Reinforcement system by using double-layer prestressing carbon fiber plates

A carbon fiber board and prestressing technology, which is applied in building maintenance, construction, building construction, etc., can solve problems such as insignificant reinforcement effects, failure to meet design requirements, and small prestressing values, so as to reduce deformation and improve applicability Strong, improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

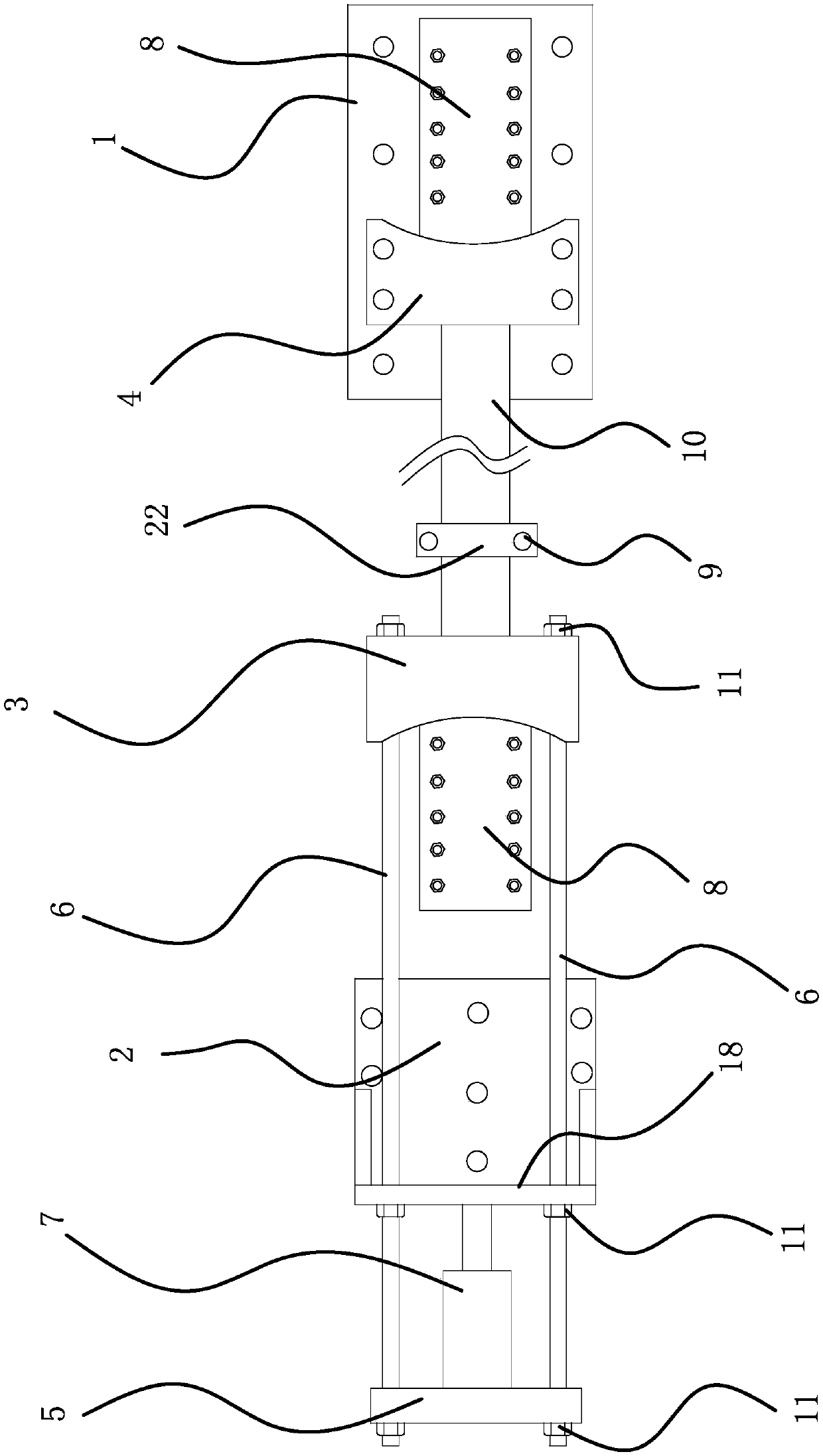

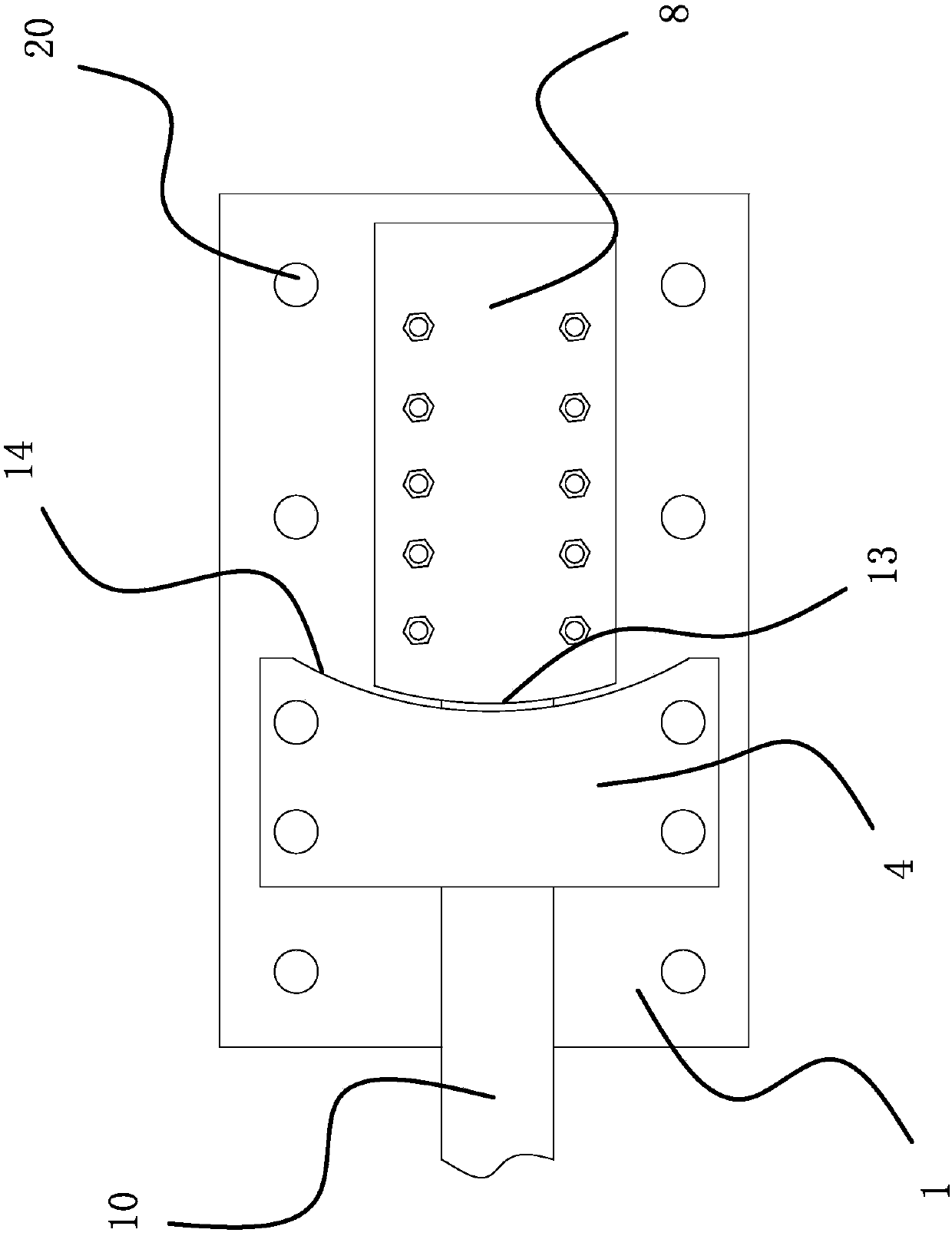

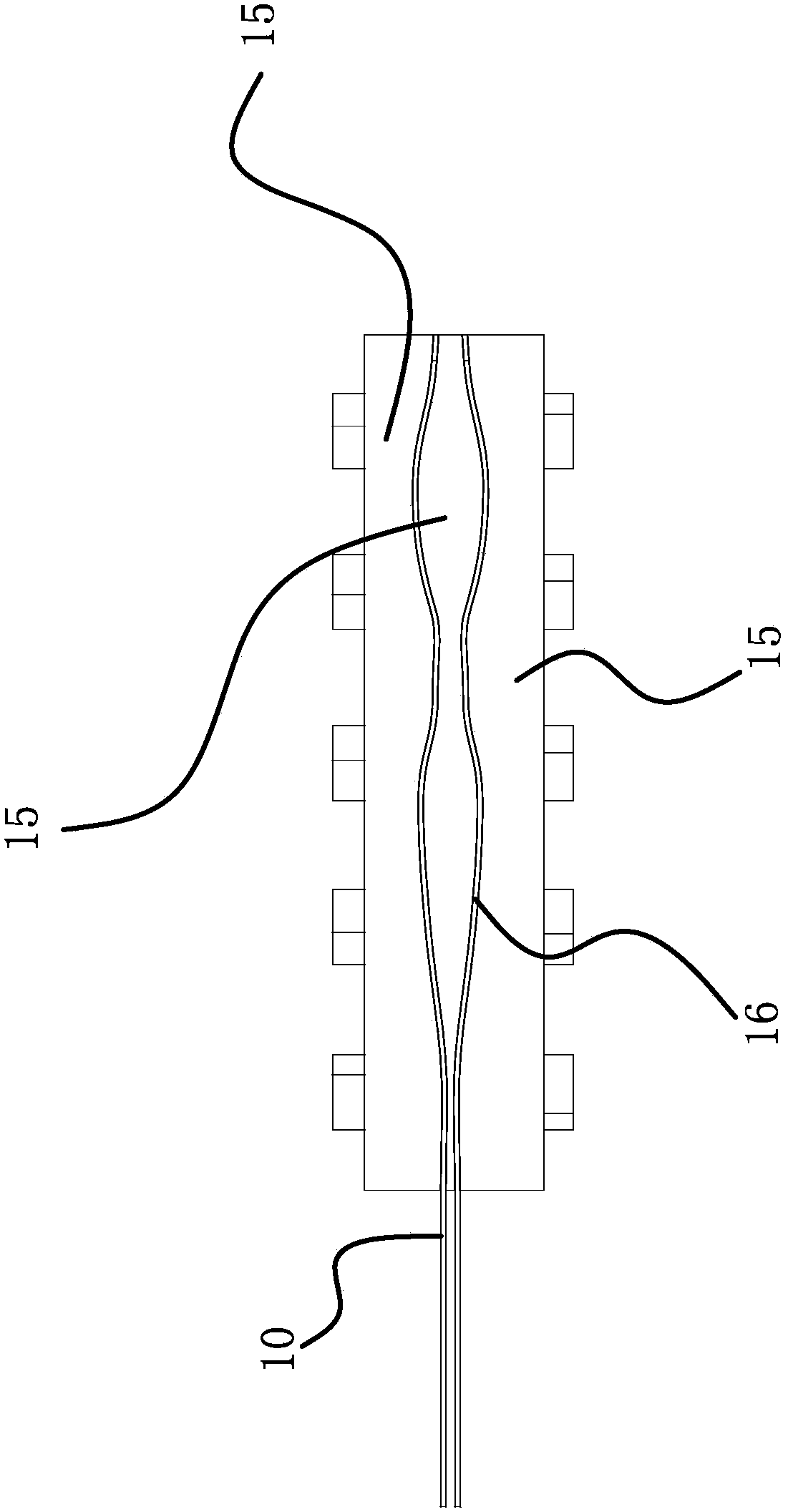

[0026] Such as Figure 1-5 As shown, the double-layer prestressed carbon fiber plate reinforcement system includes a fixed end anchor seat 1, a tension end anchor seat 2, a moving steering head 3, a fixed steering head 4, an end plate 5, a tension threaded rod 6, a jack 7 and a waveform The anchor head 8, the anchor seat 1 at the fixed end and the anchor seat 2 at the tension end are all fixed on the surface of the reinforced object through the anchor bolt 9, and the two ends of the double-layer carbon fiber plate 10 are respectively fixed on the two corrugated anchor heads 8. The anchor seat 2 at the tension end is located between the moving steering head 3 and the end plate 5, the jack 7 leans against the anchor seat 2 at the tension end and the end plate 5, and the fixed steering head 4 is fixedly connected to the fixed end through an anchor bolt 9 for anchoring Seat 1. Two tensioning threaded rods 6 arranged in parallel pass through the end plate 5 , the anchoring seat 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com