A method for in-situ weaving additive manufacturing of continuous fiber reinforced composites

A reinforced composite material and continuous fiber technology, which is applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of difficult realization of complex structures, complex processes, bonding strength between material layers, and performance anisotropy, so as to save the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

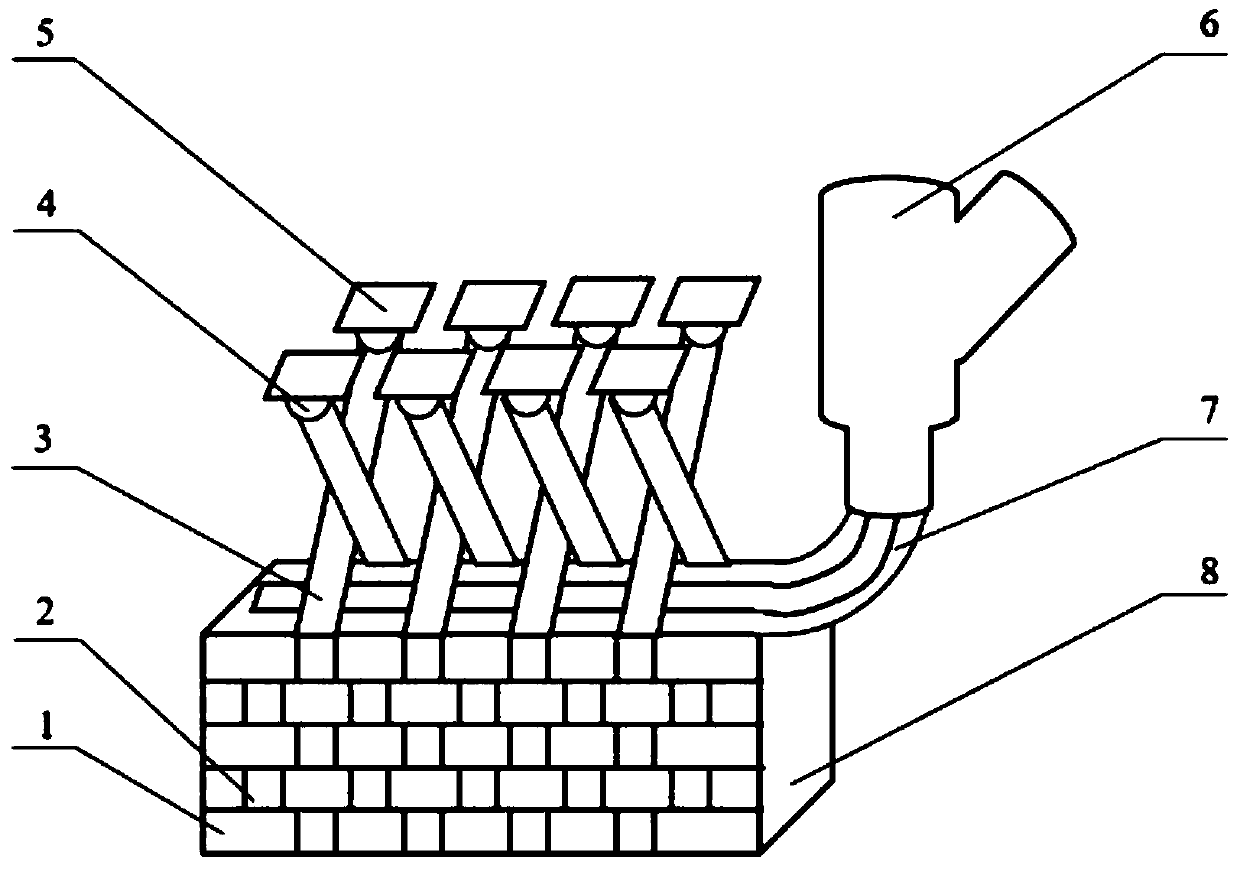

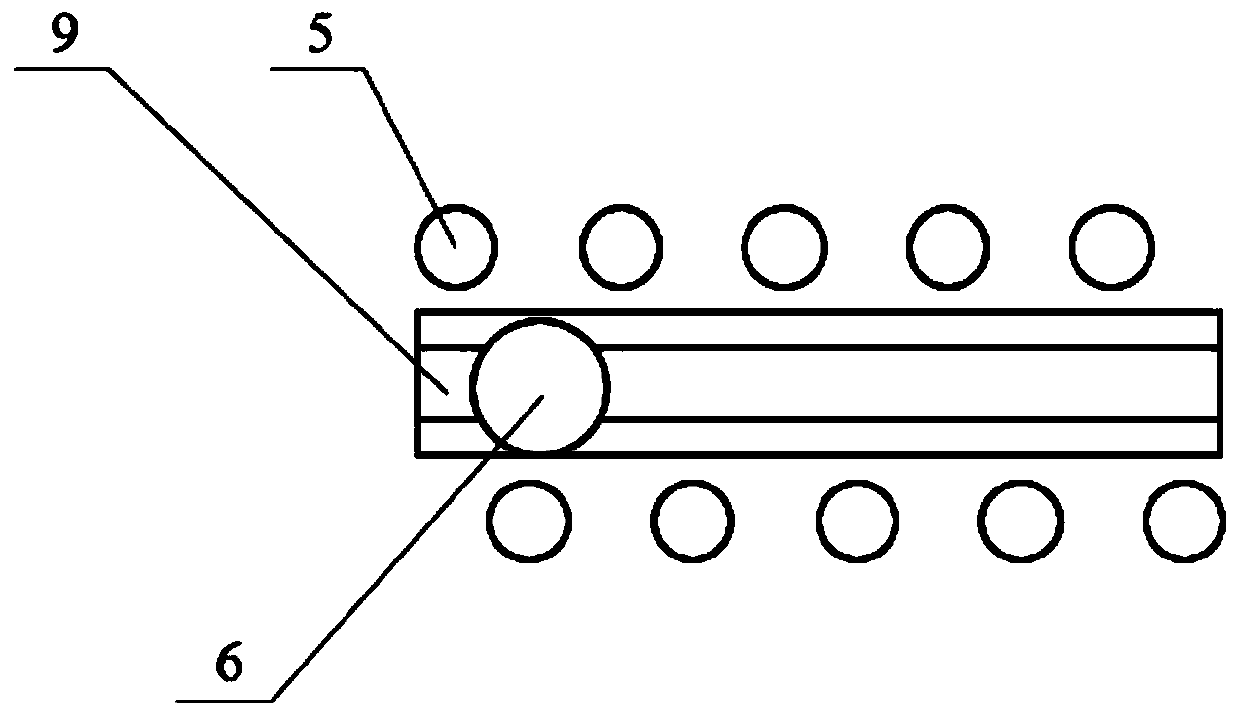

[0025] Embodiment 1, for slender thin-walled parts, refer to figure 1 , figure 2 and image 3 , an in-situ weaving additive manufacturing method for continuous fiber reinforced composites, comprising the following steps:

[0026] a) Hierarchically discretize the data of the three-dimensional component: the thin-walled part 9 to be printed is dimensioned as a thin-walled part with a length of 100mm and a height of 50mm, and the wall thickness is the width of the extruded resin under a single scanning track ; The material is PLA composite continuous carbon fiber material, and the three-dimensional data of the slender thin-walled part 9 is discretely processed by commercial software, and the path is planned and the printing parameters are formulated: the printing path is a single-track reciprocating linear scanning method, and the layer thickness is 0.5 mm(0.2mm-0.5mm), scanning distance 1.6mm(0.4mm-1.6mm), scanning speed 2mm / s(1mm / s-5mm / s), printing temperature 220℃;

[0027...

Embodiment 2

[0031] Embodiment 2, for circular thin-walled parts, refer to figure 1 and Figure 4 , an in-situ weaving additive manufacturing method for continuous fiber reinforced composites, comprising the following steps:

[0032] a) Hierarchically discretize the data of the three-dimensional component: set the size of the ring-shaped thin-walled part 10 to be printed as a thin-walled part with a diameter of 80mm and a height of 50mm, and the wall thickness is the width of the extruded resin under a single scanning track ; The material is PLA composite continuous carbon fiber material, and after the three-dimensional data of the ring-shaped thin-walled part 10 is discretely processed by commercial software, the path is planned and the printing parameters are formulated: the printing path is a single-track reciprocating linear scanning method, and the layer thickness is 0.5 mm, scanning distance 1.6mm, scanning speed 1mm / s, printing temperature 220℃;

[0033]b) Pre-grouping and pre-sha...

Embodiment 3

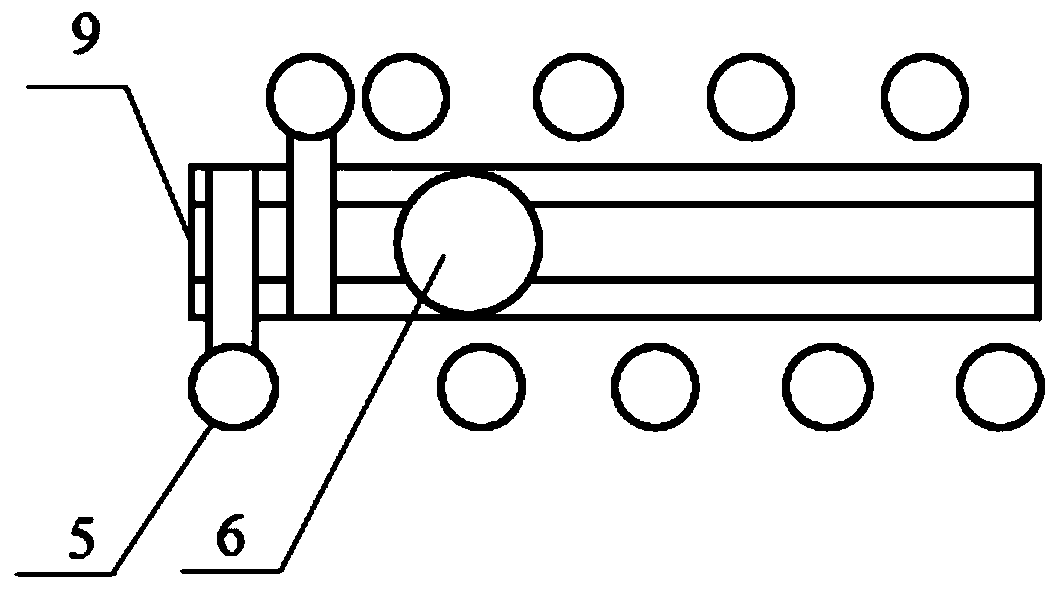

[0037] Embodiment 3, for multi-track scanning thick-walled parts, refer to figure 1 and Figure 5 , an in-situ weaving additive manufacturing method for continuous fiber reinforced composites, comprising the following steps:

[0038] a) Layering and discretizing the data of the three-dimensional components: the multi-track scanning thick-walled part 11 to be printed is dimensioned as a cuboid-shaped part with a length of 50 mm, a width of 15 mm, and a height of 5 mm. The material is PLA composite continuous carbon fiber material. After the three-dimensional data of the solid component is discretely processed, the path is planned and the printing parameters are formulated: the printing path is a reciprocating linear scanning method, the layer thickness is 0.5mm, the scanning distance is 1.0mm, the scanning speed is 1mm / s, and the printing temperature is 210°C;

[0039] b) Pre-grouping and pre-setting the fibers to be woven: for the thick-walled multi-track scanning of the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com