Subway axle box bearing

A technology for axle box bearings and subways, applied in the direction of shafts and bearings, bearing components, roller bearings, etc., can solve the problems of falling off, bearing damage, loose rivets, etc., achieve high processing accuracy, small space occupation, increase length and quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

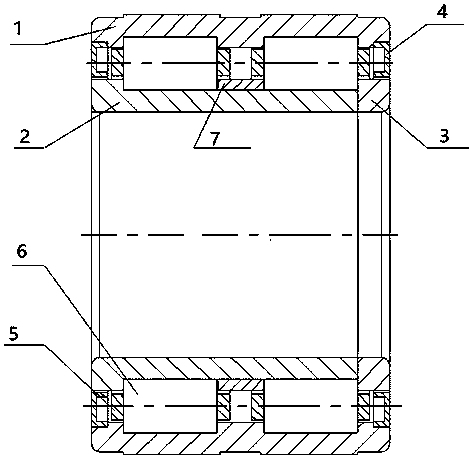

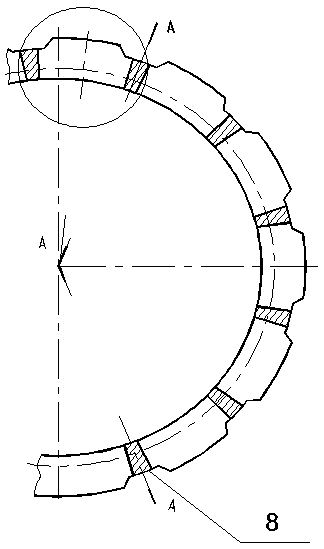

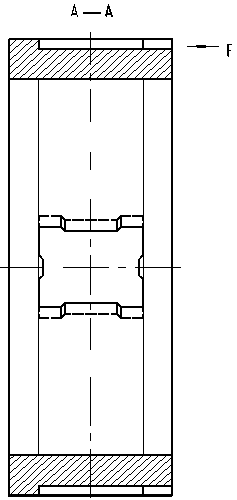

[0027] A subway axle box bearing, which consists of an outer ring 1, an inner ring 2, an inner retaining ring 3, two rows of rollers, two integral structure cages 5, two sealing rings 4 and a movable inner spacer ring 7 , the outer ring 1 has double raceways, the inner ring 2 is a single raceway, the inner spacer 3 is barrel-shaped, the outer ring 1 is installed on the outside of the inner ring 2, and the double roller of the outer ring 1 The track corresponds to the single raceway of the inner ring 2, one side of the inner ring 2 is connected to the inner retaining ring 3, and an integral structure cage 5 is installed on each of the double raceways of the outer ring 1, and the rollers are pre-loaded into the cage Among them, the movable inner spacer ring 7 is installed in the middle of the two integral structure cages 5, and the sealing ring 4 is installed in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com