Numerical control four-shaft welding manipulator

A welding manipulator and robotic arm technology, applied in the field of robots, can solve problems such as inaccurate welding, difficulty in aligning the welding wire, and inability to guarantee the flatness of the welding wire, so as to achieve the effect of avoiding shaking and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

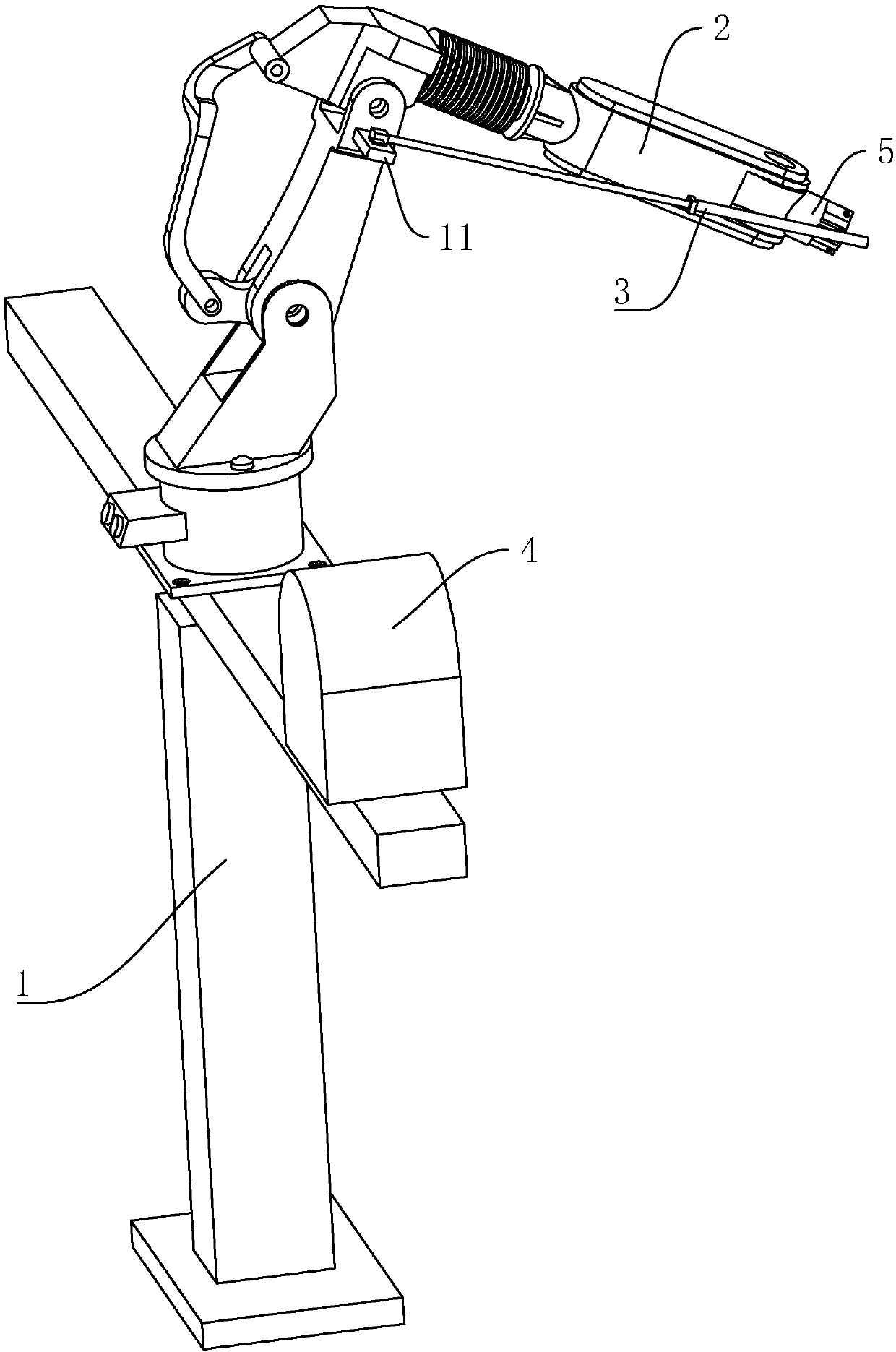

[0042] Embodiment 1, a kind of numerical control four-axis welding manipulator, such as figure 1 As shown, it includes a truss 1 for installing it at a designated position, and a robotic arm 2 is provided on the truss 1, and the robotic arm 2 can slide on the truss 1 to form a degree of freedom; the robotic arm 2 itself has three degrees of freedom , capable of rotating in three directions, thus forming a four-axis manipulator.

[0043] Such as figure 1 As shown, one side of the mechanical arm 2 is fixed with a fixed rod 11 parallel to the mechanical arm 2. The fixed rod 11 is arranged horizontally and has a welding torch 3 at its end. The opening of the welding torch 3 faces the same position as the end of the mechanical arm 2. One end of the truss 1 is provided with a welding wire winding machine 4 , in which coiled welding wire is installed. During the welding process, the welding wire winding machine 4 can provide welding wire required for welding to the welding torch 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com