Switching power supply module and packaging method thereof

A technology of switching power supply and switching power supply chip, which is applied in the direction of transformer/inductor coil/winding/connection, circuit, electrical components, etc. It can solve the problem of large packaging area, large power inductor, and reducing the overall power density of switching power supply modules, etc. problem, to achieve the effect of high power density, good electrical performance, and high power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

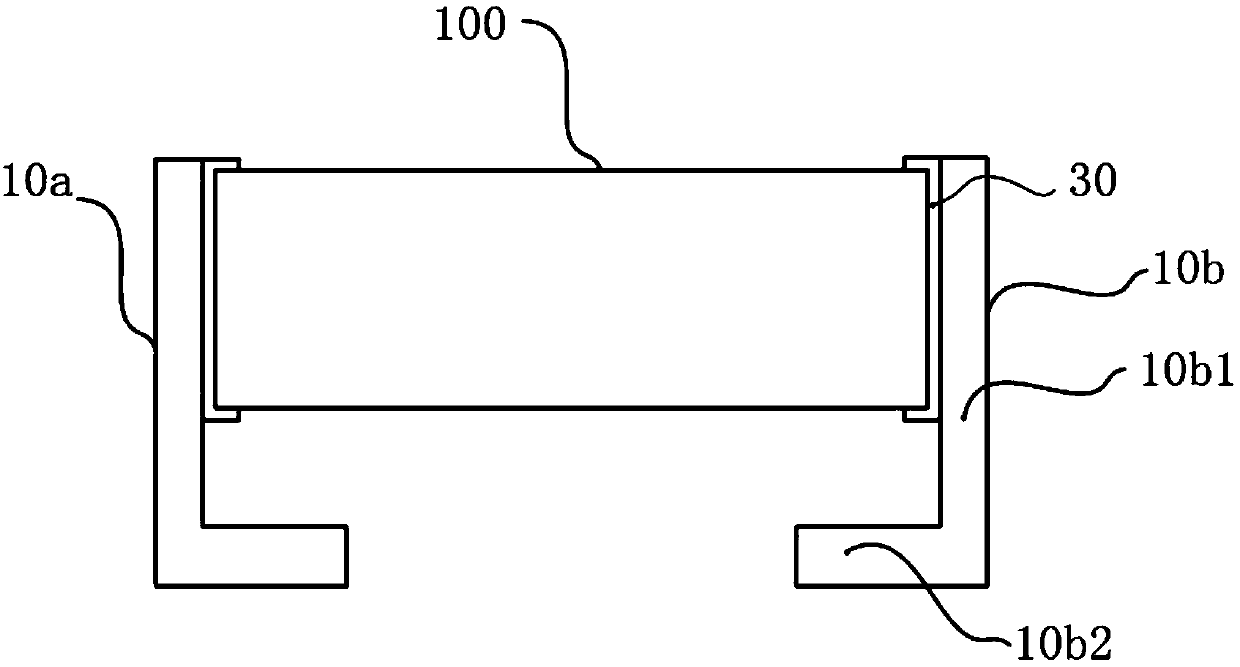

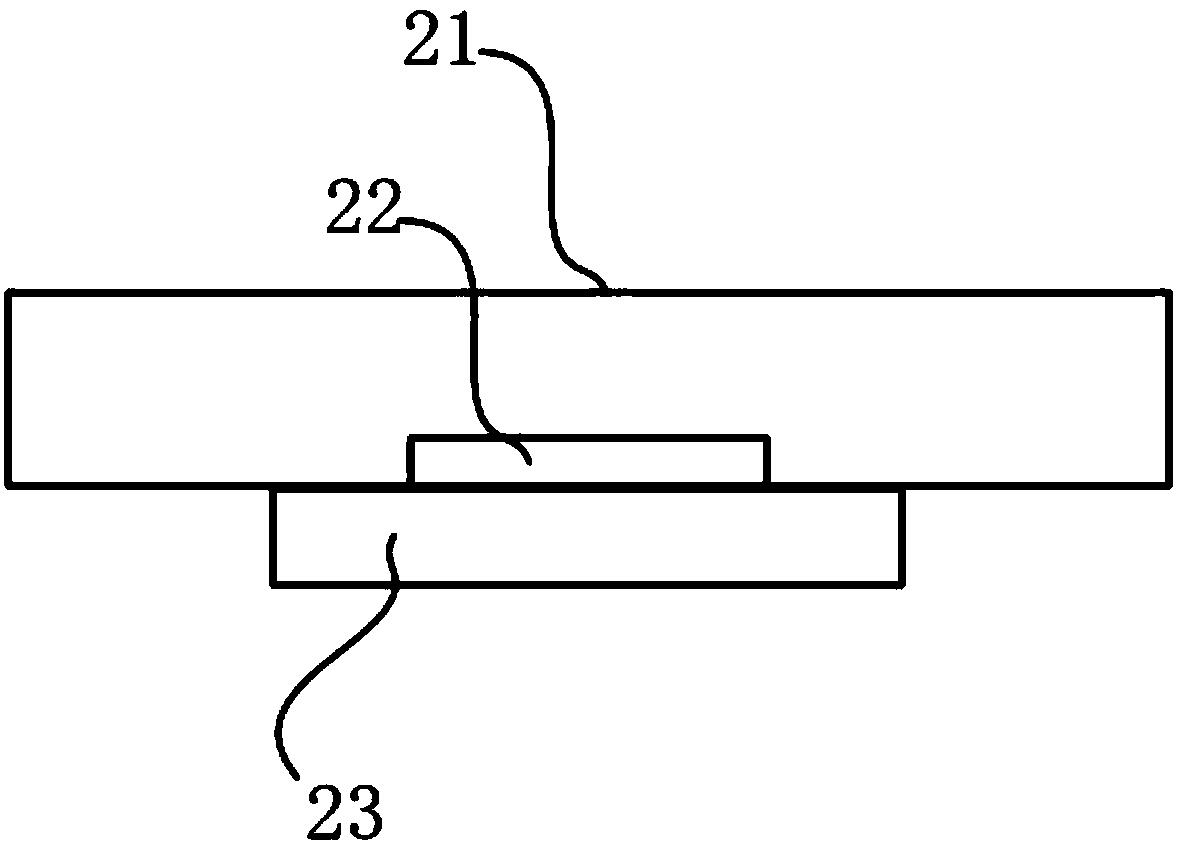

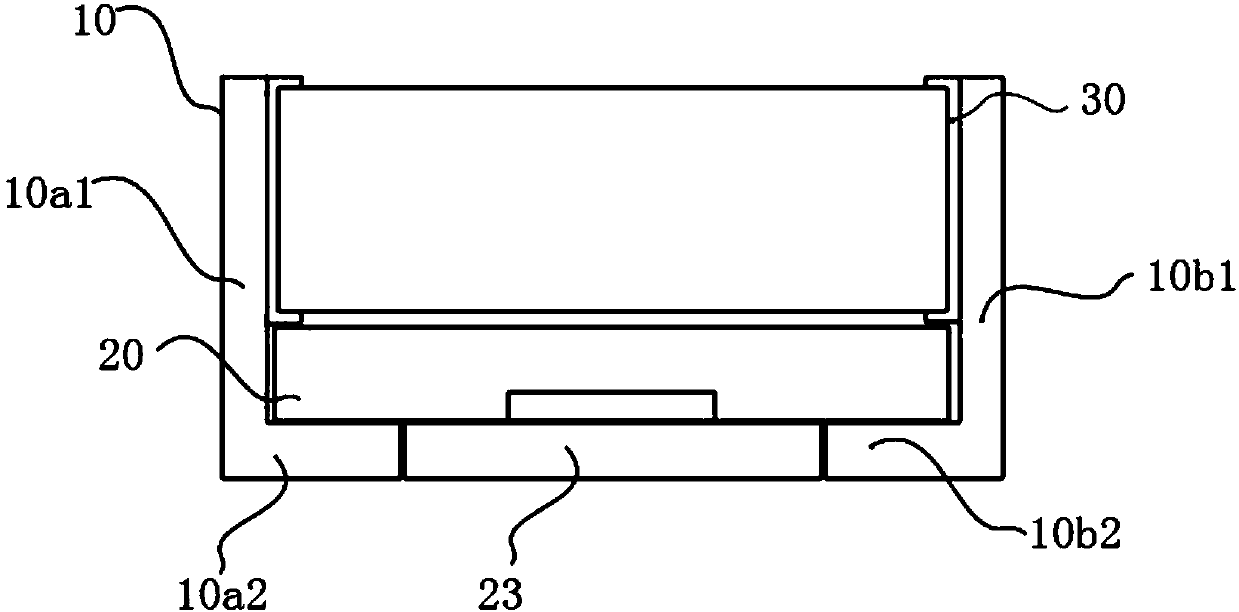

[0018] The specific embodiment of the present invention provides an integrated package switching power supply module, such as image 3 As shown, the switching power supply module includes a power inductor 10 and a switching power supply chip 20 . like figure 1 As shown, the power inductor 10 includes a magnetic core 100 and L-shaped metal terminal electrodes 10a, 10b welded to both ends of the magnetic core 100; figure 2 As shown, the switching power supply chip 20 includes a package body 21 , a bare chip 22 in the package body, and a bottom pad 23 of the bare chip. The two L-shaped metal terminal electrodes are the same, and one of them is taken as an example for illustration: the L-shaped metal terminal electrode 10b is composed of a first electrode part 10b1 and a second electrode part 10b2 perpendicular to each other, and the first elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com