A uniform coating device and method for optical fiber cylinder side

A coating device and optical fiber technology, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problem of poor uniformity of film thickness in the arc direction of optical fiber, which affects the performance and volume of optical fiber reflection, polarization, etc. Large-scale and other problems, to achieve the effect of mass production, easy mass production, and small device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

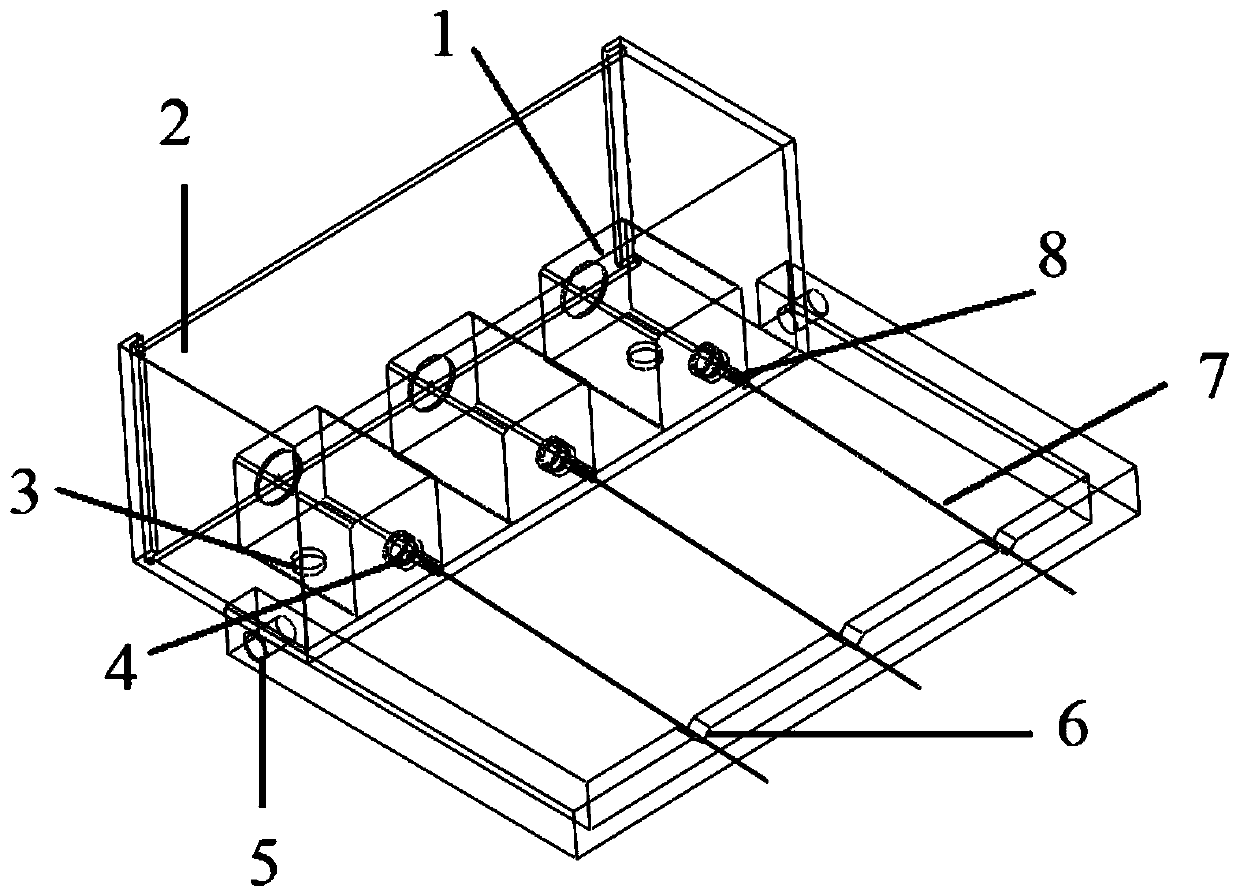

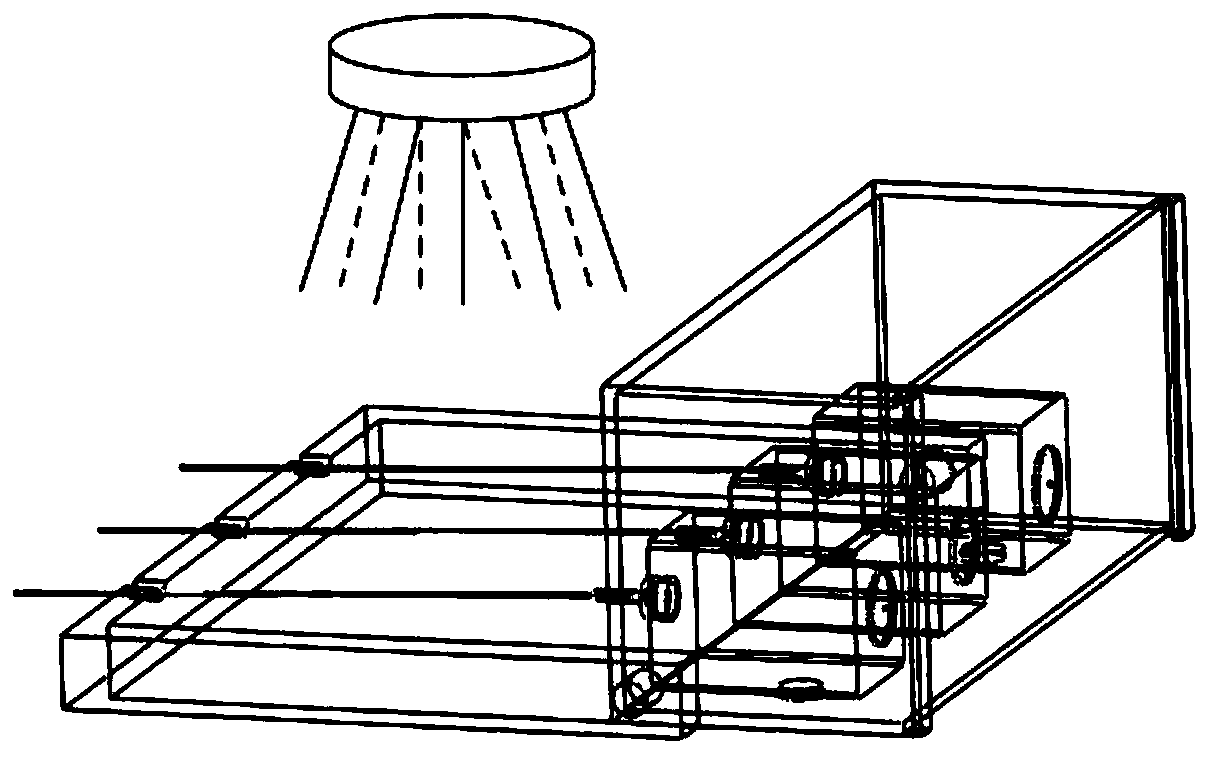

[0029] Such as figure 1 As shown, the optical fiber cylinder side uniform coating device according to an embodiment of the present invention is suitable for coating instruments with coating discs, including a protective rotating structure and an optical fiber supporting structure;

[0030] The protection rotating structure includes an outer frame closure 2, and its vertical side panel is combined with a bottom plate; a plurality of motors and power supply assemblies 1 are arranged on the bottom plate; the vertical side panel of the outer frame closure 2 It can be an integral structure, or it can be formed by plugging multiple side panels.

[0031] The optical fiber support structure includes an optical fiber holder fixed to the outer frame closure 2, and a plurality of V-shaped grooves 6 for placing optical fibers 7 are arranged on the optical fiber holder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com