Waste treatment and recycle system

A technology for treating system and waste, applied in the field of waste treatment and reuse system, can solve the problems of unstable source and quality of sand and gravel, different particle size distribution and thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]In order to make those skilled in the art understand the technology, means and effects used by the present invention to achieve the purpose, a preferred embodiment will be listed below in conjunction with the drawings, and the detailed description is as follows:

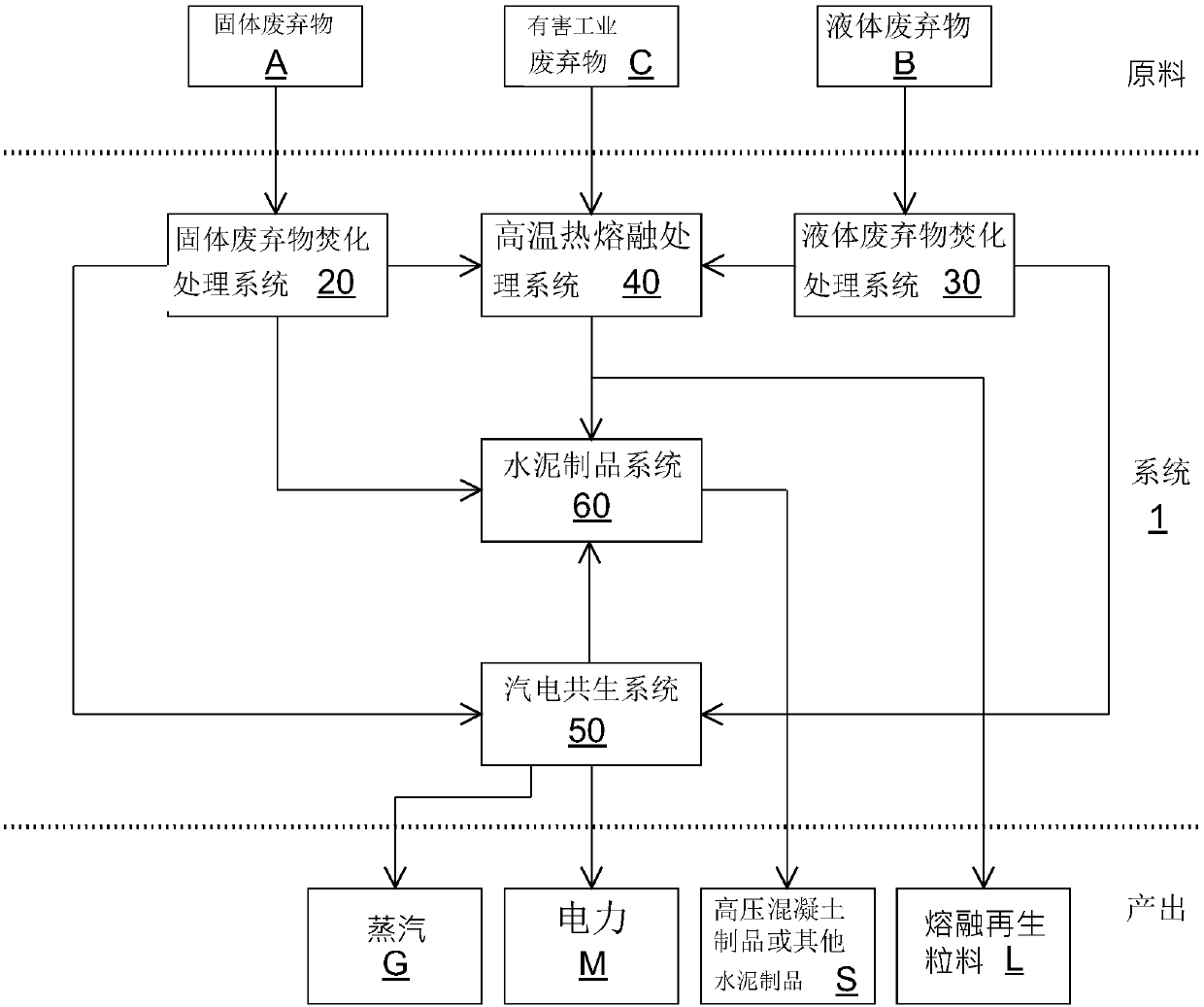

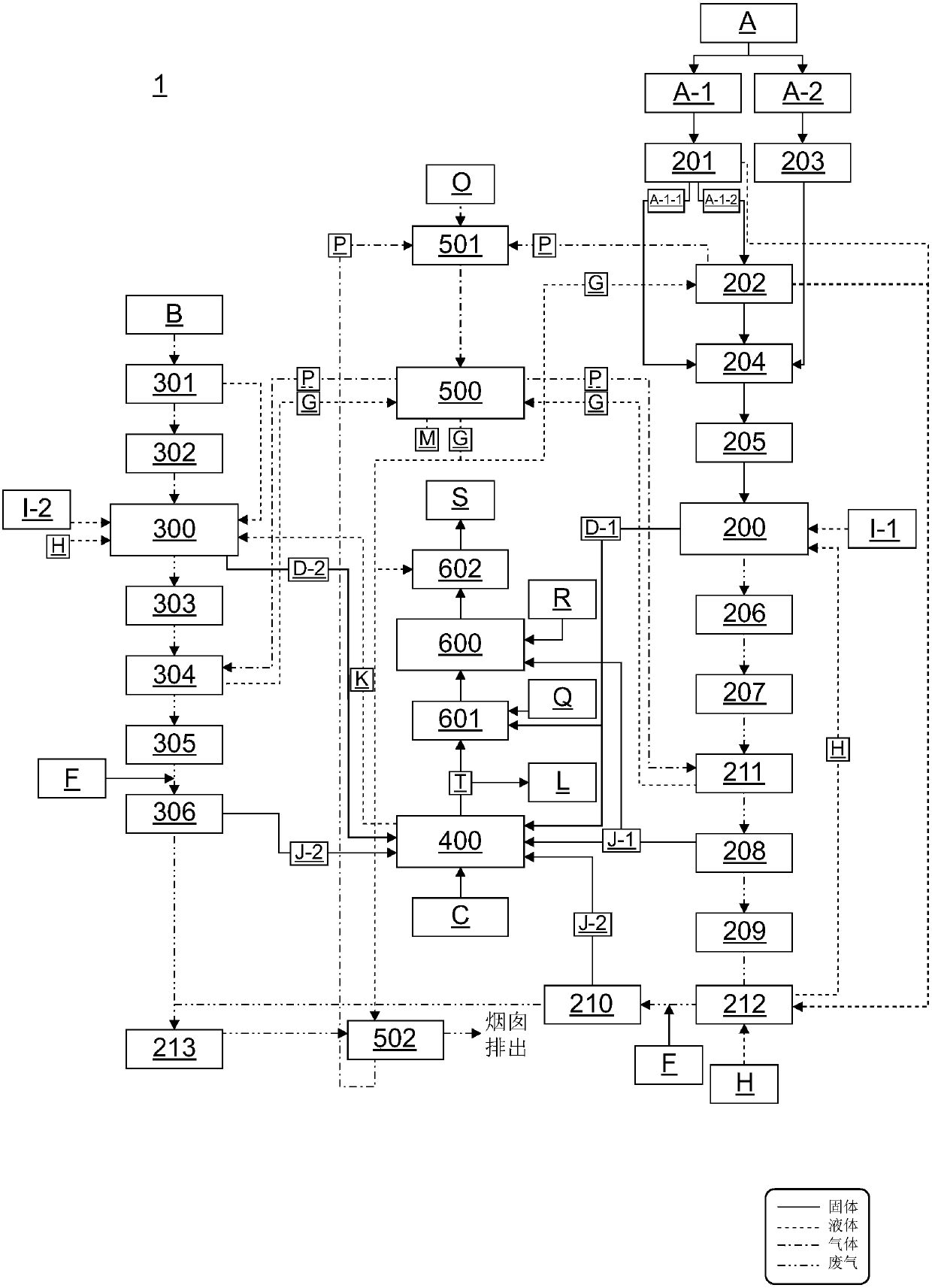

[0070] First, see figure 1 and cooperate figure 2 As shown, the waste treatment and reuse system 1 includes a solid waste incineration treatment system 20 , a liquid waste incineration treatment system 30 , a high-temperature thermal fusion treatment system 40 , a cogeneration system 50 and a cement product system 60 . In addition, the solid waste incineration treatment system 20 is used to process general industrial waste (sludge) A-1 and general industrial waste (except sludge) A-2 of solid waste A, and is connected to high-temperature thermal melting treatment System 40, steam-electric cogeneration system 50, and cement product system 60. In an embodiment of the present invention, the general industrial wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com