Numerical control hydraulic transmission system

A hydraulic transmission and numerical control technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of wasting workshop space and energy, and achieve the effect of fast and accurate stop and saving workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

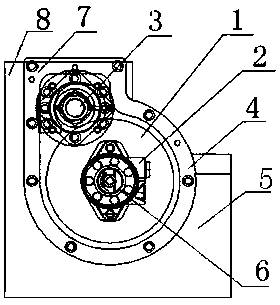

[0008] Depend on figure 1 It is known that a programmable hydraulic transmission system consists of a large gear 1, a high-sensitivity hydraulic motor 2, a servo encoder 3, a pinion 4, a screw 5, a screw slide 6, a mounting seat 7 and a dust cover 8 , the high-sensitivity hydraulic motor 2 is connected through the large gear 1, the pinion 4 and the screw 5, the high-sensitivity hydraulic motor 2 drives the large gear 1 to rotate, the pinion 4 and the screw 5 rotate accordingly, and the screw 5 is installed with a screw The slider 6 moves back and forth along the screw rod 5, the screw slider 6 is connected with a cutting tool, the screw rod 5 is movably connected to the mounting seat 7, the servo encoder 3 is installed on the tail of the screw rod 5 and the mounting seat 7, The screw 5 rotates, and the screw slider 6 moves on it. The servo encoder 3 measures the displacement according to the rotation of the screw 5. When the displacement set by the machine tool control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com