Insertion type pattern projection lamp

A projection lamp, plug-in technology, applied in the cooling/heating device of lighting device, lighting and heating equipment, semiconductor device of light-emitting element, etc., can solve the problems of non-single pattern, good high temperature resistance, etc. , good high temperature resistance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

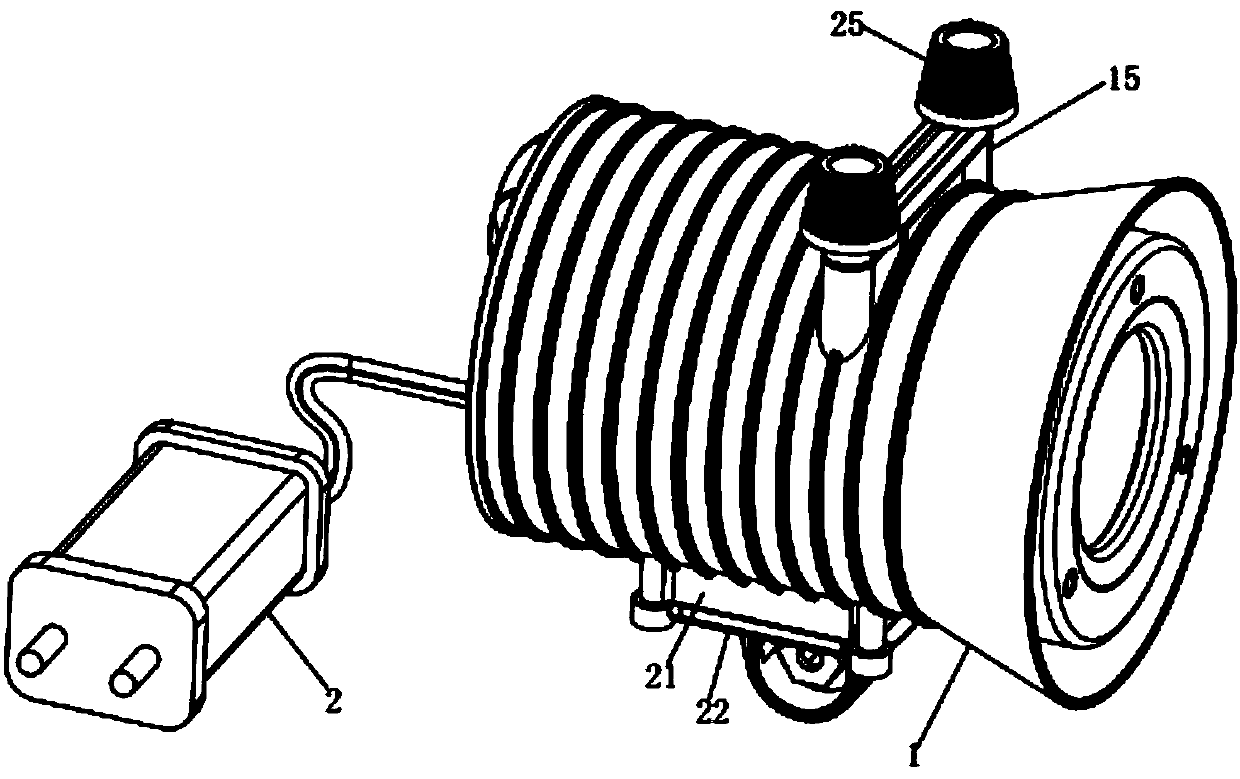

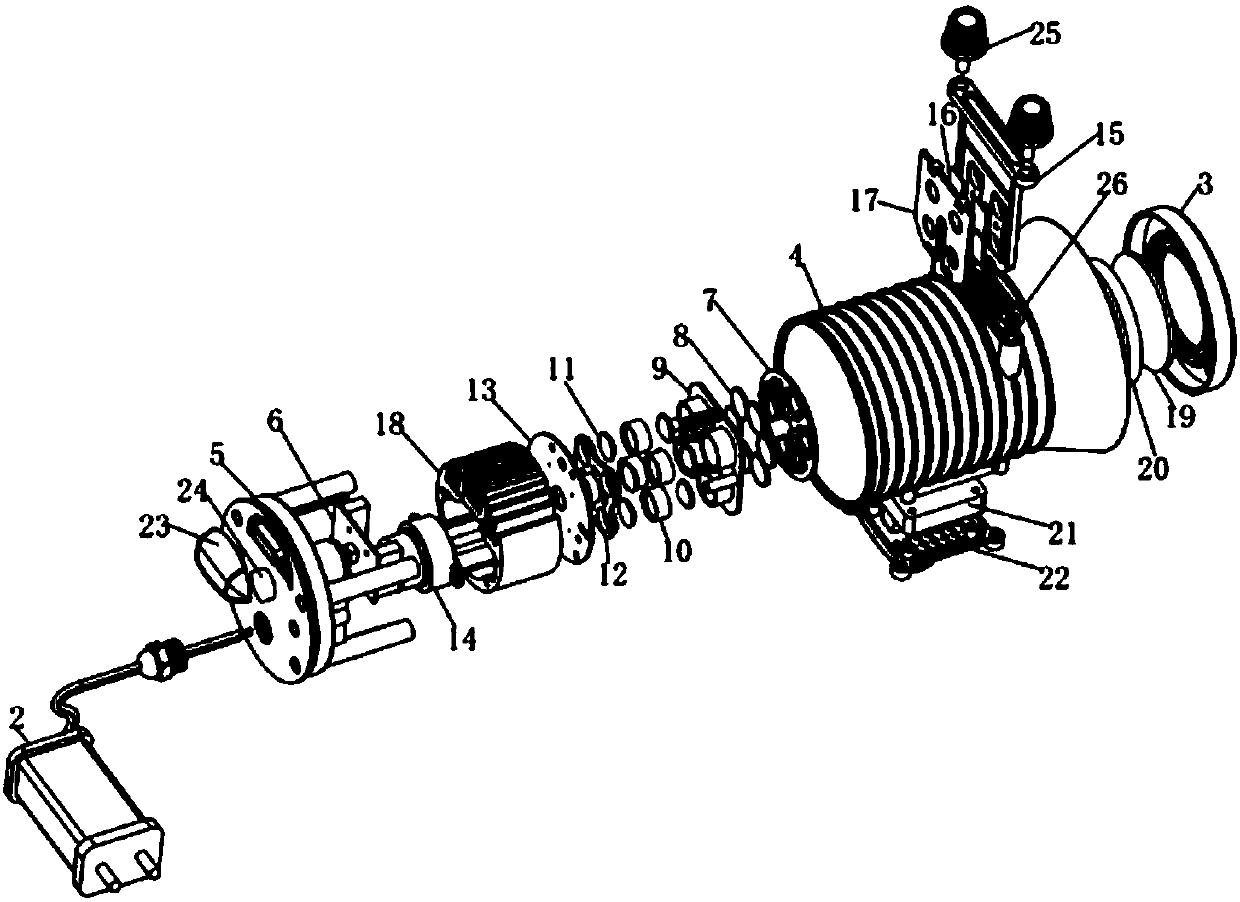

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

[0017] like Figure 1 to Figure 2 As shown, a plug-in pattern projection lamp includes a lamp body 1 and an adapter 2. The lamp body 1 is composed of a front lamp cover 3, a lamp body 4 and a rear lamp cover 5, and the rear lamp cover 5 is provided with PCB board 6, the PCB board 6 is electrically connected to the adapter 2, and the lamp body 4 is provided with an imaging lens holder 7, an imaging lens 8, a lens holder 9, a support column 10, a plano-convex lens 11, a lens pressing plate 12, and an LED assembly 13 and a motor 14, the motor 14 and the LED assembly 13 are both electrically connected to the PCB board 6, and the motor 14 is located at the rear side of the LED assembly 13, and the lens pressing plate 12 is located at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com