Preparation method of hollow waveguide with silver coating in PEEK plastic pipe

A technology of plastic tube and silver-plated layer, applied in metal material coating process, coating, light guide, etc., can solve the problems of restricting the development of flexible hollow-core waveguide, little research on flexible waveguide, and poor bending resistance, etc. Achieve the effect of improving bonding performance, thermal performance and mechanical performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

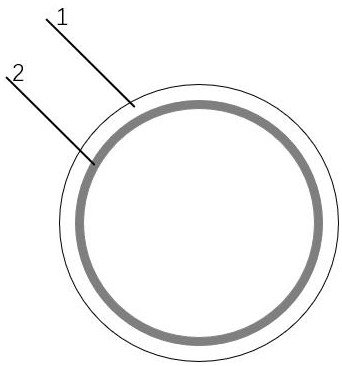

[0033] See attached figure 1 , by plating a silver layer 2 on the structural tube 1 by a liquid-phase chemical deposition method to prepare a hollow-core terahertz waveguide, which specifically includes the following steps:

[0034] 1) A PEEK plastic tube with an inner diameter of 4.25 mm, a wall thickness of 0.35 mm, and a length of 1 m was selected as the structural tube 1, and its inner surface was treated with a plasma gas mixed with nitrogen and hydrogen for 20 min;

[0035] 2) Use a peristaltic pump to sequentially pass detergent, ethanol and deionized water into the structural tube 1 for cleaning. The cleaning time is 2 minutes. The detergent is a mixed solution of detergent and decontamination powder, and its mass ratio 1:1.

[0036] 3) Use a peristaltic pump to sequentially inject SnCl into the structural tube 1 2 Sensitization solution for 5 min, deionized water for 1 min; the SnCl 2 The concentration of the sensitization solution is 8.2 mmol / L;

[0037] 4) Under...

Embodiment 2

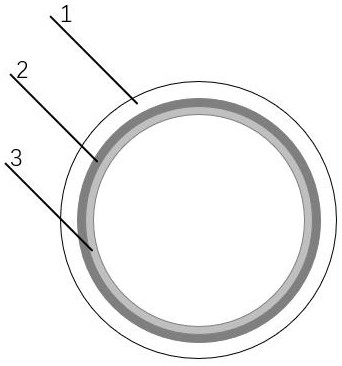

[0042] See attached figure 2 On the inner wall of the structural tube 1, an inner silver-plated layer 2 and a silver iodide reflective film 3 are sequentially prepared to obtain a hollow-core infrared waveguide, and its preparation specifically includes the following steps:

[0043] 1) A PEEK plastic pipe with an inner diameter of 1.0 mm, a wall thickness of 0.2 mm, and a length of 1 m was selected as structural pipe 1, and its inner surface was treated with plasma gas mixed with nitrogen and hydrogen for 30 min;

[0044] 2) Use a peristaltic pump to sequentially pass detergent, ethanol and deionized water into the structural tube 1 for cleaning. The cleaning time is 2 minutes. The detergent is a mixed solution of detergent and decontamination powder, and its mass ratio 1:1.

[0045] 3) Use a peristaltic pump to sequentially inject SnCl into the structural tube 1 2 Sensitization solution for 5 min, deionized water for 1 min; the SnCl 2 The concentration of the sensitization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com