Production technology of capsicol

A production process, the technology of chili red, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of low added value, simple product form, difficult to store, etc., and achieve the effect of long shelf life and color improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

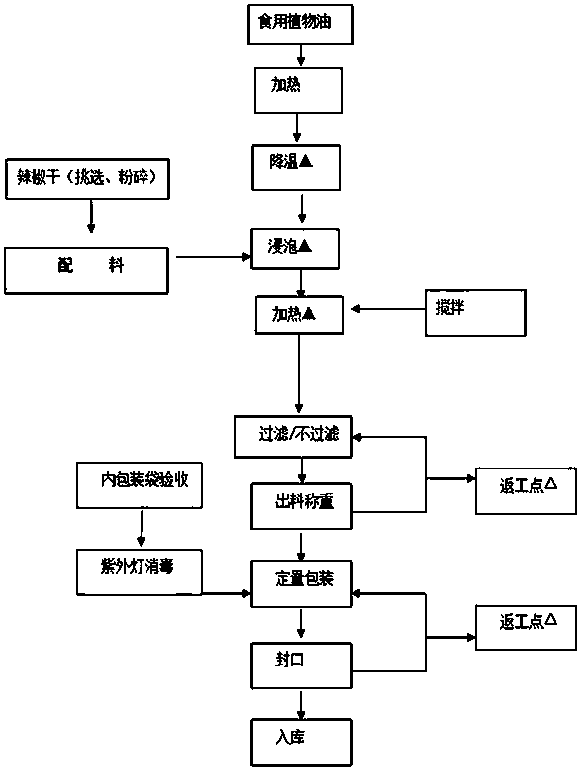

[0026] see figure 1 , in the embodiment of the present invention, capsicum red oil production process comprises the following steps:

[0027] 1) Pick the dried peppers, cut them into 2-4cm sections, separate the pepper skins from the pepper seeds, then crush the pepper skins through a 40-mesh sieve, and mix them with the pepper seeds to prepare chili powder for later use.

[0028] 2) Take edible vegetable oil, heat it to 230°C, and keep it warm at this temperature for 5 minutes, then cool down the edible oil to 78°C, and stir evenly while adding chili powder; stop heating after adding chili powder, let it cool down naturally, soak 8h, prepared chili oil; wherein the mass ratio of edible vegetable oil to chili powder was 0.8:1.

[0029] 3) After soaking, heat the chili oil to 80°C while stirring; then turn off the heat and mature for 12 hours;

[0030] 4) Weigh the cured chili oil, pack it quantitatively, seal it, and store it to get the red chili oil. The inner packaging ba...

Embodiment 2

[0032] see figure 1 , in the embodiment of the present invention, capsicum red oil production process comprises the following steps:

[0033] 1) Select the dried chili peppers, cut them into 2-4cm sections, separate the chili skin from the chili seeds, then crush the chili skin through a 100-mesh sieve, mix with the chili seeds to prepare chili powder for later use.

[0034] 2) Take edible vegetable oil, heat it to 270°C, and keep it warm at this temperature for 15 minutes, then cool down the edible oil to 85°C, and stir evenly while adding chili powder; stop heating after adding chili powder, let it cool down naturally, soak 12h, prepare chili oil; Wherein the mass ratio of edible vegetable oil and chili powder is 4:1.

[0035] 3) After soaking, heat the chili oil to 135°C while stirring; then turn off the heat and mature for 24 hours;

[0036] 4) Weigh the cured chili oil, pack it quantitatively, seal it, and store it to get the red chili oil. The inner packaging bag of q...

Embodiment 3

[0038] see figure 1 , in the embodiment of the present invention, capsicum red oil production process comprises the following steps:

[0039] 1) Select the dried chili peppers, cut them into 2-4cm sections, separate the chili skin from the chili seeds, then crush the chili skin through a 60-mesh sieve, mix with the chili seeds to prepare chili powder for later use.

[0040] 2) Take edible vegetable oil, heat it to 240°C, and keep it warm at this temperature for 8 minutes, then cool down the edible oil to 80°C, and stir evenly while adding chili powder; stop heating after adding chili powder, let it cool down naturally, soak 9h, prepare chili oil; Wherein the mass ratio of edible vegetable oil and chili powder is 1.5:1.

[0041] 3) After soaking, heat the chili oil to 85°C while stirring; then turn off the heat and mature for 14 hours;

[0042] 4) Weigh the cured chili oil, pack it quantitatively, seal it, and store it to get the red chili oil. The inner packaging bag of qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com