Special substrate for float seedling of flue-cured tobaccos and preparation method of special substrate

A technology of floating seedling raising and flue-cured tobacco, which is applied in the direction of planting substrate, botanical equipment and methods, application, etc., can solve the problem of low root system vitality, achieve the effect of developed root system, loose substrate, and solve environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

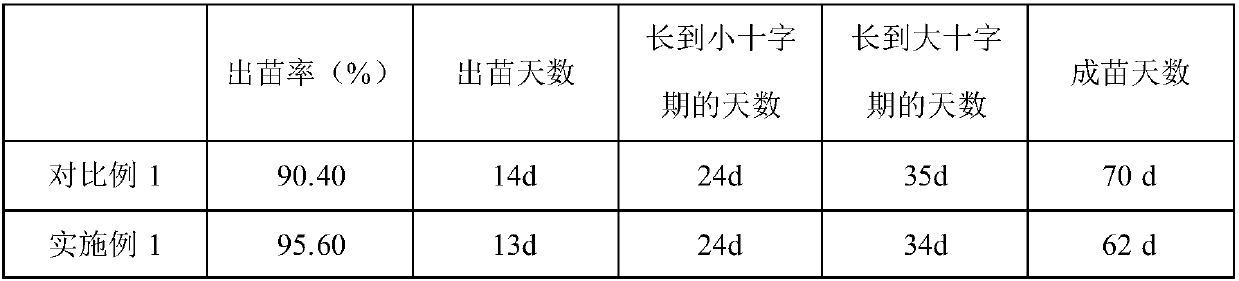

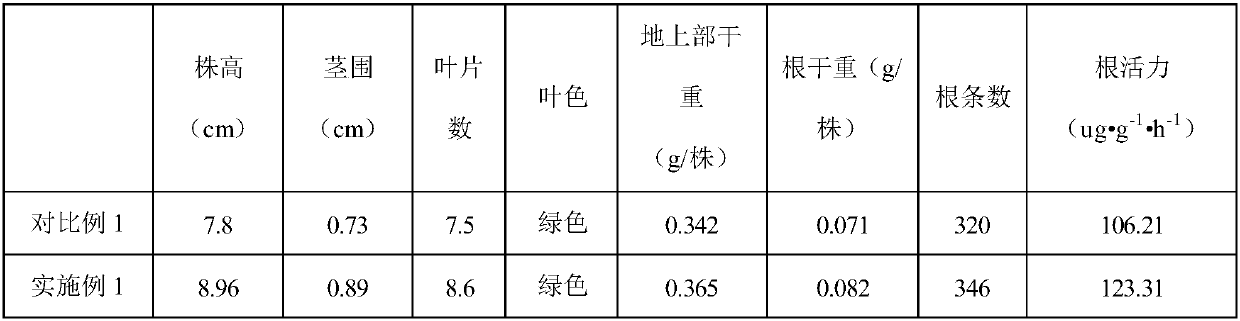

Embodiment 1

[0045] A special substrate for flue-cured tobacco floating seedlings, comprising the following components by volume:

[0046] 6.5 servings of fermented crushed corncobs

[0047] Vermiculite 1.5 parts

[0048] 1.5 parts of expanded perlite

[0049] Magangsa 0.8 parts

[0050] The preparation method of the fermented crushed corncob is as follows: first expose the corncob to the sun at 50°C, adjust the moisture content of the straw to 30%, cover with film, retting, ferment until decomposed, dry and crush to obtain the fermented crushed corncob. The pH value of the fermented crushed corncob is 6, and the particle size of the fermented crushed corncob is 1um.

[0051] According to the above components by volume, the fermented crushed corn cob, vermiculite, puffed perlite and magang sand are uniformly mixed to obtain the special substrate for floating seedling cultivation of flue-cured tobacco. The pH value of the special substrate for flue-cured tobacco floating seedlings is 5....

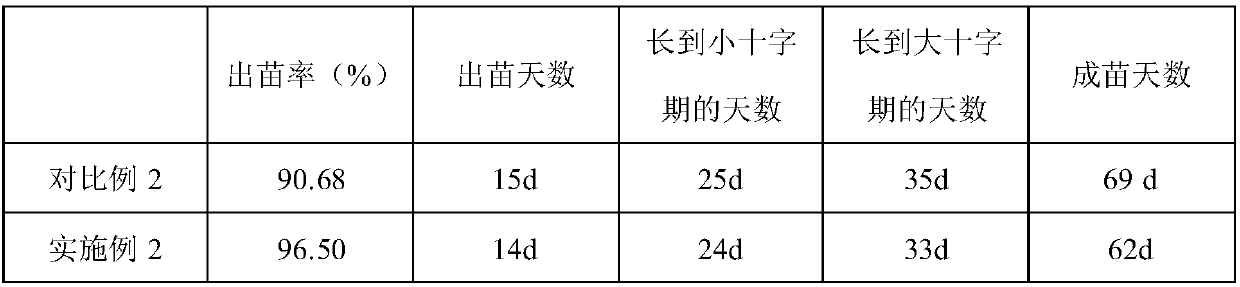

Embodiment 2

[0077] A special substrate for flue-cured tobacco floating seedlings, comprising the following components by volume:

[0078] 7 servings fermented corn cobs

[0079] 1 part vermiculite

[0080] 1 part expanded perlite

[0081] Magangsa 0.5 part.

[0082] The preparation method of the fermented crushed corn cob is as follows: first expose the corn cob to the sun at 80°C, adjust the moisture content of the straw to 40%, cover with film, retting, ferment until decomposed, dry and crush to obtain fermented crushed corn Cobs, the pH value of fermented crushed corncobs is 6.3, and the particle size of fermented crushed corncobs is 3um.

[0083] According to the above components by volume, the fermented crushed corn cob, vermiculite, puffed perlite and magang sand are uniformly mixed to obtain the special substrate for floating seedling cultivation of flue-cured tobacco. The pH value of the special substrate for flue-cured tobacco floating seedlings is 6, and the bulk density is ...

Embodiment 3

[0107] A special substrate for flue-cured tobacco floating seedlings, comprising the following components by volume:

[0108] 6 servings fermented corncobs

[0109] 2 parts vermiculite

[0110] 2 parts expanded perlite

[0111] 1 serving of Magangsa.

[0112] The preparation method of the fermented crushed corn cob is as follows: first expose the corn cob to the sun at 100°C, adjust the moisture content of the straw to 50%, cover with film, retting, ferment until decomposed, dry, and crush to obtain fermented crushed corn core. The pH value of the fermented crushed corncob is 7, and the particle size of the fermented crushed corncob is 5um.

[0113] According to the above-mentioned components by volume, after the fermented crushed corncob, vermiculite, expanded perlite and magang sand are mixed evenly, the special substrate for floating seedling cultivation of flue-cured tobacco is obtained. The pH value of the special substrate for floating seedling cultivation of flue-cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com