbon nanotube / copper strip;

[0029] (4) Stack the carbon nanotube / copper strip obtained in step (3), and rivet after stacking so that the surface coated with the carbon nanotube is closel...

Embodiment 2

[0032] Embodiment 2: a kind of preparation method of multilayer carbon nanotube / copper composite strip is characterized in that, concrete steps are:

[0033] (1) Put the CuZn40 (H62) copper alloy strip with a thickness of 1 mm and a width of 100 mm in a hydrochloric acid solution for 15 minutes, wherein the concentration of the hydrochloric acid solution is 9 mol / L, wash and air-dry;

[0034] (2) Perform surface grinding pretreatment on the product obtained in step (1) to peel off the oxide layer on the surface of the CuZn40 (H62) copper alloy strip, exposing the metal structure body;

[0035] (3) Evenly coat the carbon nanotube coating on the surface of the pretreated product obtained in step (2), wherein the carbon nanotube coating is a mixture of carbon nanotubes and ethanol, the coating thickness of the carbon nanotubes is 10 μm, and drying to obtain carbon nanotubes Nanotube / CuZn40 (H62) copper alloy strip;

[0036] (4) Stack the carbon nanotube / CuZn40 (H62) copper alloy...

Embodiment 3

[0039] Embodiment 3: a kind of preparation method of multilayer carbon nanotube / copper composite strip is characterized in that, concrete steps are:

[0040] (1) Put the CuSn4 copper alloy strip with a thickness of 2mm and a width of 10mm in a hydrochloric acid solution for 15 minutes, wherein the concentration of the hydrochloric acid solution is 12mol / L, wash it, and air-dry it;

[0041] (2) Perform surface grinding pretreatment on the product obtained in step (1), so that the oxide layer on the surface of the CuSn4 copper alloy strip is peeled off, exposing the metal structure body;

[0042] (3) Evenly coat the carbon nanotube coating on the surface of the pretreated product obtained in step (2), wherein the carbon nanotube coating is a mixture of carbon nanotubes and ethanol, the coating thickness of the carbon nanotubes is 20 μm, and drying to obtain carbon nanotubes Nanotube / CuSn4 copper alloy strip;

[0043] (4) The carbon nanotube / CuSn4 copper alloy strips obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com