Separating-connecting type safety anti-theft lock

A clutch-type, anti-theft lock technology, applied in the field of locks, can solve problems such as inability to provide security, achieve high anti-theft safety performance, improve life, and avoid damage and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

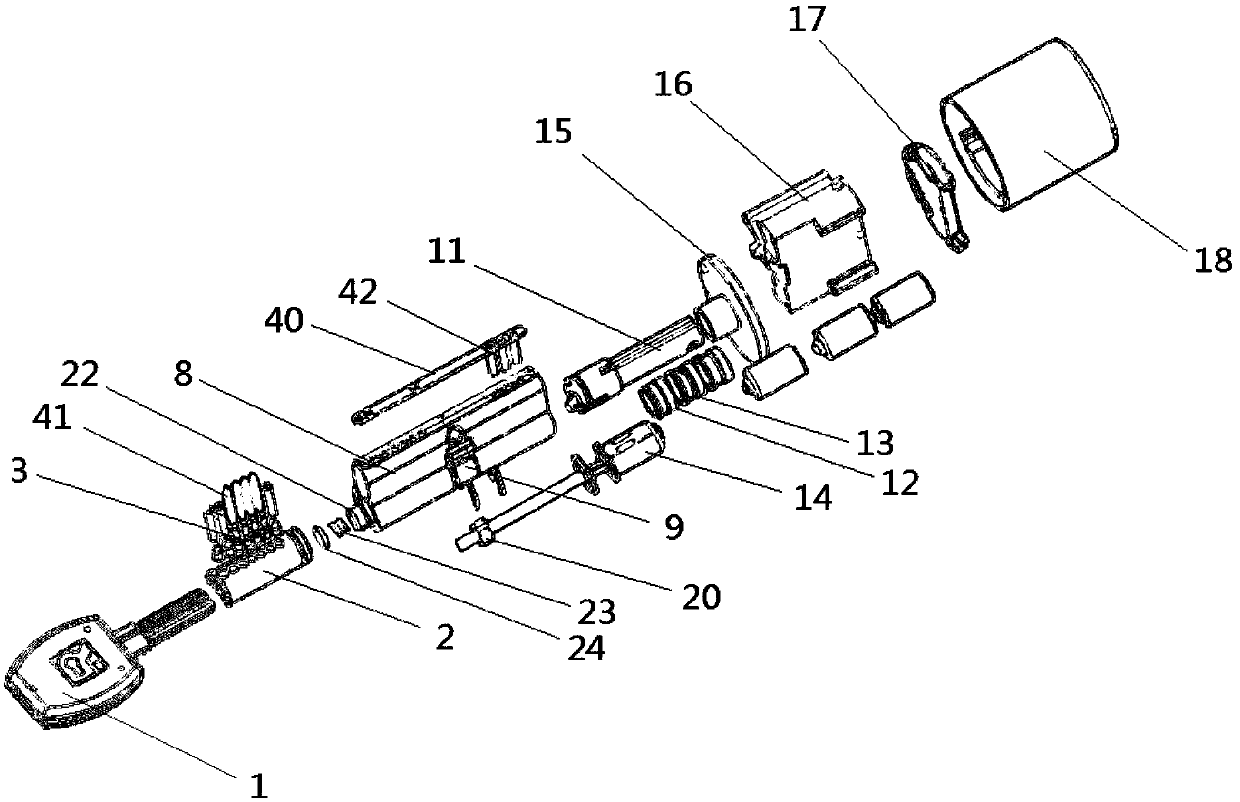

[0033] refer to figure 1 , Clutch-type security anti-theft lock, including a key 1 and a lock body 8, the lock body 8 is provided with a lock cylinder 2 and a deadbolt shift block 9, both of which are separate structures. The opening and closing of the lockset is realized after the dead bolt shifting block 9 is dialed forward or backward. The left side of deadbolt shifting block 9 is lock core 2, and the right side is provided with knob shaft 11, and knob shaft 11 and dead bolt shifting block 9 joint shafts rotate, and knob shaft 11 connects the knob handle that is positioned at the right side of lock body 8, twists The knob handle drives the deadbolt shifting block 9 to rotate through the knob shaft 11, so as to realize the effect of opening the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com